High speed strip packaging for tablets and capsules

Ensure precise packaging of pharmaceutical tablets and capsules with high-speed efficiency, optimizing your production line with integrated sealing, pouching, and feeding processes.

Seals and Packages Tablets and Capsules

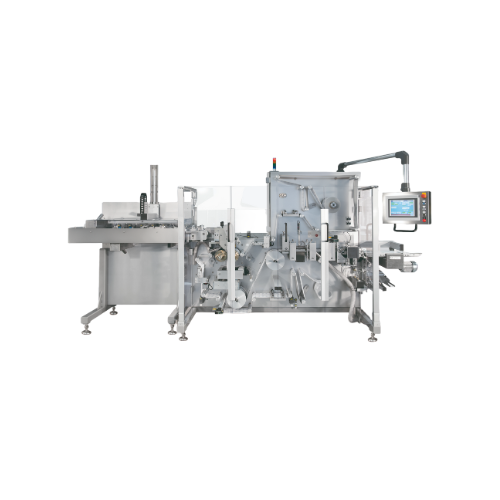

The 5000EH from Tecnicam is a high-speed strip packaging machine designed for pharmaceutical manufacturers seeking efficient and precise packaging solutions. Featuring vertical sealing with horizontal exit, it is ideal for tablets, capsules, and effervescent tablets, ensuring secure packaging via four-side sealing. With a processing speed of up to 300 cycles per minute, it accommodates various products by adjusting foil width. The 5000EH uses heat-sealable films like cellophane and aluminum, delivering airtight packaging suitable for pharmaceuticals like paracetamol tablets and multivitamin capsules. Integration is seamless with continuous production lines, thanks to its compact design and cantilever structure, allowing easy maintenance and cleaning. It meets GMP regulations and offers customization options, including longitudinal perforation, coding via ink-jet or flexo printers, and interfaces for upstream and downstream machines.

Benefits

- Increases packaging speed with up to 300 cycles per minute for high-output demands.

- Ensures product integrity with airtight four-side sealing, crucial for pharmaceutical compliance.

- Facilitates seamless integration into existing lines with horizontal exit design.

- Simplifies maintenance and reduces downtime with easy access due to its cantilever structure.

- Complies with GMP requirements, ensuring regulatory adherence for pharmaceutical manufacturing.

- Applications

- Capsules, Pharmaceutical tablets, Effervescent tablets

- End products

- Multivitamin capsules, Ibuprofen capsules, Vitamin c effervescent tablets, Aspirin tablets, Paracetamol tablets

- Steps before

- Tablet Pressing, Capsule Filling, Effervescent Tablet Formulation

- Steps after

- Grouping Outfeed, Outfeed Conveyor, Packaging, Coding, Print Mark Centering

- Input ingredients

- tablets, capsules, effervescent tablets, heat-sealable films, cellophane, aluminum, coated paper, laminates

- Output ingredients

- sealed pouches, packaged products, airtight packaging

- Market info

- CAM Packaging is known for its expertise in designing and manufacturing advanced packaging machinery tailored to client specifications, with a strong reputation for reliability and innovation in the engineered-to-order equipment market.

- Machine Speed

- up to 300 cycles/min

- Film Compatibility

- Cellophane, aluminum, coated paper, laminates

- Sealing Method

- Four-side sealing

- Material Feeding

- Two reels by a film unwinding unit

- Temperature Control

- Separate temperature controls for the sealing rollers

- Product Orientation

- Synchronized with the sealing rollers

- Machine Design

- Cantilever structure

- Maintenance,Cleaning

- Easy access and compact design

- Foil Edge Trimming

- System available

- Optional Devices

- Longitudinal and cross perforation, coding, print mark centering

- Installation Requirement

- Low ceiling required

- Output

- Horizontal exit

- Compliance

- GMP Regulations

- Machine speed

- Up to 300 cycles/min

- Sealing type

- Four-side sealing/pouching

- Product type

- Tablets, capsules, effervescent tablets

- Film compatibility

- Heat-sealable films (excluding pure polyethylene)

- Format changeover

- Easy and quick change over

- Machine accessibility

- Complete, easy accessibility

- Temperature and pressure control

- Easy setting unit

- Exit type

- Horizontal exit

- Line integration

- Interfacing with up or downstream machines

- Cleaning method

- Easy maintenance and cleaning operations

- Standard components

- Longitudinal and cross perforation, hole punching station, coding, etc.

- Heat-sealable films compatibility

- Cellophane, aluminum, coated paper, laminates

- Packing material compatibility

- Excludes pure polyethylene

- Machine footprint

- Compact

- Feed method

- Film unwinding unit

- Discharge method

- Horizontal exit

- Structure

- Cantilever

- Integration possibilities

- Line integration and interfacing with upstream or downstream machines

- Custom requirements

- Upon request

- Changeover parts

- Easy and quick change over

- Temperature and pressure setting

- Easy setting unit