Vertical conical screw vacuum dryer

Achieve precise moisture control with ultra-vacuum batch drying, ideal for thermo-sensitive products. The conical screw design ensures efficient mixing and drying, perfectly integrating into processes requiring exact particle consistency and enhanced purity levels.

Dries and Mixes Thermo-Sensitive Materials Efficiently

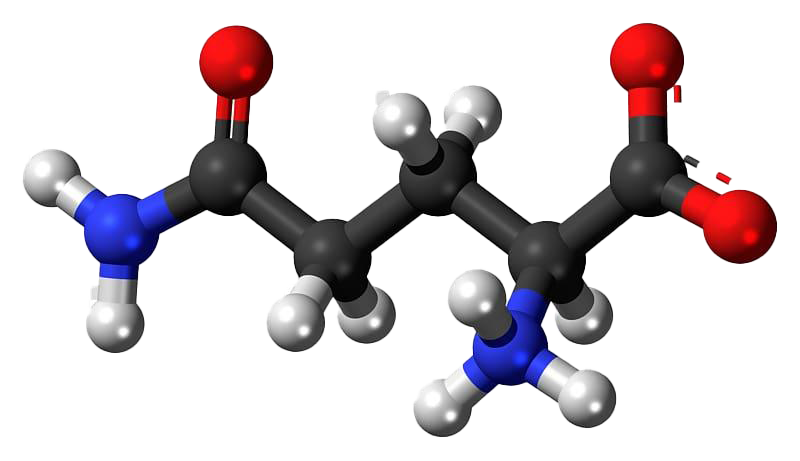

The Vertical Conical Screw Vacuum Dryer (MCV-S) from Bachiller is engineered to meet the demanding needs of fine chemical and pharmaceutical industries. Featuring a conical design and integrated screw mixing, it ensures gentle yet thorough drying of thermo-sensitive materials. The MCV-S operates under ultra-low vacuum conditions (<1 mbar), ideal for applications such as amino acids, antibiotics, and food additives. With capacities ranging from 30 to 10,000 liters, it offers flexible throughput for scaling operations. Designed in accordance with ASME VIII div.1 and EN-13445, the dryer meets strict cGMP and FDA requirements, ensuring compliance for sensitive pharmaceutical processes. Enhanced by options for ATEX certification and CIP/SIP systems, the dryer supports a seamless integration into existing production lines, reducing downtime with efficient cleaning protocols. Constructed with polished stainless steel, it provides high corrosion resistance and durability. Customizable features, including powder retention filters and lump-chopping choppers, offer tailored solutions for complex processing needs.

Benefits

- Ensures consistent drying quality with precise vacuum control.

- Minimizes energy usage via optimized heating surface design.

- Facilitates easy scaling and replication of batches.

- Enhances safety and cleanliness with sterile execution options.

- Reduces contamination risk through seamless integration with CIP/SIP systems.

- Applications

- Vitamins, Proteins, Antibiotics, Cosmetics, Crystals, Essences, Saccharine, Pigments, Catalysts, Sweeteners, Food, Chemicals, Pharmacy synthesis, Polymers, Stearates, Fine chemicals, Api’s, Caffeine, Ferments, Preservatives, Amino acids, Plastics, Resins, Ready mix, Pharmaceutical excipients, Pharmaceuticals, Vitamin complements, Colorants, Food additives, Veterinary, Aromas

- End products

- Lactic acid, Xylitol, Api granules, Folic acid, Ibuprofen, Melt-blown polypropylene, Polyethylene pellets, Sodium saccharin, Vanillin, Whey protein isolate, L-arginine, Cosmetic peptides, Chocolate flavors, Gelatin hydrosylate, Veterinary supplements, Beta-carotene, Industrial resins, Retinoids, Ethylvanillin, Riboflavin, Polypropylene powder, Lycopene, Omega-3 capsules, Aspartame, Food coloring agents

- Steps before

- Purification, Grinding, Emulsification, Fermentation

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing

- Input ingredients

- thermo-sensitive products, crystalline products, amorphous products, paste products

- Output ingredients

- amino acids, antibiotics, API’s, aromas, biotechnology products, caffeine, colorants, cosmetics, crystals, dental resins, diet food, essences and flavors, food additives, pharmaceutical excipients, pharmacy synthesis, preservatives, saccharine, sweeteners, veterinary products, vitamins, catalysts, pellets, pigments, plastics, polymers, resins, stearates, food preparations, lyophilized products, proteins, ready mix, vitamin complements

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Capacity

- 30–10, 000 L

- Vacuum level

- Less than 1 mbar

- Operating pressure

- Atmospheric

- Operation temperature

- Up to 200º C

- Surface finish

- Internally mirror polished Ra ≤ 0.6 µm

- Batch vs. continuous operation

- Batch operation

- Vacuum level control

- Less than 1 mbar

- Temperature range

- Up to 200º C

- Heating surface

- Maximized heating surface

- Automation level

- PLC-controlled / Automatic loading and unloading system

- Cleaning method

- Easy to clean and inspect / CIP/SIP systems

- Cleanability

- Easy to clean and inspect

- Corrosive resistance (e.g. acids)

- AISI-316-L material

- Density/particle size

- Suitable for crystalline, amorphous or paste products

- Biological compatibility

- cGMP, FDA validated

- Abrasion resistance

- Internally mirror polished Ra ≤ 0.6 µm

- Thermo-sensitivity

- Thermo-sensitive products

- Machine Footprint

- Compact design for space efficiency

- Tank Shape

- Fully conical vertical vessel

- Capacity

- 30L to 10, 000L

- Feed Discharge Method

- Automatic loading and unloading system available

- Internal Surface Finish

- Mirror polished Ra ≤ 0.6 µm

- External Finish

- Matte or Mirror

- Powder Retention Filter

- In the Vacuum Outlet

- Choppers

- For Breaking Lumps/Balls of Product

- CIP/SIP Systems

- Validated with Riboflavin Test

- Segregation Capability

- Into Clean Room/Service Room

- Automatic Loading/Unloading

- As an Option

- Sterile Execution

- As an Option