Pharmaceutical homogenization skid system

Achieve precise particle size reduction and efficient cell rupture with an autonomous, high-pressure skid system to optimize production of nanoemulsions and liquid formulations.

Processes High-Pressure Homogenization and Nanoemulsion Production

The Plug&Play Pharma Skid is a versatile solution designed by GEA for the pharmaceutical and biotechnology industries. This skid-mounted high-pressure homogenizer serves as an autonomous system, capable of processing tasks such as particle size reduction, cell rupture, and the production of nanoemulsions and nanodispersions under aseptic conditions. It achieves a maximum pressure of 1500 bar, making it suitable for producing vaccines, therapeutic proteins, and other specialized liquid therapeutics.

The Pharma Skid integrates seamlessly into continuous or collective processing lines, with a feed pump featuring a by-pass system, an electrical power board, and multiple customization options including heat exchangers and various measurement instruments to suit unique production needs. In terms of energy efficiency, this equipment allows for significant savings compared to conventional cell disruption systems, thanks to its advanced motor control.

Constructed with a robust material selection to withstand corrosion, the Pharma Skid complies with cGMP and Gamp5 validation standards, ensuring regulatory compliance for the production of pharmaceuticals and nutraceuticals. Additionally, maintenance is streamlined with its clean-in-place (CIP) system, allowing for efficient and contamination-free cleaning. The Plug&Play Pharma Skid is adaptable to various Ariete Series homogenizer sizes, providing flexibility and engineering support for tailored configurations.

Benefits

- Enhances production efficiency with aseptic processing and continuous operation capabilities.

- Reduces energy usage significantly through optimized high-pressure homogenization.

- Ensures compliance with cGMP and Gamp5 standards, supporting stringent regulatory requirements.

- Minimizes cross-contamination risk with integrated clean-in-place (CIP) system.

- Customizable configuration meets diverse production needs, offering flexible process adaptation.

- Applications

- Nanodispersions, Biotechnology, Liquid formulations, Pharmaceuticals, Nanoparticles, Nutraceuticals, Nanoemulsions, Biopharmaceuticals, Pharma food, Pharmaceutical applications, Cell rupture

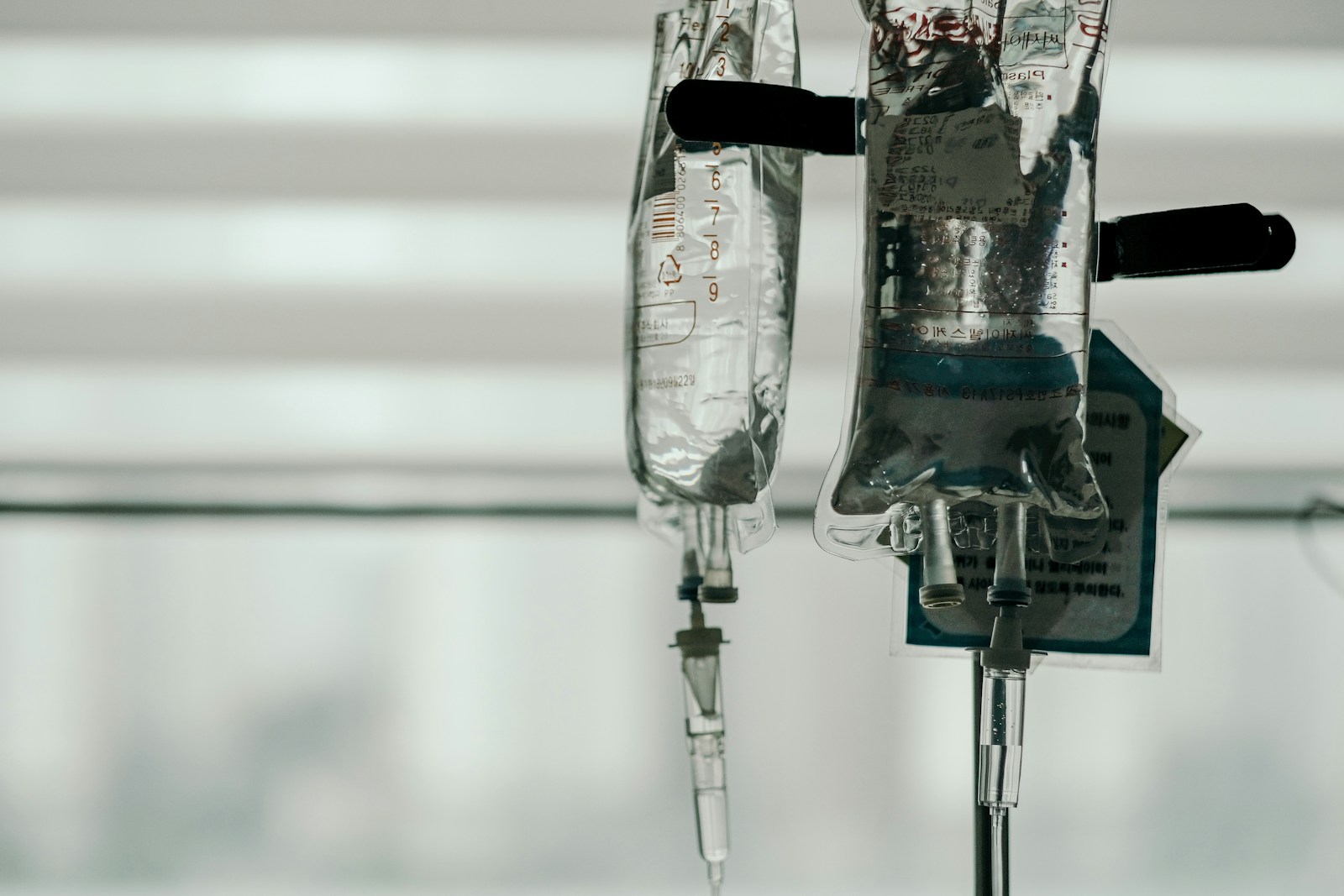

- End products

- Intravenous fluids, Pharmaceutical suspensions, Vaccines, Nano-sized drug delivery systems, Specialized liquid therapeutics, Bioactive compounds, Monoclonal antibodies, Protein shakes, Enzyme preparations, Emulsified nutraceuticals, Lipid nanoparticles, Vitamin capsules, Therapeutic proteins, Dietary supplements

- Steps before

- Purification, Emulsification, Grinding

- Steps after

- Nanoemulsion production, Cell rupture, Particle size reduction, Sterilization, Packing

- Input ingredients

- cell cultures, particles, pharmaceutical ingredients, biotechnology raw materials

- Output ingredients

- cell rupture, nanoparticles, nanoemulsions, nanodispersions, homogenized pharmaceutical solutions

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Pressure capacity

- Up to 1500 bar

- Particle size reduction

- Effective

- Energy savings

- Compared to other systems

- Compatibility

- Pharmaceutical and biotechnology applications

- Yield

- Optimal

- System type

- Autonomous

- Processing applications

- Wide range

- Maximum efficiency

- Yes

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Customizable Production Requirements

- Yes

- Applications

- Pharmaceutical, Biotechnology

- GMP Compliance

- Yes

- CGMP Compliance

- Yes

- GAMP5 Validation Standards

- Yes

- Aseptic Conditions

- Yes

- Machine footprint

- Compact / Skid-Mounted

- System configuration

- Plug, Play

- Skid type

- Pharma Skid

- Operating pressure

- Up to 1500 bar

- Discharge method

- Continuous / Batch

- Control Panel Type

- PLC / HMI

- Integration Possibilities

- SCADA / Factory Automation

- Feed Pump Configuration

- By-pass System

- Heat Exchanger Options

- Available

- Control System for Dust Release

- Available

- Instruments for Measuring Flow Rate

- Available

- Instruments for Measuring Temperature

- Available

- Instruments for Measuring Conductivity

- Available

- Instruments for Measuring Turbidity

- Available