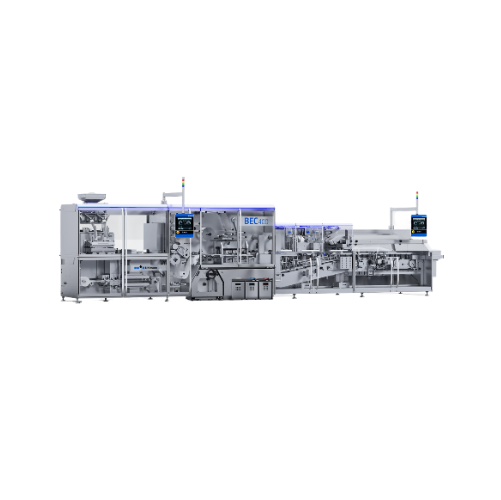

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of goods, from dairy to pharmaceuticals, ensuring precision in filling, conveying, and palletizing processes for optimized efficiency and reduced operational downtime.

Fills and Closes Dairy and Food Products

The Rotary Filling and Closing Machine Type 246 from Trepko exemplifies cutting-edge engineering for efficient food and beverage packaging. This machine specializes in seamlessly filling and sealing products such as milk cartons and yogurt pots, utilizing a rotary mechanism for continuous high-speed operation. Its integration within your production line is effortless, connecting smoothly with upstream and downstream processes like tray erection, pick and place, and palletizing.

The 246 model facilitates automation with its PLC-controlled system, allowing for real-time monitoring and adjustments to maintain optimal throughput. It meets stringent hygiene standards, making it an ideal choice for handling dairy and other sensitive food products. Constructed with durable stainless steel, the machine is corrosion-resistant, ensuring long-term reliability and compliance with industry regulations. Additionally, Trepko offers customization options to tailor the machine to your specific product requirements and production capacity.

Benefits

- Increases production efficiency with continuous filling and sealing.

- Reduces labor costs through fully automated, PLC-controlled operations.

- Ensures product safety with compliance to hygiene standards.

- Durable stainless steel construction for extended equipment lifespan.

- Seamlessly integrates with existing production lines to optimize workflow.

- Applications

- Beverages, Sauces, Detergents, Household goods, Packaged goods, Pet food, Confectionery, Nutraceuticals, Cosmetics, Spices, Food products, Industrial goods, Bakery products, Dairy products, Pharmaceuticals

- End products

- Yogurt pots, Muffin packages, Face creams, Spice jars, Milk cartons, Salad dressings, Laundry detergent bottles, Soap boxes, Tomato sauce jars, Cheese blocks, Dog food cans, Candy bars, Vitamin bottles, Protein powder containers

- Steps before

- Product Preparation, Material Loading

- Steps after

- Palletizing, Final Packaging, Distribution

- Input ingredients

- Output ingredients

- Market info

- Automation

- Fully Automated

- Conveyor System

- 750 SERIES

- Rotary Filling,Closing Machine Type

- 200 SERIES

- Tray Erecting Machine

- 720 SERIES

- Pick,Place Station

- 760 SERIES

- Palletiser

- 740 SERIES

- Brick Forming,Wrapping Machine

- 800 SERIES

- Box Cartoning Machine

- 780 SERIES

- Wrap-around Packers

- 710 SERIES

- Shrink Wrapper

- 730 SERIES

- Automation level

- Fully automated

- Batch vs. continuous operation

- Continuous operation

- System integration

- Filling to palletizing

- Changeover time

- Minimal

- Cleaning method

- Automatic cleaning options

- Energy efficiency

- Optimal for automated systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Customized according to client’s demand

- Machine series

- 200, 720, 760, 750, 740, 710, 800, 780

- Component integration

- Rotary Filling and Closing Machines, Tray Erecting Machines, Conveyers Systems, Palletiser

- Customization

- Set up according to the client’s demand

- Palletizing equipment

- Palletiser (740 SERIES)

- Conveying system type

- Conveyers Systems (750 SERIES)

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Rotary Filling, Tray Erecting, Pick, Place, Palletizing

- Automation level

- Fully Automated