Evaporative crystallizers for chemical processing

Optimize your crystallization process with state-of-the-art evaporative technology designed to enhance product purity and efficiency through precise precipitation and volume reduction of diverse compounds.

Precipitates and Purifies Crystalline Solids

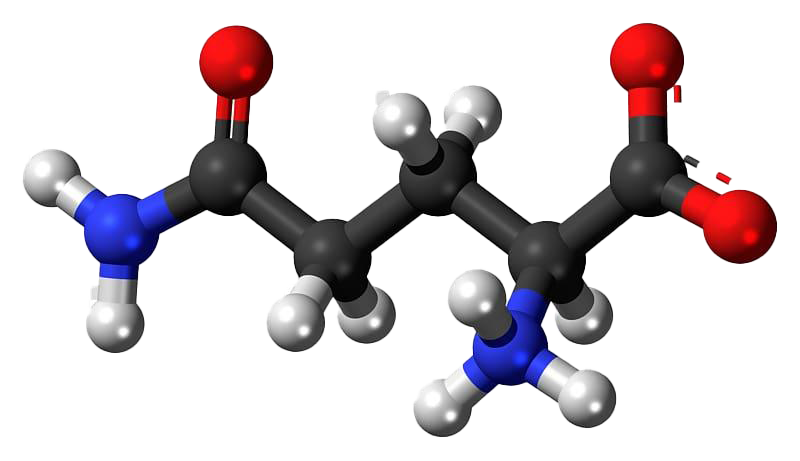

The Dedert Forced Circulation Crystallizer is designed for chemical producers, pharmaceutical manufacturers, and food ingredient producers seeking efficient and reliable crystallization solutions. This system operates on a forced circulation mechanism where a continuous slurry of precipitated solids suspends in liquid, facilitating crystal growth and volumetric reduction. It supports applications ranging from the precipitation of amino acids, such as Threonine and Glucosamine, to the purification of electrolytes and vitamin supplements. Capable of integrating seamlessly with existing production lines, it maintains high purity and cost efficiency. The crystallizer offers skid-mounted configurations for compact on-site installation, complete with heat exchangers and motors for customized operation. The setup is PLC-controlled and compatible with a variety of energy sources, ensuring optimized evaporation processes with reduced energy consumption. Constructed with durable materials to resist corrosion, it is available in stainless steel variants to meet stringent chemical compatibility needs. Dedert’s engineering support offers flexibility in customization according to specific process requirements, ensuring comprehensive compliance with industry standards.

Benefits

- Minimizes operational costs by reducing energy consumption through efficient evaporation.

- Enhances product purity and quality with precise precipitation and purification processes.

- Streamlines production with continuous, skid-mounted operation for quick and easy integration.

- Offers flexibility for various applications with customizable configurations and material options.

- Ensures compliance with industry standards in chemical and pharmaceutical manufacturing.

- Applications

- Sodium chloride, Vitamin c, Potassium citrate, Sodium sulfate, Gluconic acid, Cyclodextrin, Potassium carbonate, Food, Magnesium lactate, Amino acids, Glucosamine, Monosodium glutamate, Chemical, Citric acid, Ammonium sulfate, Threonine, Itaconic acid, Pollution control operations, Utility, Sodium citrate, Dextrose, Pharmaceutical

- End products

- Potassium salt substitutes, Threonine feed additives, Table salt, Citric acid for beverages, Magnesium supplements, Glucosamine tablets, Itaconic acid for resins, Baking powder, Vitamin supplements, Cyclodextrin for pharmaceuticals, Msg seasoning, Electrolyte supplements, Food grade dextrose, Sodium citrate for beverages

- Steps before

- Evaporation, Filtration, Mixing

- Steps after

- Centrifugation, Drying, Packaging

- Input ingredients

- process solutions, waste solutions

- Output ingredients

- crystalline solids, amino acids, ammonium sulfate, citric acid, cyclodextrin, dextrose, gluconic acid, glucosamine, itaconic acid, magnesium lactate, monosodium glutamate, potassium carbonate, potassium citrate, sodium chloride, sodium citrate, sodium sulfate, threonine, vitamin C

- Market info

- Dedert is known for its expertise in designing and supplying advanced drying and evaporation technologies, serving the chemical, food, and other processing industries with innovative and efficient engineered-to-order solutions.

- Operation mode

- Forced Circulation

- Skid Mounted Features

- Pre-assembled, Turn-key options

- Heating method

- Condensation on tube exteriors

- Feed type

- Liquid with suspended solids

- Heat exchangers

- Included in skid

- Pumps and motors

- Included in skid

- Instrumentation and control

- Included in skid

- 3-D Modelling

- Available for equipment, piping, steel

- Optional code stamp

- Available for pressure vessels

- Working mechanism

- Forced circulation with heat-exchange tubes

- Batch vs. continuous operation

- Continuous

- Energy source compatibility

- Compatible with evaporator energy sources

- Skid mounted option

- Basic skid to full Turn-Key solution

- Automation level

- Instrumentation and control valves integrated

- CIP/SIP

- Not specified

- Cleaning method

- Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed/discharge method

- Forced circulation

- Skid-mounted design

- Pre-assembled

- Heat-exchange components

- Tubes within chest

- Structural materials

- Steel

- Control panel type

- HMI / PLC

- Integration possibilities

- 3-D Modelling

- System assembly options

- Skid Mounted / Turn-Key Solution

- Materials included

- Heat exchangers / Pumps and motors

- Optional features

- Code stamp for pressure vessels