Standalone print & check system for cartons

Ensure data integrity and compliance in packaging operations with a versatile system designed for high-speed serialization, inspection, and tamper-evident labeling.

Prints, Verifies, Labels, and Seals Pharmaceuticals

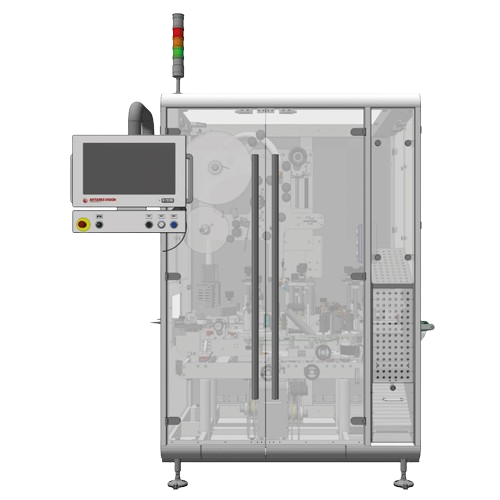

The Print & Check 3T (VM 2600) by Antares Vision Group is an automatic, standalone unit crafted for pharmaceutical and life sciences industries. This machine excels in serialization, with capabilities to print and verify data using inkjet or laser technology, ensuring secure and compliant packaging. It operates effectively in both in-line and off-line setups, handling up to 400 pieces per minute depending on format. Designed for various applications, it processes prescription medications and healthcare goods, featuring tamper-evident sealing and top labelling for enhanced security. Integration is seamless with a user-friendly HMI for centralized control, and it supports real-time data verification through camera-based inspections, ensuring consistent quality and traceability.

Benefits

- Enhances production efficiency with high-speed operation up to 400 pcs/min.

- Ensures compliance and product integrity with reliable serialization and tamper-evident solutions.

- Reduces error rates through integrated camera systems for precise data verification.

- Offers flexible integration with easy switch between in-line and off-line configurations.

- Simplifies user interaction with centralized HMI for streamlined management and control.

- Applications

- Life science products, Nutraceuticals, Healthcare goods, Medicine packaging, Pharmaceuticals

- End products

- Prescription medications, Pill bottles, Liquid medicine bottles, Over-the-counter drugs, Medical devices, Vitamin supplements, Blister packs, Herbal supplements, Dietary supplement capsules, Protein powder sachets, Individual pill packs

- Steps before

- Carton Loading, Label Selection

- Steps after

- Packing, Distribution

- Input ingredients

- carton boxes, variable data, serial numbers, labels

- Output ingredients

- printed boxes, serialized data, verified information, labeled boxes, tamper-evident sealed packages

- Market info

- Antares Vision is renowned for providing inspection, track and trace, and quality control systems primarily to the pharmaceutical, food, and beverage industries, ensuring product integrity and supply chain transparency.

- Line Speed

- Up to 400 pcs/min

- Working Height

- 800-1000 mm

- Conveyor Length

- 1370 mm

- Standard Belt Pitch

- 150 mm

- Standard Carton Size (A)

- 35-120 mm

- Standard Carton Size (B)

- 15-100 mm

- Standard Carton Size (C)

- 50-200 mm

- Print Heads (TIJ)

- Up to 4

- Max Resolution

- 600 dpi

- Datamatrix Print Quality

- Grade B typical

- Up to grade A

- Print Heads (Laser)

- Up to 2

- Number of Cameras for Inspection

- Up to 3

- Top Labelling Label Width

- Up to 60 mm

- Top Labelling External Roll Diameter

- 300 mm (400 mm optional)

- Top Labelling Internal Roll Diameter

- 45 or 76 mm

- Tamper Evident Label Width

- Up to 40 mm

- Tamper Evident Label Length

- Up to 30 mm

- Tamper Evident Gap Between Labels

- 3 mm

- Tamper Evident External Roll Diameter

- Up to 280 mm

- Tamper Evident Internal Roll Diameter

- 45 mm

- Printing sides

- 3 sides

- Printing technology

- TIJ 2.5

- Printing speed

- Up to 400 pcs/min

- Serialization

- Automatic serialization functions

- Label application

- Top labelling and tamper evident

- Data consistency

- Data verification and consistency ensured

- Inspection technology

- Camera-based verification

- Ink Compatibility

- Antares Vision Pharma Black, Industrial Black

- Label Substrate Compatibility

- Up to 60 mm width

- Label Adhesive Compatibility

- Tamper evident applications

- ISO/IEC 15415-2 Datamatrix Quality

- Grade B typical

- Up to grade A on selected backings

- Working height

- 800-1000 mm

- Conveyor length

- 1370 mm

- Standard belt pitch

- 150 mm

- Carton size

- A = 35-120 mm, B = 15-100 mm, C = 50-200 mm

- Label width (top labelling)

- Up to 60 mm

- External roll diameter (top labelling)

- Up to 300 mm (400 mm optional)

- Internal roll diameter (top labelling)

- 45 or 76 mm

- Label width (tamper evident)

- Up to 40 mm

- Label length (tamper evident)

- Up to 30 mm

- Gap between labels

- 3 mm

- External roll diameter (tamper evident)

- Up to 280 mm

- Internal roll diameter (tamper evident)

- 45 mm

- Printing heads

- Up to 4 (TIJ), Up to 2 (LASER)

- Printable sides

- 3 (TIJ), 2 (LASER)

- Line Speed

- Up to 400 pcs/min

- Single HMI

- Yes

- Control panel type

- Single HMI

- Printing technology options

- Ink jet, Laser

- Label application options

- Top and bottom, same side or alternated

- Ink cartridge options

- Pharma Black, Industrial Black