Spherical vacuum dryer for Apis and fine chemicals

Achieve precise moisture control and efficient drying for APIs and fine chemicals with our versatile spherical vacuum dryer, engineered for optimized batch processes and seamless integration into your production line.

Dries, Mixes, and Discharges Powder Formulations

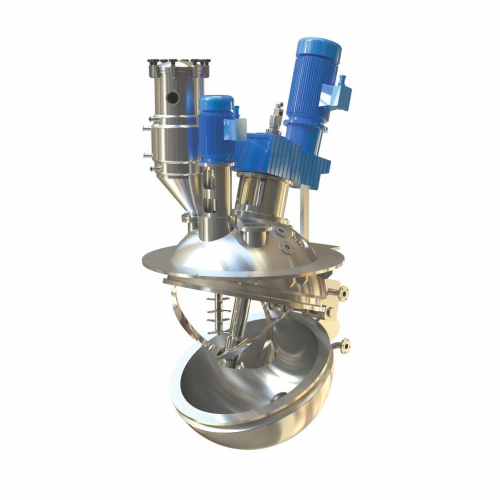

The MAVASPHERE® from GMM Pfaudler is a spherical vacuum dryer designed for pharmaceutical and fine chemical manufacturing, ensuring exceptional drying performance and efficient operations. It features an eccentrically mounted agitator that provides uniform mixing and drying, with minimal product hold-up for easy cleaning and validation. Suitable for Active Pharmaceutical Ingredients (APIs) and chemicals such as paracetamol and aspirin, it operates with various filling capacities and a good turndown ratio.

This multi-purpose dryer integrates seamlessly into your production line with temperature-controlled automation units and vacuum systems for solvent recovery. Made from Stainless Steel, Hastelloy, and special alloys, it offers superior corrosion resistance, meeting cGMP and FDA guidelines. The optional dry9000® shaft sealing system and chopper for effective lump breaking enhance its versatility. A compact design reduces the footprint, and its CIP system supports contamination-free cleaning, minimizing downtime and ensuring compliance with industry standards.

Benefits

- Enhances product quality with uniform drying and mixing capabilities.

- Reduces cleaning time through minimal product hold-up and CIP system.

- Increases operational efficiency by recovering solvents during the drying process.

- Durable in harsh chemical environments with corrosion-resistant material options.

- Complies with cGMP and FDA standards, ensuring regulatory adherence.

- Applications

- Chemicals, Active pharmaceutical ingredients, Fine chemicals, Powder formulations, Pharmaceuticals

- End products

- Paracetamol, Aspirin, Vitamin c, Caffeine, Benzoic acid, Penicillin, Ibuprofen, Erythromycin, Calcium carbonate powder, Citric acid

- Steps before

- Filtration, Solvent Recovery, Membrane Separation

- Steps after

- Packaging, Sterilization

- Input ingredients

- Active Pharmaceutical Ingredients (API's), Fine Chemicals

- Output ingredients

- Dried Active Pharmaceutical Ingredients, Dried Fine Chemicals, Lump-free products

- Market info

- GMM Pfaudler is known for manufacturing glass-lined equipment, reactors, and engineered-to-order (ETO) solutions for the chemical, pharmaceutical, and allied industries, recognized for their innovation, quality, and global presence.

- Compliance

- cGMP, FDA

- Filling Capacities

- Wide range

- Turndown Ratio

- Good

- Discharge Method

- Spherical disc valve

- Clearance

- Minimal between vessel wall and agitator

- Construction Materials

- Stainless Steel, Hastelloy, Special Alloys

- Shaft Sealing System

- Interseal Dry9000®, Gas lubricated double mechanical seal

- Agitator Type

- Hollow heated, rotating 3-blade

- Automation Systems

- Temperature control units, Vacuum and solvent recovery units, Powder handling / Pack-off systems

- Accessories

- Lump Breaker, Dust Filter, Sampling System

- Working Mechanism

- Vacuum drying

- Integrated Steps

- Drying and mixing

- Mixing Method

- Agitator with minimal clearance

- Batch Operation

- Batch process

- Cleaning Method

- Easy cleaning and validation

- Discharge Method

- Bottom discharge with spherical disc valve

- Automation Level

- Available with automation systems

- Energy Efficiency

- Compact system with lower footprint

- Corrosive resistance

- Stainless Steel, Hastelloy, Special Alloys

- Cleanability

- Minimal product hold-up

- Compact footprint

- Lower footprint

- Discharge method

- Spherical disc valve at lowest point

- Machine shape

- Spherical

- Agitator type

- Eccentrically top mounted with heated, rotating 3-blade

- Material of construction

- Stainless Steel, Hastelloy, Special Alloys

- Shaft Sealing Design

- Interseal Dry9000® shaft sealing system

- Agitator

- Hollow heated, rotating 3-blade

- Gas Lubricated Double Mechanical Seal

- Installed outside of the product zone

- Bottom Discharge

- Spherical disc valve for quick opening

- Standard Accessories

- Lump Breaker, Dust Filter, Sampling System

- Optional Accessories

- Vessel flange with bayonet type, quick-closing design

- Automation Systems

- Temperature control units, Vacuum and solvent recovery units, Powder handling / Pack-off systems