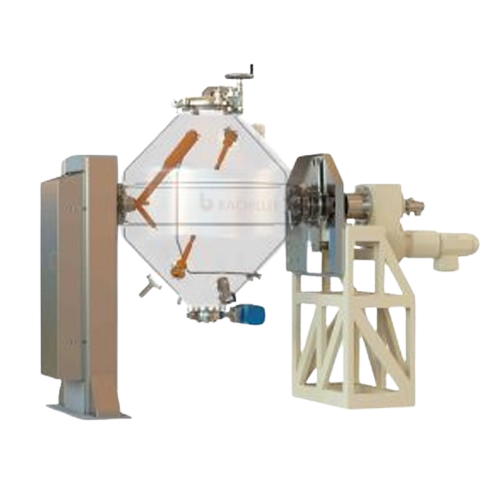

Double cone vacuum dryer for thermosensitive products

For precise drying of heat-sensitive powders, this double cone vacuum dryer optimizes moisture removal while preserving product integrity, making it ideal for sensitive applications like pharmaceuticals and cosmetics.

Dries and Rotates Thermo-Sensitive Products

The BICUUM (MBC-S) from Bachiller is a double cone vacuum dryer engineered for the ultra-vacuum drying of thermo-sensitive products across pharmaceuticals, fine chemicals, cosmetics, and food industries. It features a fully heated and insulated rotary drum under a strong vacuum, ensuring efficient moisture removal by keeping the product in constant contact with hot walls.

With capacities ranging from 30L to 30,000L, the BICUUM supports batch processes with vacuum levels below 1 mbar and operating temperatures up to 200º C. Its mechanical simplicity requires minimal maintenance while offering full tightness and low energy consumption due to a reduced product-to-power ratio. Integration options, including PLC control with automatic loading and unloading systems, enhance adaptability to existing production lines.

Constructed under ASME VIII div.1 and EN-13445 standards, it aligns with cGMP and FDA requirements, making it ideal for environments requiring high cleanliness and reproducibility. The mirrored internal finish (Ra ≤ 0.6 µm) facilitates easy cleaning and inspection, complemented by CIP/SIP systems. For industries demanding customized solutions, options include electro-polished surfaces, dust filters, lump-breaking choppers, and ATEX compliance for explosive environments.

Benefits

- Minimizes energy use with efficient heat transfer and vacuum operation.

- Enhances product quality by preserving thermo-sensitive materials during drying.

- Streamlines cleaning processes with integrated CIP/SIP systems.

- Ensures process consistency with reliable batch operation.

- Complies with stringent industry standards, supporting regulatory and quality requirements.

- Applications

- Food, Polymers, Fine chemicals, Lyophilized products, Antibiotics, Vitamin complements, Cosmetics, Metallic powders, Chemical catalysts, Aroma, Api's, Preservatives, Sweeteners, Resin, Pharmaceuticals

- End products

- Antibiotic capsules, Powdered meal replacements, Oily skin serums, Vitamin c supplements, Hypoallergenic eyeliners, Industrial-grade polymer pellets, Sticky resin binders, High-precision metallic powder additives, Dehydrated soup mixes, - cosmetic face powders, - performance-grade catalysts, Natural vanilla extract, Sugar substitutes, Mascara base, Bioactive apis, Lactose-free sweetener tablets, - food flavor enhancers, - pharmaceutical tablets, Waterproof adhesive resins, - preservative coatings, Lyophilized injections, Anti-aging creams, Aroma compounds

- Steps before

- Purification, Crystallization, Synthesis

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing

- Input ingredients

- moist products, crystalline products, amorphous thermo-sensitive products

- Output ingredients

- dried antibiotics, dried API’s, dried aroma, dried biotechnology products, dried caffeine, dried colorants, dried cosmetics, dried crystals, dried deontological resins, dried diet food, dried food additives, dried peptides, dried pharmaceutical excipients, dried pharmacy synthesis products, dried preservatives, dried saccharine, dried sweeteners, dried tables, dried vitamins, dried catalysts, dried metallic powders, dried pellets, dried plastics and pellets, dried polymers, dried food additives, dried flavors and aromas, dried lyophilized products, dried vitamin complements

- Market info

- Bachiller specializes in industrial engineered-to-order equipment, known for high-quality process equipment in the chemical, petrochemical, pharmaceutical, and food industries. They are recognized for their expertise in designing and manufacturing pressure vessels, reactors, and mixing equipment.

- Capacity

- 30L up to 30, 000L

- Vacuum Level

- Below 1 mbar

- Operation Temperature

- Up to 200º C

- Automation

- Hardware and software control

- Material

- AISI-316L

- Drum Size

- Fully heated and insulated

- Mirror Polish

- Internally Ra ≤ 0.6 µm

- Vacuum Intake

- Dust Filter

- CIP/SIP Systems

- Validated through Riboflavin test

- Sterile Execution

- On demand

- Execution

- ATEX 20/0 inner side

- Working mechanism

- Double cone rotary drum

- Vacuum level

- Below 1 mbar

- Batch operation

- Yes

- Automation level

- Manual / PLC / SCADA optional

- Cleaning method

- CIP/SIP systems available

- Temperature range

- Up to 200º C

- Insulation

- Fully heated and insulated drum

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Yes, suitable for thermosensitive products

- Density/particle size

- Wide range compatible

- CGMP Compliance

- Sanitary design cGMP

- FDA Compliance

- FDA validated

- ASME Certification

- ASME VIII div.1

- CE Marking

- CE stamping

- ATEX Certification

- ATEX 20/0 inner side

- EN Certification

- EN-13445

- AD-2000 Certification

- AD-2000

- Drum Shape

- Double Cone

- Drum Size (Capacity)

- 30L to 30, 000L

- Feed/Discharge Method

- Automatic loading and unloading systems

- Rotary Drum

- Yes

- Material

- AISI-316L

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / DCS

- Internal electro polishing

- Ra ≤ 0.2 µm

- Sampling valve

- Available on request

- Sterile execution

- Available on demand

- Automatic loading/unloading systems

- Optional

- ATEX execution

- Available on demand

- Condensation,vacuum,and heating systems

- Customizable

- Hardware and software control

- Optional