Complete over wrapping for parallelepiped products

Optimize your packaging line with high-speed over wrapping for precision-sealed cosmetic and toiletry products, ensuring perfect protective finishes and operational efficiency.

Wraps and Seals Cosmetic and Toiletry Products

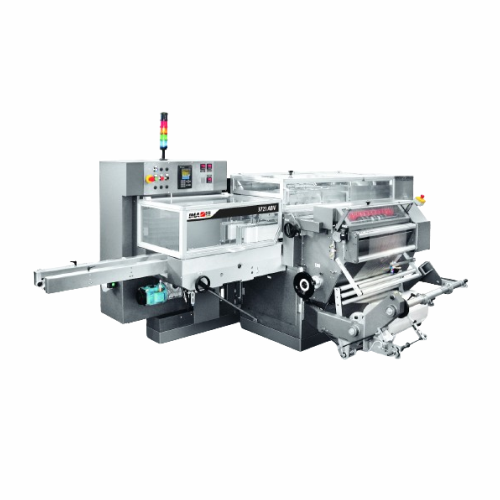

The 3721 Film Overwrapping Machine from IMA Group is tailored for the needs of cosmetic and toiletry manufacturers seeking enhanced packaging efficiency. This machine stands out with its ability to wrap products such as perfume boxes and lotion tubes using various film types, including cellophane and PVC. With a production speed of 80 cycles per minute, it ensures high throughput while maintaining quality. The equipment features automatic reel splicing and a tear tape unit for smooth operation integration in packaging lines. The Siemens PLC and electrical components ensure reliable automation and precise control, while the oil-tight steel frame enhances durability. Designed for quick changeovers, it minimizes downtime and reduces energy consumption by maintaining optimized motion control. Ideal for high-speed, continuous operations, this machine offers customizable options to align with your specific packaging requirements.

Benefits

- Enhances packaging efficiency with high-speed operations of up to 80 cycles/minute.

- Minimizes downtime through quick and easy changeover procedures.

- Ensures product integrity with precise wrapping using extremely thin films.

- Reduces operational costs with automated, PLC-controlled functionality.

- Offers versatile application with compatibility across various film materials.

- Applications

- Toiletry items, Cosmetic items

- End products

- Perfume boxes, Face cream jars, Facial cleanser boxes, Conditioner bottles, Bath salt packages, Toothpaste boxes, Soap bars, Shampoo bottles, Lip balm containers, Lotion tubes

- Steps before

- Cutting, Compression, Product shaping

- Steps after

- Packing, Labeling, Palletizing

- Input ingredients

- cellophane, PVC, PP, heat-sealable film, reel-fed film, extremely thin films

- Output ingredients

- overwrapped products, wrapped cosmetic items, wrapped toiletry items, high quality overwrapped products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Speed

- 80 cycles/min

- Film type compatibility

- Cellophane, PVC, PP, heat-sealable films

- Product dimension range

- Min

- Automation

- PLC-controlled (Siemens PLC)

- Film unwinding method

- Driven drums to move film under guillotine knife

- Sealing units

- Several different sealing units available

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Fast and easy

- Cleaning method

- Designed to facilitate cleaning procedures

- Speed

- 80 cycles/min

- Film Type Compatibility

- Cellophane, PVC, PP, PE, KRAFT

- Thin Film Handling

- Yes

- Heat-sealable Film

- Yes

- Reel-fed Film

- Yes

- Product shape compatibility

- Parallelepiped

- Product type compatibility

- Cosmetic / Toiletry items

- Machine footprint

- Not specified

- Product dimension

- Min

- Film type compatibility

- Cellophane, PVC, PP, KRAFT

- Film thickness support

- Extremely thin films supported

- Control panel type

- Siemens PLC

- Frame material

- Oil-tight steel frame

- Electrical componentry

- Standard Siemens components

- Automation level

- PLC-controlled

- Film print unit

- Available

- Automatic reel splicing device

- Available

- Tear tape unit

- Available

- Reel range

- Biggest on the market

- Sealing unit

- Several different available

- Control panel type

- Siemens PLC