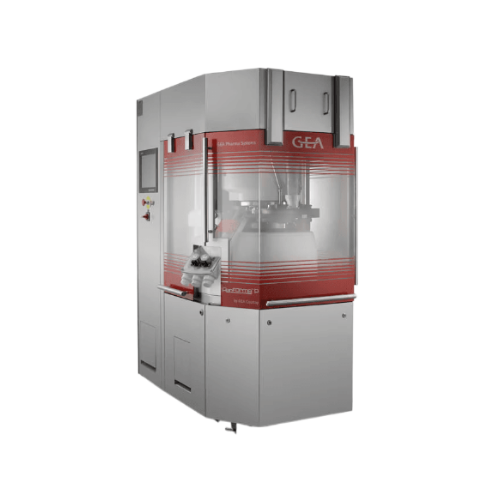

Rotary tablet press for pharmaceutical industries

Optimize your tablet production with swift format changeovers and bi-layer capability, enhancing your output efficiency and versatility without significant investment costs.

Compresses and Produces Single- and Bi-layer Tablets

The PERFORMA P Tablet Press from GEA offers a cost-effective solution for pharmaceutical and nutraceutical manufacturers by integrating the innovative Exchangeable Die Disc (EDD) technology. This feature significantly reduces downtime with fast and easy format changeovers, optimizing production efficiency. It supports single-layer and bi-layer tablet production, catering to a wide range of end-products such as paracetamol and bi-layer antihistamine tablets. With a maximum output capacity of up to 374,000 tablets per hour, the press ensures high-speed continuous operation. The PERFORMA P is PLC-controlled for seamless integration into existing production lines, maintaining precise control over tablet compression forces. Designed to handle powders and granules, it operates with variable compression forces up to 100 kN, ensuring quality and consistency. Compliant with stringent industry standards, its compact design includes integrated dust extraction systems and offers easy maintenance with a limited number of components needed for bi-layer production conversion.

Benefits

- Minimizes capital investment with cost-effective Exchangeable Die Disc technology.

- Enhances production versatility, supporting both single and bi-layer tablet manufacturing.

- Reduces downtime with rapid format changeovers, boosting operational efficiency.

- Supports high-speed, continuous operation with a maximum output of up to 374,000 tablets per hour.

- Ensures product quality with precise compression control and integrated dust extraction.

- Applications

- Nutraceuticals, Bi-layer tablets, Supplements, Pharmaceutical tablets

- End products

- Bi-layer caffeine tablets, Vitamin c tablets, Fish oil capsules, Multivitamin supplements, Bi-layer antihistamine tablets, Calcium supplements, Probiotic tablets, Paracetamol tablets

- Steps before

- Mixing, Granulation, Drying, Blending

- Steps after

- Coating, Quality Control, Packaging, Labeling

- Input ingredients

- pharmaceutical powder, nutraceutical powder, tablet formulation materials, bi-layer powder mixture

- Output ingredients

- single-layer tablets, bi-layer tablets, D tooling tablets, B tooling tablets, BB tooling tablets, BBS tooling tablets, A tooling tablets

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Max. tablet diameter [mm]

- 25, 16, 13, 11

- Punch body diameter [mm]

- 25, 19, 19, 19, 12

- Outside die diameter [mm]

- 38, 30, 16, 24, 22

- Number of stations

- 24, 30, 36, 39, 51

- Max. fill depth [mm]

- 20, 19

- Top punch penetration [mm]

- 1 to 4

- Max. pre-compression force [kN]

- 10, 2.5

- Max. compression force [kN]

- 100, 80

- Max. output capacity [tab/h]

- 374, 000, 143, 000

- Electrical requirements

- 3phase+PE – 380/400/415/460/480 V – 50Hz/60Hz

- Nominal consumption

- 6 kW

- Power installed

- 11.9 kVA

- Compressed air requirements

- Clean, dry / 7-8 bar / 500l/m

- Dust extraction requirements

- 150 m³/h at 15 mbar

- Machine dimensions,weight

- W = 1, 030 mm x D = 1, 555 mm x H = 2, 170 m – 2, 500 kg

- Working mechanism

- Rotary tablet press

- Format changeover

- Fast and easy with Exchangeable Die Disc

- Bi-layer production capability

- Yes, with optional kit

- Automation level

- Manual / PLC

- Accessibility

- Unmatched accessibility of compression area

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- W = 1.030 mm x D = 1.555 mm x H = 2.170 mm

- Machine weight

- 2, 500 kg

- Changeover time

- Fast and easy with Exchangeable Die Disc (EDD)

- Control panel type

- Operator-friendly, intuitive

- Compression setup

- Bi-layer capability, single-layer

- Modular design

- Exchangeable Die Disc and bi-layer kit

- Integration possibilities

- SCADA systems, remote monitoring