High speed blister packaging for pharmaceutical industry

Ensure precision and speed in pharmaceutical packaging with a high-speed blister packer, integrating seamlessly into your production line to enhance workflow efficiency and product integrity.

Forms, Seals, and Cuts Pharmaceutical Blisters

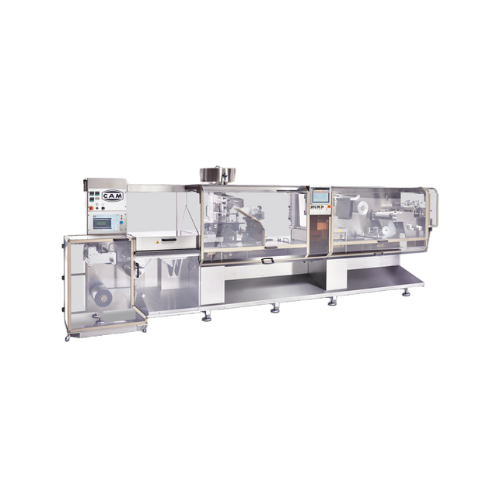

The MK33 blister packaging machine from CAM simplifies high-speed pharmaceutical blister packaging by addressing key production challenges faced by manufacturers. Engineered in accordance with GMP standards, it offers a streamlined web path and clear product handling areas for easy line clearance and maintenance. The machine’s flexibility accommodates a wide range of forming materials, like PVC and PVDC, paired with various lidding materials, maximizing adaptability for different tablet, capsule, and pill formats. Designed for continuous operation, its reliable mechanical system uses 4 grippers to align blisters precisely during sealing, ensuring optimal throughput. With the capacity to produce up to 12 blisters per stroke, it integrates seamlessly with downstream equipment, enhancing the overall efficiency of your packaging line. Suitable for industries such as pharmaceuticals and biotech, the MK33 ensures compliance with stringent quality standards while supporting swift format changeovers.

Benefits

- Enhances operational efficiency with continuous, high-speed blister production.

- Supports diverse product requirements with flexible material compatibility.

- Minimizes line clearance time with straightforward cleaning and maintenance.

- Ensures precise sealing and product integrity through reliable mechanical alignment.

- Facilitates quick product changeovers, optimizing time and resource management.

- Applications

- Vitamins, Supplements, Pharmaceutical tablets, Nutraceuticals, Pills, Capsules, Pharmaceuticals

- End products

- Omega-3 fish oil capsules, Herbal supplement capsules, Vitamin c tablets, Iron deficiency pills, Gel capsules, Immune support capsules, Acetaminophen tablets, Multivitamin supplements, Pain relief tablets, Probiotic pills

- Steps before

- Material Preparation, Web Forming, Feeder Configuration

- Steps after

- Blister Sealing, Cutting, Blister Packing, Conveying, Downstream Equipment Integration

- Input ingredients

- PVC, PP, PVC-PVDC, PVC-PE-PVDC, ACLAR, PETG, ALLI-PE, ALU-PP, ALUMINIUM, ALUMINIUM-PAPER, ALUMINIUM-PAPER-MYLAR, ALUMINIUM-PE, POLYPROPYLENE, hard gelatine capsules, soft gelatine capsules, round sugar coated pills, oval sugar coated pills, coated tablets, uncoated tablets

- Output ingredients

- blister packs

- Market info

- CAM Packaging is known for its expertise in designing and manufacturing advanced packaging machinery tailored to client specifications, with a strong reputation for reliability and innovation in the engineered-to-order equipment market.

- Speed

- Up to 12 blisters/stroke

- Motion Type

- Intermittent

- Web Transfer Method

- 4 mechanical grippers

- Forming Material Compatibility

- PVC, PP, PVC-PVDC, PVC-PE-PVDC, ACLAR, PETG, ALLI-PE, ALU-PP

- Lidding Material Compatibility

- Aluminium, Aluminium-Paper, Aluminium-Paper-Mylar, Aluminium-PE, Polypropylene

- Product Types

- Hard or soft gelatin capsules, round and oval sugar-coated pills, coated or uncoated tablets

- Automation

- Quick release devices for format change-over

- Sealing Type

- Plate sealing

- Format Change-Over

- Quick release devices

- Working Mechanism

- Intermittent Motion

- Product Handling

- Separated from Mechanical Movements

- Changeover Simplicity

- Quick Release Devices

- Batch vs. Inline Operation

- Batch

- Feeding Method

- Continuous Cycle Feeding

- Material Handling Flexibility

- Multiple Material Types

- Cleaning Method

- Manual Ease of Cleaning

- Automation Level

- Mechanical Crank and Link Device

- Forming materials

- PVC, PP, PVC- PVDC, PVC-PE-PVDC, ACLAR, PETG, ALLI-PE, ALU-PP

- Lidding materials

- ALUMINIUM, ALUMINIUM-PAPER, ALUMINIUM-PAPER-MYLAR, ALUMINIUM-PE, POLYPROPYLENE

- Product Types

- Hard or soft gelatin capsules, sugar coated pills, coated or uncoated tablets

- Flexibility,Versatility

- Wide range of forming and lidding materials

- Footprint

- Compact

- Machine Layout

- Linear

- Discharge Method

- Conveyor

- Web Transfer Method

- Mechanical Grippers

- Control panel type

- HMI with touchscreen

- Integration possibilities

- Integration with downstream equipment

- Changeover adaptability

- Quick release devices

- Material handling compatibility

- Handles multiple forming materials such as PVC, PP, ALU-PP

- Feeder type

- Wide range of feeders for various product types