Electronic counting and filling system for vials

Efficiently streamline the packaging of solid dosage forms with a cutting-edge system that combines precise counting, filling, and inspection capabilities, ensuring product integrity and reducing waste in high-speed, continuous operations.

Accurately Counts and Packages Tablets and Capsules

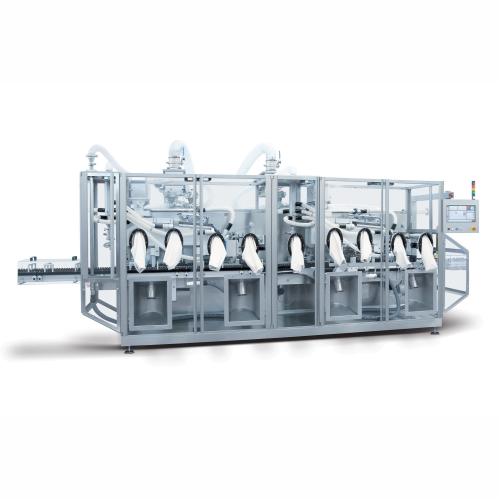

The ELECTRA Electronic Counting Machine from the Marchesini Group is designed to streamline the counting and packaging process for solid dosage forms in pharmaceutical and nutraceutical industries. This equipment combines a volumetric filling system with an electronic control system, ensuring precise counting and product integrity through advanced sensor technology and a camera vision system. Capable of performing multiple filling operations, ELECTRA supports high-speed, continuous production environments with its compact automatic rejection and reliable vial transport systems. The machine is managed via a PC Siemens interface featuring an industrial touch-screen monitor for user-friendly operation. It can be customized with several accessories to meet specific production requirements. Its design supports integration into existing production lines, enhancing overall efficiency and maintaining high standards of quality and compliance with industry regulations. The machine’s construction includes robust materials to ensure durability and ease of maintenance, meeting stringent GMP and FDA standards.

Benefits

- Enhances accuracy and reduces product loss with precise electronic counting and filling.

- Increases operational efficiency through high-speed, continuous production capability.

- Minimizes downtime with a compact automatic rejection system for quick error correction.

- Supports compliance with GMP and FDA standards, ensuring product safety and quality.

- Offers flexibility with customizable accessories to adapt to specific production needs.

- Applications

- Supplements, Vitamins, Pharmaceutical tablets, Nutraceuticals, Solid dosage forms

- End products

- Magnesium tablets, Fish oil soft gels, Vitamin d3 capsules, Herbal extract capsules, Multivitamin supplements, Probiotic tablets, Calcium chewable tablets, Vitamin c capsules, Aspirin tablets, Glucosamine supplements

- Steps before

- Purification, Inspection for Glass Containers, Air Cleaner and Blowing, Sorting

- Steps after

- Packing, Labeling, Cartoning, Palletizing

- Input ingredients

- Output ingredients

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Filling Method

- Volumetric / Electronic Control

- Automation

- PC Siemens Machine Management

- Operator Interface

- Industrial PC with Touch-screen Monitor

- Rejection System

- Compact Automatic

- Camera Vision System

- Product Integrity Check

- Sensors

- Counting and Integrity Check

- Feeding System

- Very Reliable

- Working mechanism

- Volumetric filling with electronic control

- Integrated steps

- Automatic rejection, vial transport

- Batch vs. continuous operation

- Batch operation with multiple filling options

- Automation level

- PLC-controlled with touch-screen interface

- Camera vision system

- Product integrity check

- Compact design

- Yes

- Filling flexibility

- Multiple accessories based on customer needs

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Compact design

- Discharge method

- Automatic rejection system

- Control panel type

- Industrial PC with touch-screen monitor

- Vial transport system

- Very reliable feeding system

- Control panel type

- Industrial PC with touch-screen monitor

- Integration possibilities

- Several accessories installation

- Feeding system

- Very reliable feeding system

- Rejection system

- Compact automatic rejection system