Making Vitamin C

Find innovative production technology for making vitamin c and connect directly with world-leading specialists

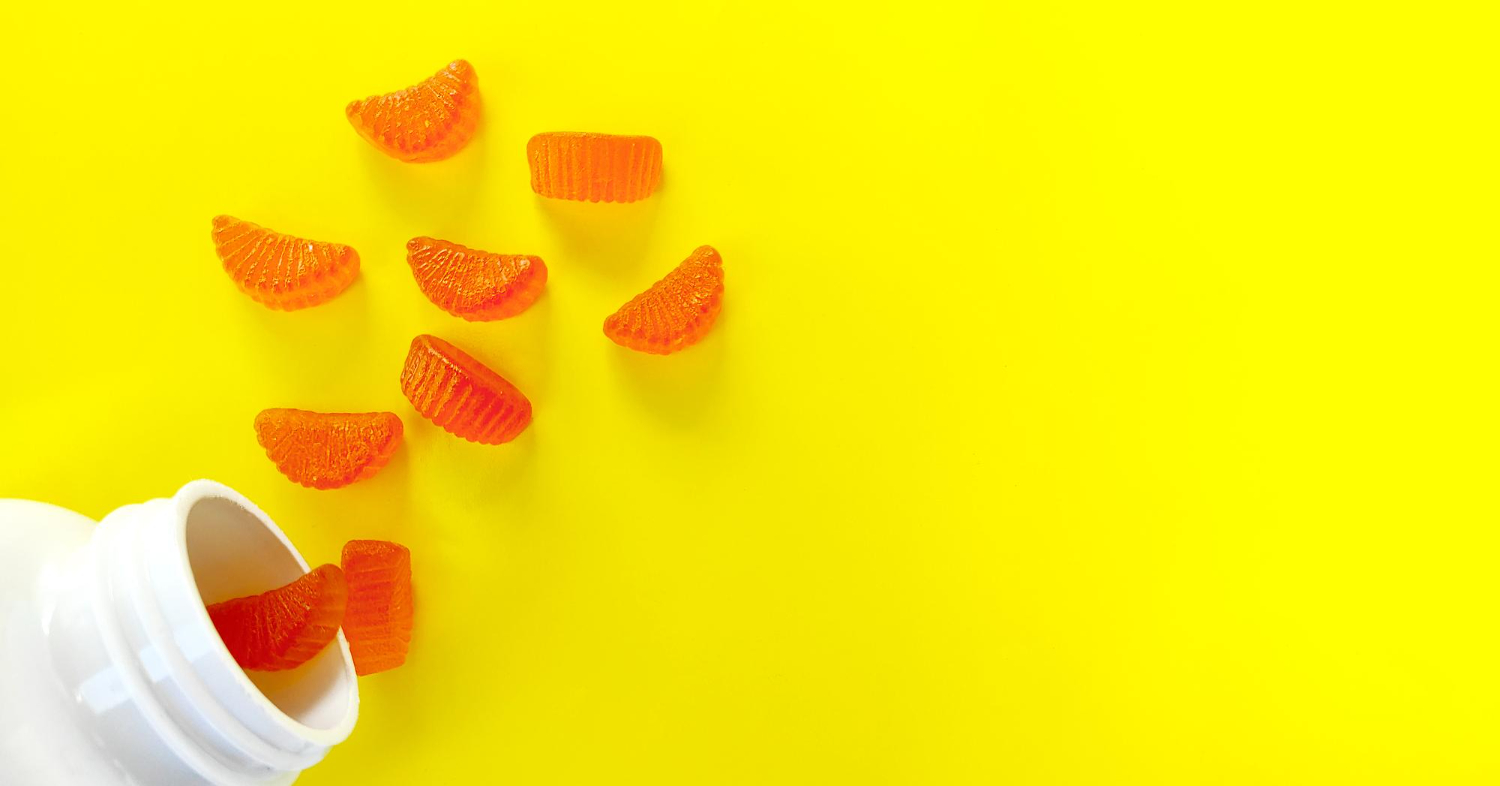

Vitamin C is an essential nutrient, but the human species lost the ability to produce it biologically during the course of evolution. Instead, we source the substance either from whole foods or vitamin C manufacturing. The chemical characteristics of the natural nutrient and processed compound are the same, but supplements offer higher concentrations, especially to persons with nutrient deficiencies.

Select your vitamin c process

Tell us about your production challenge

Sorbitol fermentation achieves nature-identical synthesis of vitamin C

Vegetables and fruits such as kale and lemon are rich sources of vitamin C. But the natural compound is susceptible to light and oxygen, which could dent the extraction yield of processing. Instead, industrial production often relies on crops like corn and wheat for vitamin C manufacturing.

Sorbitol derived from the feedstock undergoes a double cycle of fermentation and filter pressing to synthesize ascorbic acid. The two-step fermentation process recovers around 60% of the product with 95% purity.

Chemically modified disintegrants break up the binders faster

The bioavailability of synthetic vitamin C is identical to that in food-derived vitamins. But the efficacy of supplements also depends on other ingredients besides ascorbic acid.

Disintegrating agents such as cellulose gum or starch facilitate absorption by the body after the dosage is ingested. Meanwhile, advances in this department are developing superdisintegrants that counter the strength of binders to speed up the release of the vitamins.

Add the right lubricants to address sticking issues during production

The flowability of the raw materials presents a significant challenge to vitamin C manufacturing. Apart from risks of caking, lack of flow can result in surface imperfections in the final capsule or tablet. Additives like magnesium stearate or stearic acid act as lubricants to decrease friction between the tablet and the forming die.

Silicon dioxide or other flow agents prevent the formation of lumps as the granules travel along the production line.

Label the packaging quantities in terms of the daily vitamin requirement

As a producer, you must always declare the nutrient reference values (NRV) of vitamin C supplements. International labeling guidelines stipulate that these values should be expressed in metric units or as a percentage of the recommended daily allowance (RDA).

In 2019, the Food and Agriculture Organization set the RDA of vitamin C for adults at 60 milligrams. However, national authorities may establish different quantities. Authorities in the US and EU recommend a daily intake of 80 milligrams for adult females and 90 milligrams for adult males.

Processing steps involved in vitamin C making

Which vitamin c technology do you need?

Lab-scale milling and processing platform

Effortlessly transition from lab-scale research to full production with a versat...

Vacuum cold trap for lab applications

Ensure efficient separation and purification in biopharmaceutical applications with t...

Dry scroll vacuum pumps for laboratories and manufacturing

Ensure a clean, oil-free environment with advanced dry scroll...

Powder sampler systems for food and dairy plants

Ensure precise quality control by implementing advanced sampling techniqu...

Powder unloading systems for food and dairy applications

Streamline your powder handling with customizable unloading syst...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Stickpack filling and closing system for pharmaceutical powders

Achieve precise dosing and secure packaging for pharmace...

Strip packing for solid products

Ensure consistent quality and precision in packaging solid products with this advanced stri...

Electronic counting and filling system for vials

Efficiently streamline the packaging of solid dosage forms with a cutting...

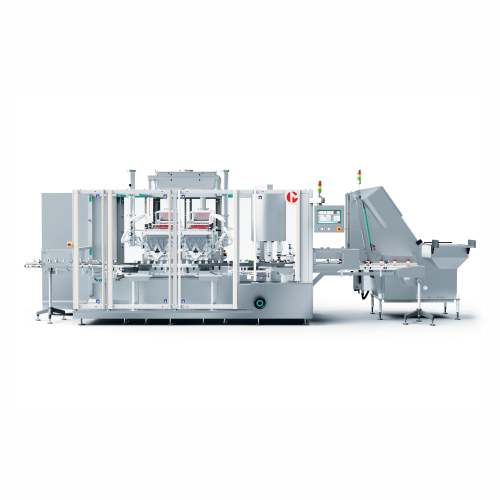

Counting and capping solution for tablets and capsules

Streamline your tablet and capsule production with a high-speed so...

Metal detector for conveyorized applications

Enhance your production line by ensuring product safety with advanced metal d...

Pharmaceutical metal detector for powder and granule inspection

Ensure product integrity by efficiently detecting metal ...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Dust-tight dispenser for metal detector test tablets

Ensure seamless integration of test tablets in high-containment envi...

Vertical vibratory tablet deduster for pharmaceutical tablets

Ensure optimal cleanliness and quality assurance for table...

Tablet deduster with upward conveying

Ensure consistent dedusting and deburring of tablets and capsules while maintaining h...

High performance tablet deduster with metal detection

Achieve precision dedusting and metal detection in tablet processin...

High-containment tablet dedusting solution

Ensure pharmaceutical tablets and capsules meet strict dust control and safety ...

Capsule polisher for pharmaceutical production

Enhance capsule quality and safety by effectively polishing, dedusting, and...

Capsule polisher for pharmaceutical capsules

Ensure your capsules are free from dust and perfectly polished with a solutio...

2-way diverter for tablet and capsule filling

Ensure precision in tablet and capsule filling with seamless batch switching...

Dry sample preparation mil

Optimize your grinding processes with precision particle size reduction for various materials, en...

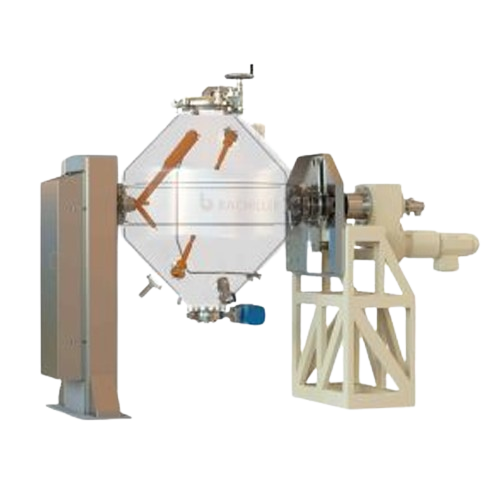

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Vertical intermittent motion stick packaging

Experience seamless packing for diverse products, from powders to dense paste...

Table top tablet and capsule counter

Effortlessly ensure precise tablet and capsule counts with solutions that seamlessly i...

Medium speed blister packaging solution for pharmaceuticals

Optimize medium-speed tablet blister packaging with seamless...

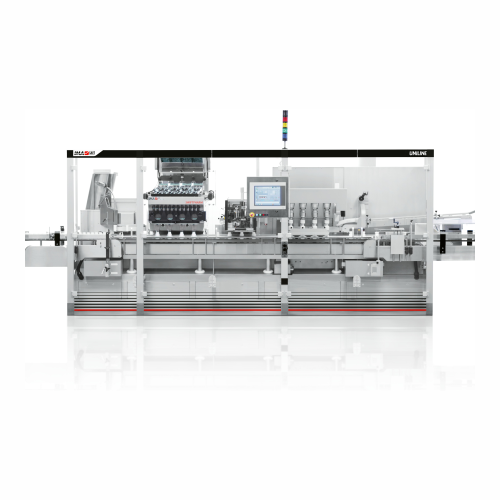

Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that se...

High shear mixer granulator for pharmaceutical applications

Achieve optimal granulation with precise shear control, enha...

Fluid bed and coating system for small batch processing

Streamline your R&D process with a modular system that ensur...

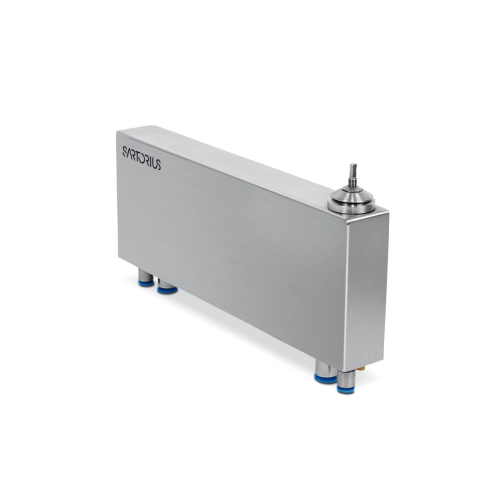

Industrial washing skid for pharmaceutical components

Ensure precise cleaning and drying of pharmaceutical components wit...

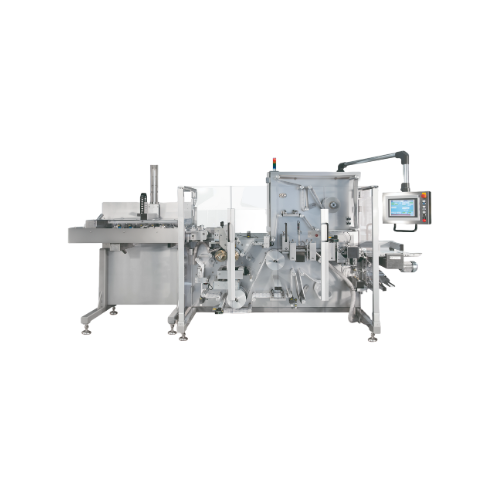

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

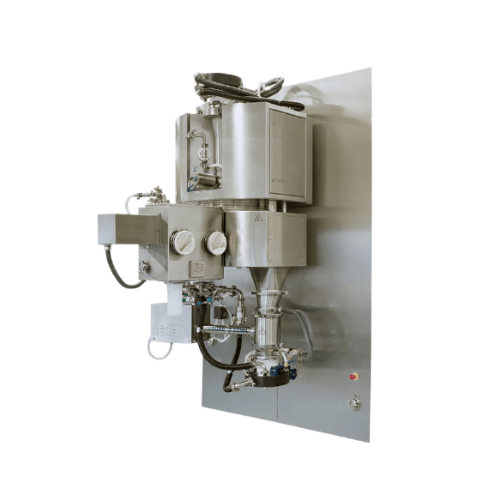

Fluid bed processor for pharmaceutical granulation and drying

Achieve precise drying, granulation, and coating of pharma...

Blister packaging solution for small-medium batches

Achieve unparalleled versatility and efficiency in blister packaging ...

Blister packaging solution for small/medium batches

Achieve high production efficiency with frequent changeovers for your...

Tablet press for high-quality pharmaceutical tablets

Ensure optimal tablet quality and yield with an advanced compression...

Tablet pressing system for solid chemicals and cosmetic products

Optimize your tableting process for diverse solid produ...

Pure steam generation and distribution system

Ensure reliable sterilization with pure steam that’s free from contami...

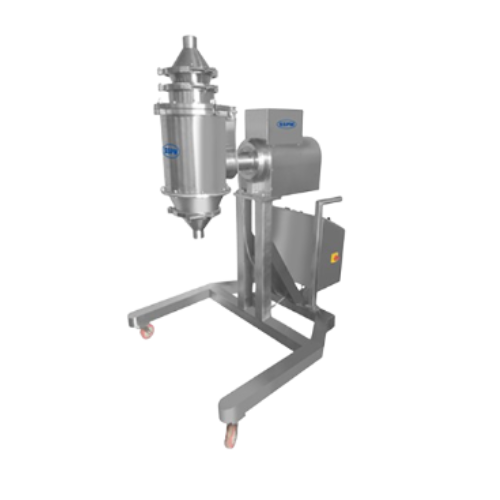

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

Laboratory vacuum milling for fine particle size reduction

Streamline your lab and pilot processes with high-speed vacuu...

Hydrogen compression solution for refueling stations

For operations demanding efficient hydrogen compression, this modula...

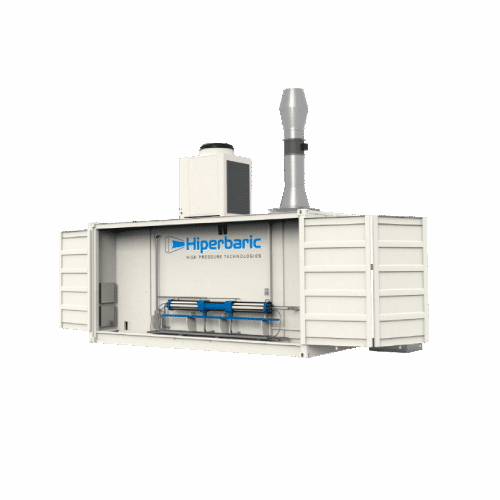

High pressure processing for bulk liquid beverages

Streamline your liquid processing with high-pressure in-bulk technolog...

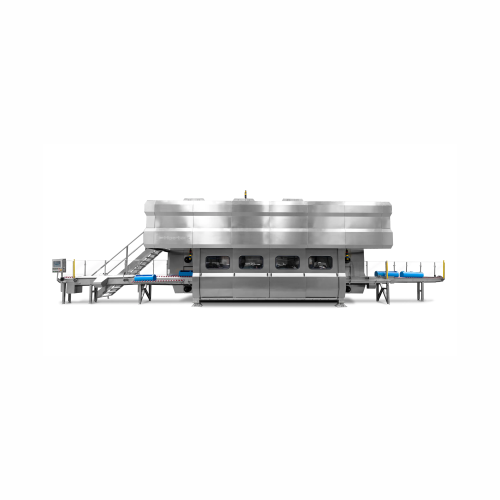

High pressure food processing system

Achieve extended shelf life and enhanced food safety with a cutting-edge high-pressure...

Compact food drying system

Achieve precise moisture control for product development and testing with this versatile compact ...

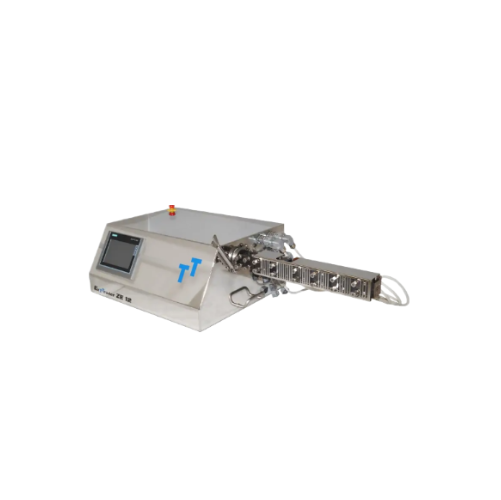

Single-color inline digital printer for blister-lidding foils

Streamline your pharmaceutical packaging with precision pr...

Tablet storage and transport containers

Ensure the safe and gentle handling of tablets during storage and transport, minimi...

Rotary crushing valve for lump breaking

When handling bulk solids, effective pre-breaking and sizing are crucial to ensure ...

High-accuracy rotary dosing valve for fine material feeding

Ensure precise dosage of fine powders and granules, enhancin...

Industrial container and drum handling solution

Effortlessly maneuver and position heavy containers such as IBCs and drums...

Ibc tumbler for uniform batch mixing

Achieve consistent and homogenous mixing of powders, granules, and solid products with...

Capsule conveyors for gentle capsule transfer

Streamline your capsule production line with a system designed for high-spee...

Vacuum paddle dryer for active pharmaceutical ingredients

For precise moisture control and contamination-free conditions...

Spherical vacuum dryer for Apis and fine chemicals

Achieve precise moisture control and efficient drying for APIs and fin...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

Laboratory conical screen mill for powder calibration

Achieve precise particle size control with this compact laboratory ...

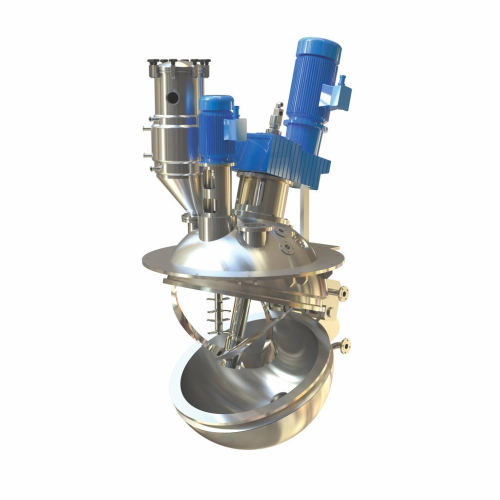

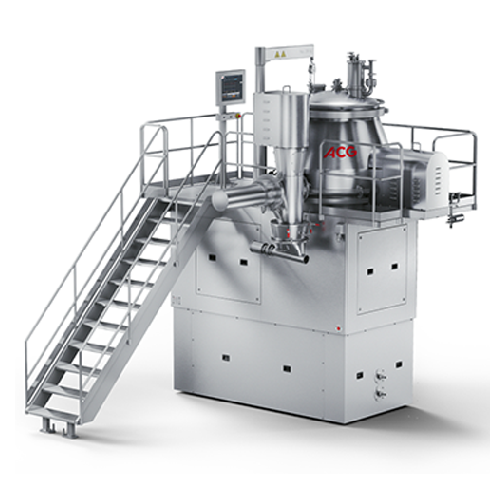

High shear granulation mixing system

Optimize your powder granulation process with a system designed for precise control ov...

High shear wet granulation line

Achieve consistent and uniform granules with energy-efficient wet granulation designed to op...

Roll compactor system for dry granulation

Achieve consistent tablet hardness and increased powder density with a versatile...

Roller compaction system for dry granulation

Achieve precise densification and consistent powder granulation with a system...

Dry granulation system for powder compaction

Achieve consistent sheet hardness and increased density in powdered materials...

Benchtop roller compacting system

Achieve precise powder densification and uniform dry granulation with this compact system...

Centrifugal sifter for particle size classification

Achieve precise particle size control with high output efficiency, en...

Conical screen mills for powder calibrating

Achieve precise particle size distribution for your powders and granules with ...

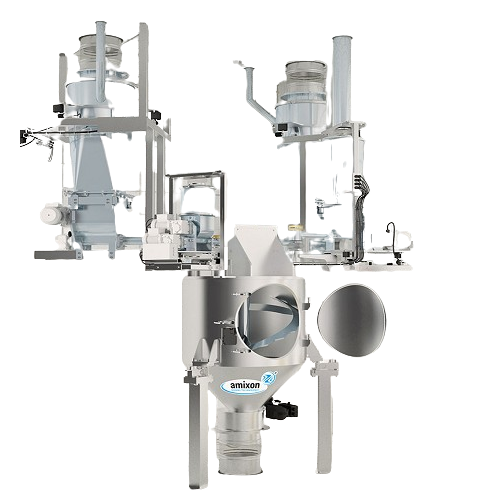

Pharmaceutical powders and granules dry blending

Achieve uniform blending of diverse powder and granule formulations with ...

Continuous direct compression system for tablet production

Achieve seamless continuous direct compression by integrating...

Industrial tablet press for high output production

Achieve precise control and efficient production with advanced rotary ...

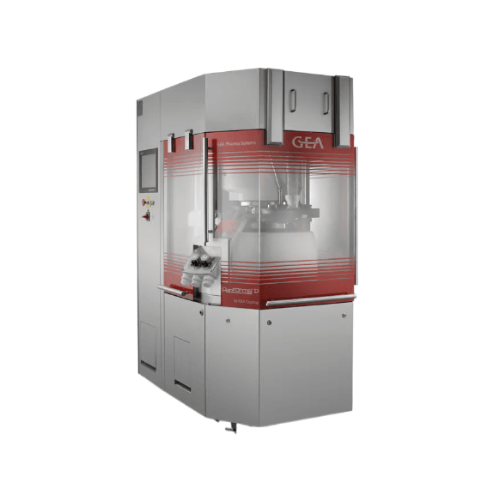

Closed loop granulator for pharmaceutical production

Streamline your production with a fully automated closed-loop system...

Internal and external bin washing cabinet

Streamline your sanitation process with automated bin cleaning that ensures thor...

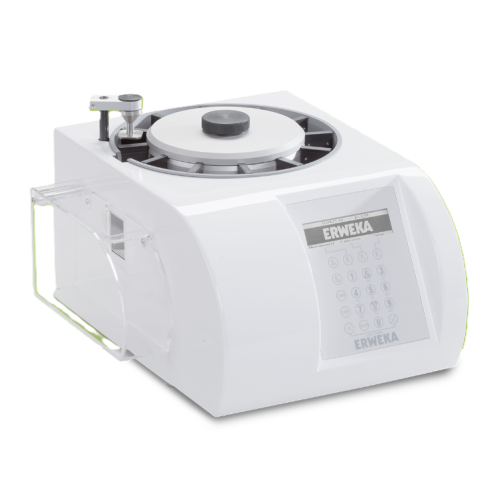

GMP automatic tablet hardness tester

Ensure precise control over tablet quality with a fully automated tester that seamless...

Tablet hardness and combination tester

Ensure consistent tablet hardness and precision across multiple parameters with this...

Tablet hardness tester for pharmaceutical quality control

Ensure precise tablet hardness measurement to enhance pharmace...

Drum hoop mixer for uniform three-dimensional mixing

Achieve consistent, homogenous mixing of powders and granules with a...

Laboratory high speed mixer for powders and granules

Achieve homogenous blending of powders and granules efficiently with...

pharmaceutical-tablet hardness testing system

Ensure consistent tablet quality and compliance with pharmacopeia standards ...

Advanced friability and abrasion testing solution

Ensure precise compliance in pharmaceutical tablet testing with this in...

All-purpose mixer and processor for laboratory and small scale production

Optimize your small-scale production with a ...

Double roll crusher for laboratory applications

Optimize material processing with a double roll crusher designed for preci...

Wet granulator for pharmaceutical applications

Achieve precise granule consistency with advanced oscillating rotor technol...

Dissolution testing system with Hplc analysis

Streamline your dissolution testing with integrated HPLC analysis, offering ...

Dissolution testing software for compliance and efficiency

Ensure data integrity and streamline compliance with a robust...

Automatic dissolution testing for sustained release dosage forms

Effortlessly simulate pH changes for accurate dissoluti...

High volume dissolution tester for pharmaceutical research

Achieve precise dissolution testing of tablets across two bat...

Horizontal flat pouching line for liquid soaps

Streamline your liquid product packaging with a dual-lane flat pouching lin...

Elevator tipper for flexible dough handling

Achieve maximum flexibility in your production line with a versatile lifting s...

Fluid bed processor for granulating, drying, and coating in pilot scale

When scaling from laboratory to production, rel...

Ibc and drum filling system for chemical substances

Ensure safe and efficient handling of sensitive materials with a modu...

Evaporative crystallizers for chemical processing

Optimize your crystallization process with state-of-the-art evaporative...

Industrial evaporators for diverse applications

Maximize energy efficiency and reduce operational costs with cutting-edge ...

Benchtop laboratory powder blender

Perfect for R&D labs needing precise, small-batch powder blending and mixing, this ...

Distillation equipment for large reactors

Efficiently achieve high-purity separations and syntheses with distillation equi...

Large-scale industrial freeze dryer

Achieve precise moisture control and preserve product integrity with a large-scale free...

Pharmaceutical bottle unscrambler

Streamline your pharmaceutical packaging process by efficiently sorting and aligning bott...

Laboratory cone mill for even grinding

Achieve consistent particle size for laboratory powders with precision calibration a...

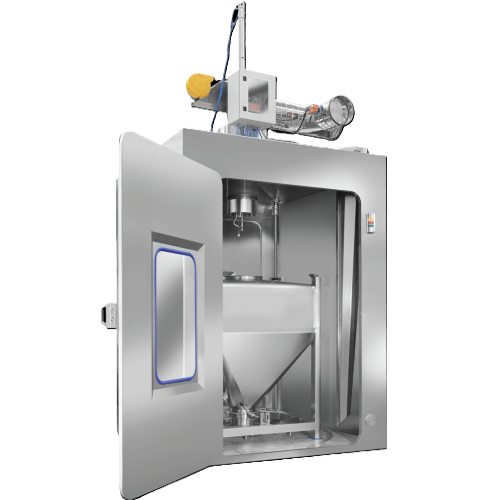

Dry powder filling isolator for cgmp production

Achieve precise powder dosage and secure containment for hazardous materia...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Tablet counting solution for pharmaceutical industry

Maximize dosing precision and reduce miscounts in high-speed pharmac...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

High containment powder transfer valve for bulk material

Ensure operator safety and prevent cross-contamination with robu...

Clean room oven for class 100 environments

Achieve precise temperature control and maintain particle integrity in critical...

High speed blister packaging for pharmaceutical industry

Ensure precision and speed in pharmaceutical packaging with a hi...

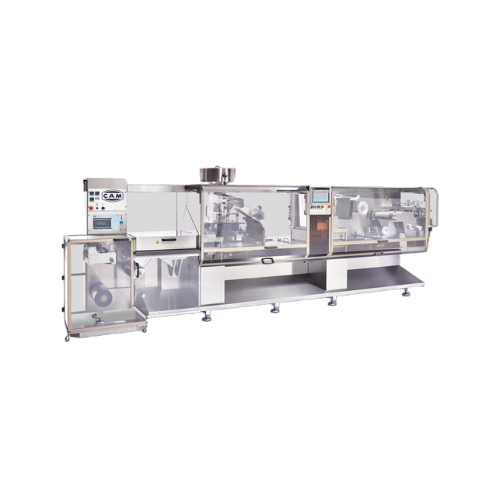

Intermittent motion horizontal cartoner for large products

Simplify your packaging process with a solution that ensures ...

Blister packaging for pharmaceutical products

Facilitate seamless packaging of pharmaceuticals with a solution designed to...

Continuous motion powder dosing system

Ensure precise dosing of pharmaceutical and nutritional powders with this continuous...

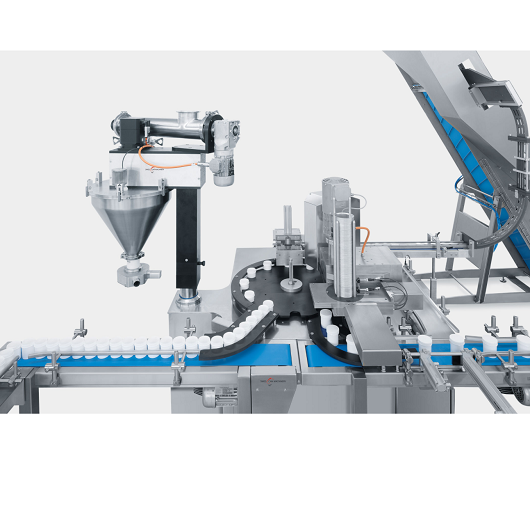

Intermittent motion powder dosing and capping system

Ensure precise powder dosing and secure capping in one seamless step...

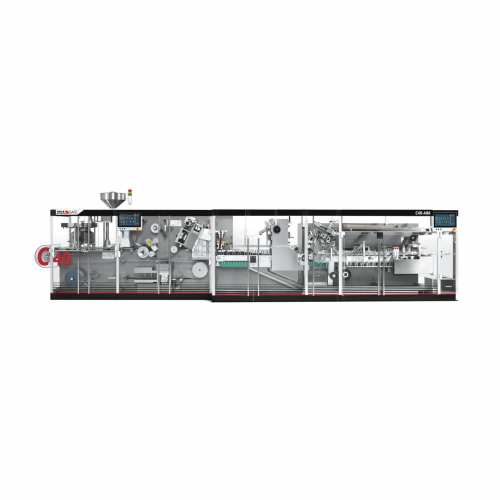

High-speed strip packaging for tablets and capsules

Optimize your high-speed pouching operations with precise four-side s...

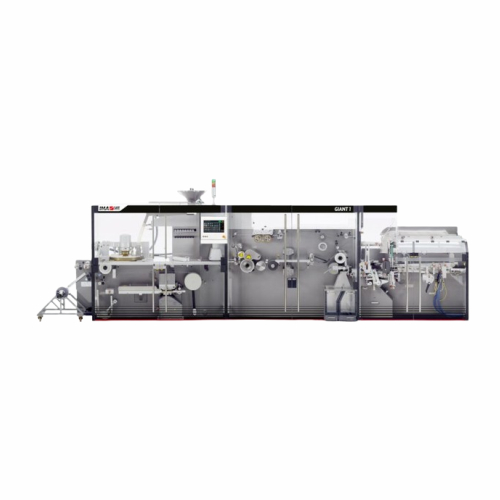

High speed strip packaging for tablets and capsules

Ensure precise packaging of pharmaceutical tablets and capsules with ...

Vertical ribbon vacuum dryer for thermosensitive products

Achieve optimal drying of thermo-sensitive materials like powd...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Vertical conical screw vacuum dryer

Achieve precise moisture control with ultra-vacuum batch drying, ideal for thermo-sensi...

Double cone mixer for powders and solids

Ensure gentle mixing of fragile powders and solids with a low-speed, non-forced bl...

Double cone vacuum dryer for thermosensitive products

For precise drying of heat-sensitive powders, this double cone vacu...

Precise weighing solutions for small batch production

Streamline handling of diverse ingredient blends with precise dosin...

Precise dosing system for bulk materials

Ensure precise bulk material dosing with minimal dust, seamlessly switching betwee...

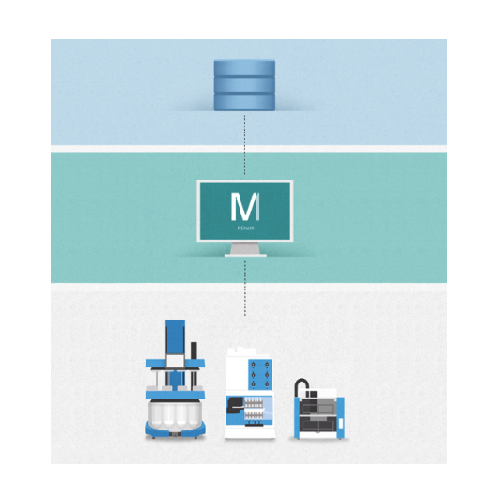

Batch automation system for fast and precise weighing

Achieve unmatched precision and speed in batch processing with this...

Automated bulk material handling system

Ensure precise batch tracking and efficient handling of challenging bulk materials ...

Automatic visual inspection for sterile preparations

Ensure the integrity of sterile products with precise visual inspect...

Continuous wet granulation equipment

Achieve optimal particle size and uniformity in pharmaceutical production with our con...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Large batch gyraton® mixer for homogenizing moist and poorly flowing materials

Optimize your production line with this...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Pharmaceutical roller compactor for dry granulation

When precision and uniformity in tablet production are crucial, optim...

Lifting column for plastic boxes in pharmaceutical processing

Optimize your tablet and powder processing by seamlessly l...

Powder dosing and weighing system

Optimize precision in pharmaceutical processing with a system designed to ensure accurate...

Pharmaceutical freeze dryer for medium scale production

Ensure optimal preservation of active ingredients through precise...

Analytical balance for precise laboratory measurements

Achieve unparalleled precision and reliability in your lab’s...

100l laboratory jacketed glass reactor

Optimize your batch processing with this 100L jacketed glass reactor, designed for p...

150l jacketed glass reactor for chemical synthesis

Achieve precise control over complex chemical processes with this sing...

Intermediate-scale fluid bed system for drying and granulation

Achieve precise drying and granulation with this versatil...

Fluid-bed granulator for top-spray applications

Need precise granulation and drying for sensitive materials? This fluid-be...

Fluid-bed drying and granulation system

Optimize your production line with high-speed batch processing for efficiently dryi...

Integrated granulation train for pharmaceutical processes

Achieve precise granulation, uniform mixing, and efficient dry...

High-shear mixer for large-scale pharmaceutical production

Optimize your granulation process with an advanced high-shear...

Capsule filler for high-speed, dust-free capsule production

Enhance your production efficiency with a solution designed ...

Fluid bed combo for granulation and coating

Achieve seamless granulation and coating with batch and high-speed operations,...

High-output blister packaging system

Maximize blister packaging efficiency with continuous-motion capabilities, ensuring su...

Rotary blister packaging for tablets and capsules

Optimize your blister packaging with high-performance rotary forming an...

Intermittent motion cartoning machine for blister packs

Optimize your packaging line with a space-efficient cartoning mac...

Flat forming and sealing blister packaging solution

Enhance your blister packaging process with a solution that ensures p...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Bottomless conveyor for 90° bottle transfer and coding

Efficiently connect disparate production systems in your bottling ...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

Accumulation turntable for bottling lines

Optimize your production line’s efficiency with a 42-inch diameter accumul...

Automatic inline tray sealer for food packaging

Streamline your packaging process with high-speed, reliable tray sealing t...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

Rotary tablet press for pharmaceutical industries

Optimize your tablet production with swift format changeovers and bi-la...

Heavy-duty tablet press for single & double-layer tablets

Maximize your tablet production with a high-speed solution cap...

Medium-volume rotary tablet press for pharmaceuticals

Optimize tablet production with high-throughput and rapid changeove...

Micro-ingredients doser for precise powder additives

Maintain precision and hygiene in your production line with a specia...

Rotary cleaner for raw material sieving

Ensure precise raw material quality with a rotary cleaner that efficiently sieves a...

Intermediate bulk container (ibc) blending for pharmaceutical manufacturing

Streamline your pharmaceutical blending pr...

Pharmaceutical homogenization skid system

Achieve precise particle size reduction and efficient cell rupture with an auton...

Pharmaceutical freeze dryer for large-scale production

Streamline your freeze-drying process with precision-engineered ly...

Single pot processor for granulation and drying

Streamline your pharmaceutical production with an integrated solution that...

Fluid bed processing of pharmaceuticals

Enhance your pharmaceutical production with versatile fluid bed processors, enablin...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

Pure steam generator for industrial applications

Ensure the highest levels of steam purity and precise pressure control fo...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

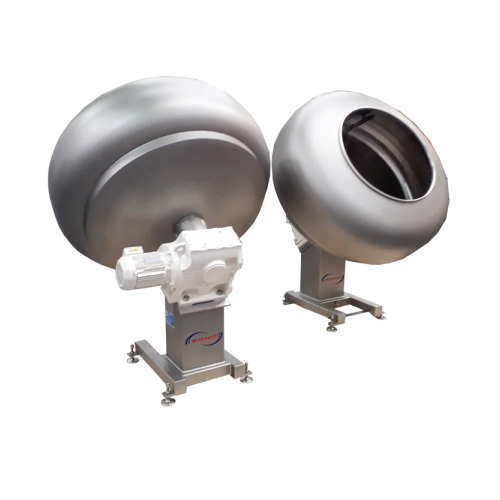

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Double cone mixer for free-flowing material blending

Optimize your production with precision blending and gentle drying o...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Rotary homogenizer for laboratory and pilot plant

For achieving optimal dispersion in complex formulations, this solution...

Dissolver for mixing and processing in lab and pilot plant

Optimize your material dispersion and homogenization processe...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Cartoning solution for pharmaceutical products

Ensure accurate and efficient packaging of pharmaceutical products with pre...

Servo multi piston depositor for bakery production

Streamline your bakery production with precise portion control and hig...

Single piston food depositor for temperature-sensitive environments

Optimize your production with a versatile depositor...

Multi-effect water distillator for pharmaceutical applications

Ensure your production line meets stringent regulatory st...

Table-top mini extruder for precision material processing

Achieve precise control over complex formulations with this fl...

Volumetric twin-screw feeder for poorly flowing powders

For manufacturers dealing with powders that clump or cake, this f...

Small-scale twin-screw feeder for powder handling

Perfect for precision in lab environments, this small-scale feeder effi...

Isolator high containment for granule production

Ensure high-purity production in pharmaceuticals with controlled granulat...

Volumetric flat-bottom twin-screw feeder for powders

When handling powders prone to clumping, a reliable feeder ensures u...

Quick change feeding devices for industrial applications

Experience seamless product transitions with quick-change feedin...

Volumetric single-screw feeder for fine dosing

Achieve precise and consistent dosing of fine powders and granules with a c...

Industrial metal detector for food and beverage applications

Ensure your production line is free from metal contaminants...

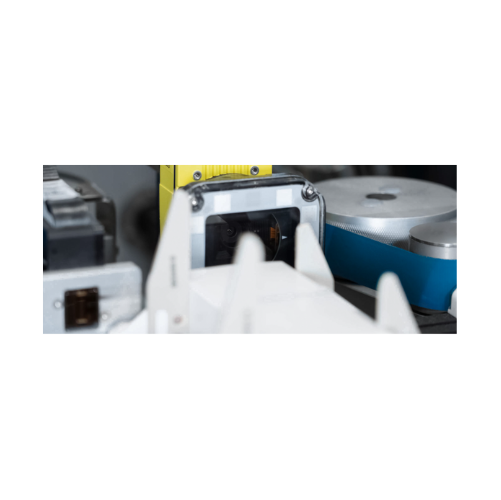

Pharmaceutical metal detector for tablet presses and capsule filling

Detect and eliminate metal contaminants in high-sp...

Vision-based robotic feeding system

Enhance your production line with precise robotic feeding, optimizing product placement...

High-speed double twist packaging system for soft caramels

Streamline your confectionery packaging process with a high-s...

High speed packaging system for fold wrap and stick packs

Streamline your confectionery production with a versatile syst...

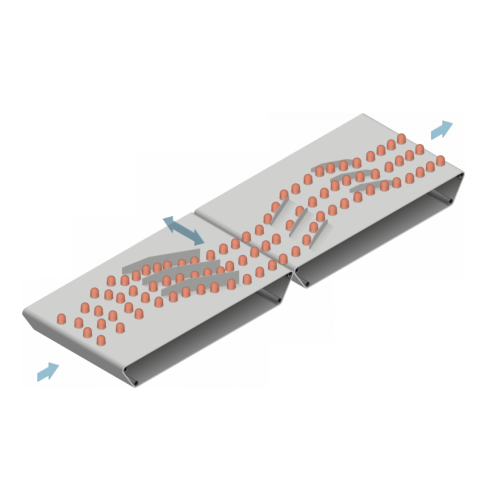

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

Twin-lane high-speed forming, cutting, and wrapping system

Achieve unparalleled packaging efficiency with a high-speed t...

High speed packaging system for soft caramels

Optimize your confectionery line with a high-speed solution designed to seam...

High-speed wrapping solution for compressed powder products

Efficiently wrap high-volume compressed powder products with...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Volumetric auger filler for powder packaging

Streamline your powder packaging process with precise and efficient volumetri...

Lab scale hammer mills for fine particle size reduction

Optimize your R&D scaling efforts with versatile lab equipme...

Dry heat sterilization and depyrogenation oven for glassware

Achieve precise sterilization and depyrogenation of glasswa...

Sublimation front monitoring system for freeze drying

Ensure precise control over your freeze-drying process with real-ti...

Tablet compression technology for pharmaceutical production

Enhance your production capabilities with advanced tablet co...

Capsule filling for nutrition and health products

Optimize your production line with advanced capsule filling capabilitie...

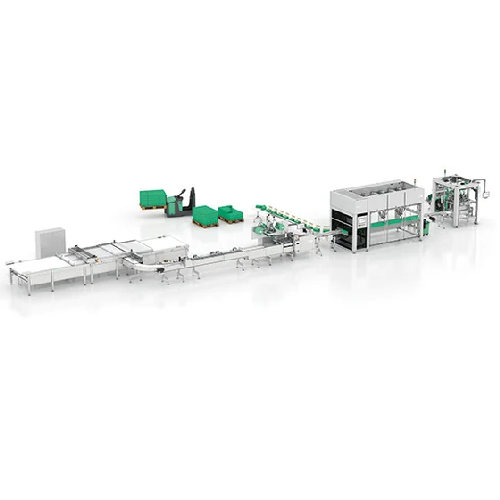

Nutraceutical products processing and packaging

Streamline your nutraceutical production with versatile equipment capable ...

Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with ...

Pharmaceutical aseptic separator tumble dryer

Streamline moisture reduction with precision: this solution accelerates dryi...

Material handling system for granules and powders

Optimize your production with seamless material handling specifically d...

Wet granulation for pharmaceutical products

Achieve seamless integration of sifting and milling with precise powder handli...

Dry granulation roll compactor

Optimize your tablet and capsule formulation by efficiently compacting and granulating powder...

Fluid bed dryer for wet granulation in pharmaceutical industry

Streamline your production with fast, uniform drying and ...

High-speed sifting for safety screening in pharmaceutical production

Achieve precise particle sizing with a high-speed ...

Steam/electrical kettle for wet granulation processes

Achieve precise moisture content and uniformity in your granulation...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Pneumatic conveying system for dry bulk powders

Ensure seamless and contamination-free transfer of pharmaceutical powders ...

Industrial batch mixer agitators

Achieve precise and efficient mixing of diverse materials with industrial batch mixer agita...

Single-use batch chromatography systems for biopharmaceuticals

Streamline your purification process with high productivi...

Infrared moisture analyzer for lab and production use

Achieve precise and reliable moisture analysis with minimal time an...

High-accuracy moisture analyzer for lab weighing

Achieve precise and reproducible moisture content determination for diver...

Semi micro and micro weighing cells for lab weighing

Achieve unparalleled precision in your laboratory measurements with ...

Lab punching and sealing system for cleanroom conditions

Test and refine your packaging processes with precision, ensurin...

Production system for molecular diagnostics

Eliminate bottlenecks in molecular diagnostics production with a versatile sys...

Capsule printer for pharmaceutical applications

Experience precise dual-color printing with high-speed efficiency for caps...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

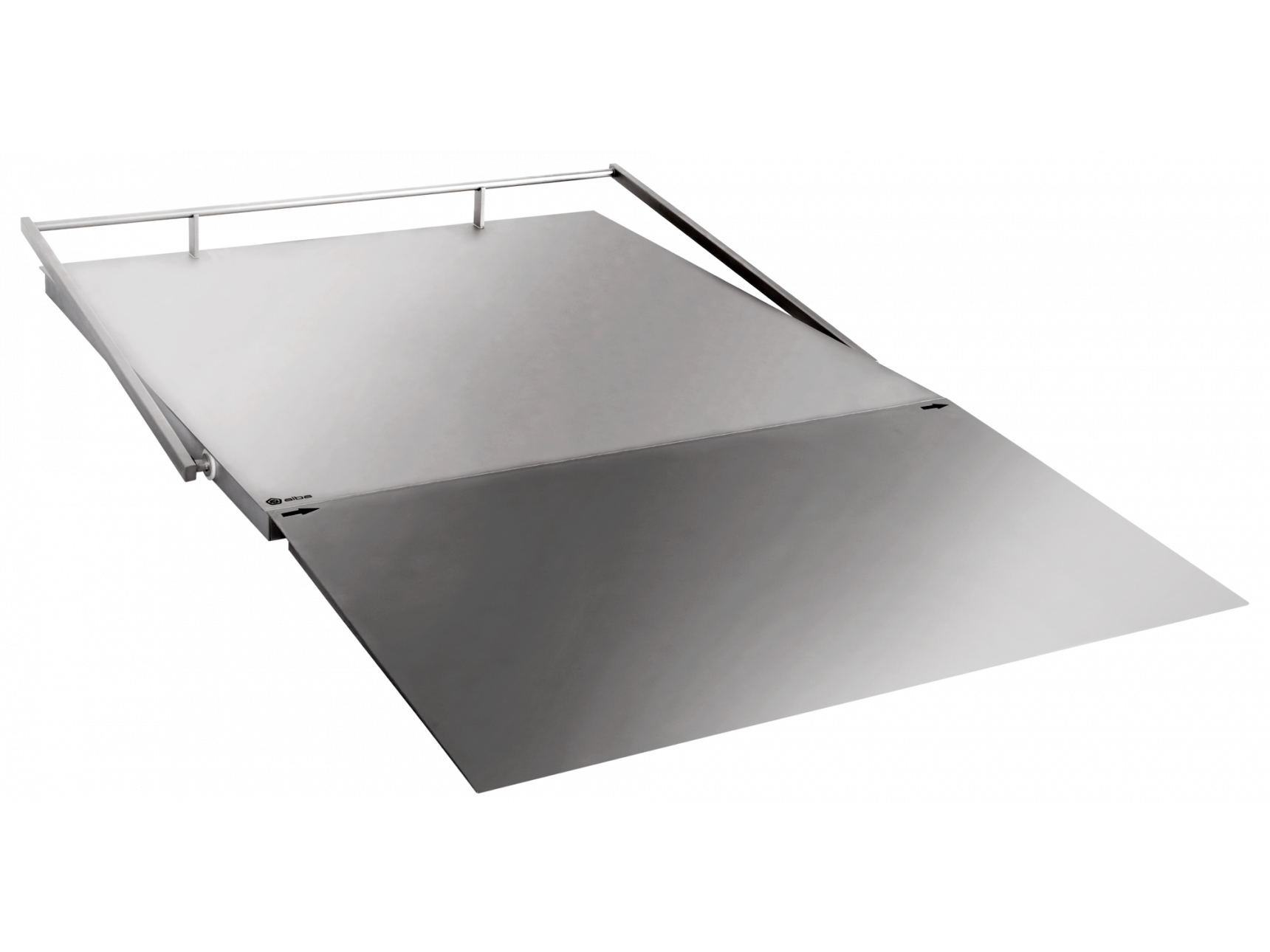

Hygienic floor scale

The food and pharmaceutical industries require maintaining high levels of sanitations as well as logisti...

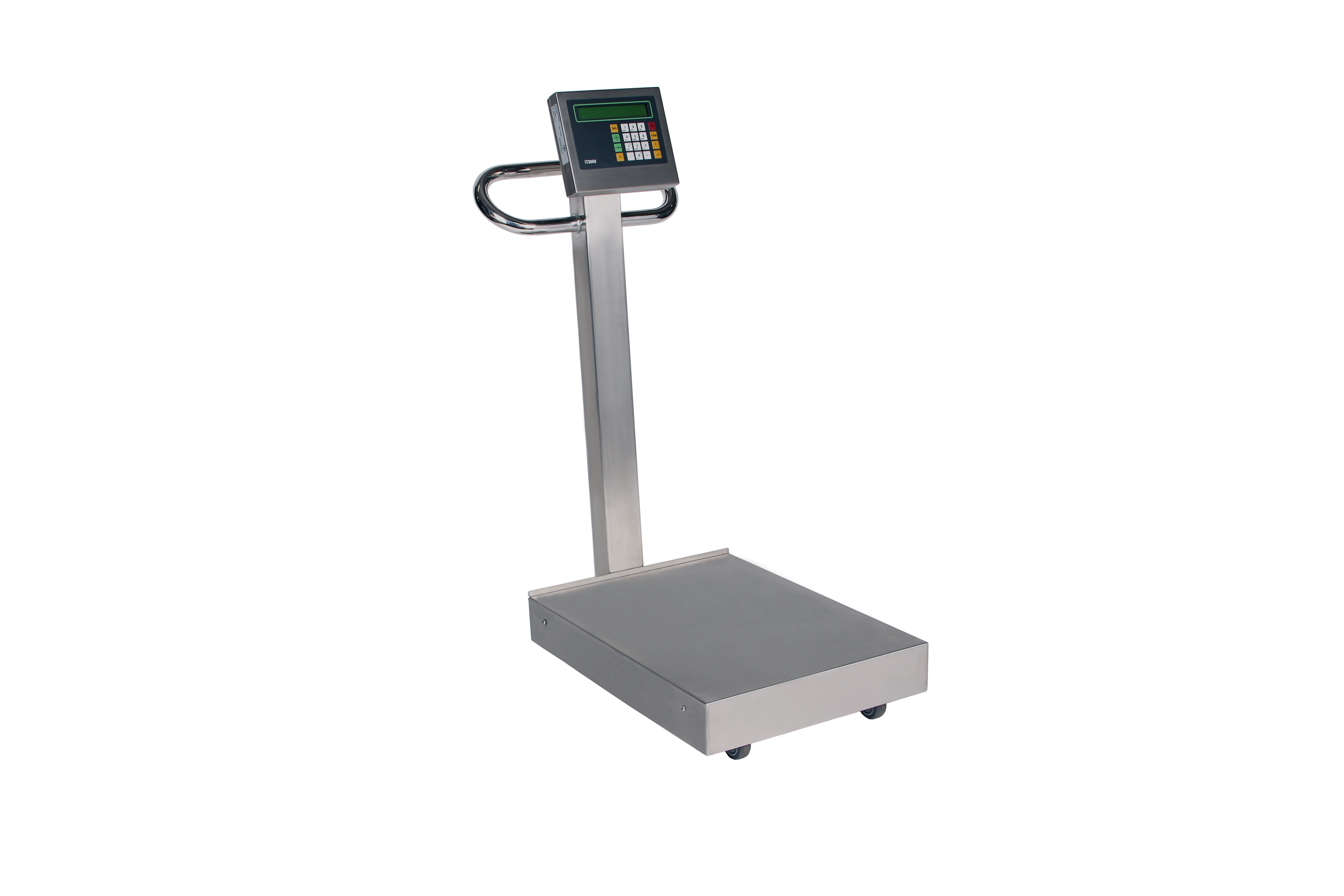

Hygienic mobile scale

Having a reliable and accurate weighing and measuring solution is absolutely essential, especially in t...

Gravimetric powder microdosing 2 - 100 g

Powders and granules are commonly dosed for the manufacturing of pharmaceuticals, ...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Economic tablet press

Successful pharmaceutical manufacturers know that high quality, reliable equipment is essential in orde...

Single rotary tablet press

Creating batches of consistent high quality pharmaceutical grade tablets from your powdered ingre...

Metal detection system for aluminum packages

The magneto reflection system is ideal for detection of metals in aluminium f...

Checkweigher for sachets and sticks

The checkweighers for multiple lanes have a 1.5 times faster response speed and 2 times...

Automatic tablet coater for lab scale

The ability to coat tablets in an even and controlled way is an important stage in th...

Lab scale single layer tablet press

Automated pressing of tablets saves time and improves quality. In R&D or laboratory...

Single layer tablet press

High performance tablet presses for the modern production environment need to be fast, accurate an...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

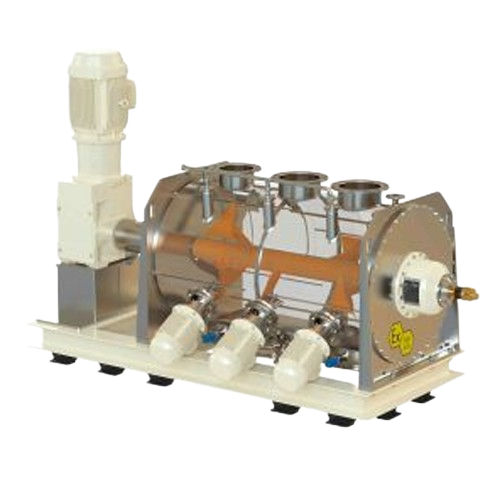

Horizontal pharmaceutical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliabilit...

Isolator centrifuge

For transferring highly active pharmaceutical ingredients (HAPI) without contamination from the isolator ...

Mobile pilot plant centrifuge

The system is perfectly suited for pilot plants as well as small-quantity productions in the f...

Vertical top discharge centrifuge

Discharge solids vertically upward through manual action, optionally using a filter bag o...

Vertical peeler centrifuge

A vertical peeler centrifuge is used to separate solids, usually to separate fine particles from ...

Vertical scraper centrifuges

Vertical Bottom discharge Centrifuges work discontinuously, discharging the solids to the botto...

Pusher centrifuge

Pusher centrifuges are continuously operating filter centrifuges and can have several basket stages dependi...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...