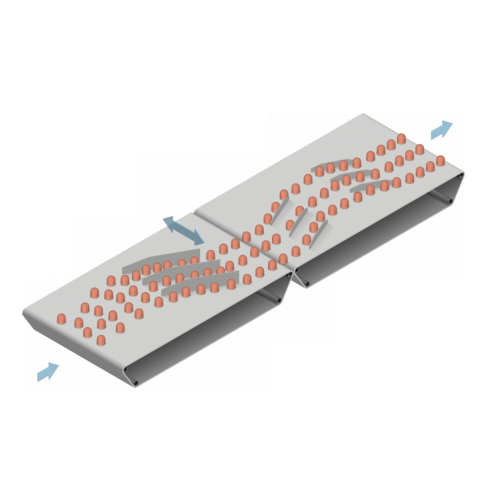

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration of lane arrangement systems that streamline product flow and enhance packing precision.

Organizes and Distributes Solid Products for Packaging

The Lane Arrangement and Distribution System from Theegarten-Pactec delicately orchestrates the flow of solid products, precision-aligning them into designated lanes to optimize packaging efficiency. Especially beneficial for food and confectionery manufacturers, the system transforms chaotic product streams into orderly queues, paving the way for seamless downstream processing. This system reliably serves a variety of products, from bouillon cubes to chocolate fudge squares, showcasing its versatility across numerous applications. Resiliently built, it includes pneumatically controlled switches for accurate product distribution, coupled with a three-phase motor and integrated frequency controller to ensure consistent operation. Designed for ease of maintenance, it features removable conveyor supports and quick tensioning devices, making cleaning straightforward and reducing downtime. It integrates effortlessly into production lines, enhancing throughput while maintaining sanitation and efficiency across high-speed, fully automated operations.

Benefits

- Enhances production efficiency by organizing product flow into precise lanes, minimizing bottlenecks.

- Lowers maintenance costs through easy-access cleaning features and quick tensioning mechanisms.

- Supports high-speed operations with integrated frequency control, optimizing throughput.

- Adaptable to diverse product types, improving flexibility across multiple production lines.

- Seamlessly integrates into existing systems, reducing installation time and cost.

- Applications

- Chewy sweets, Soft caramels, Bouillon cubes, Effervescent tablets, Hard candies, Eclairs, Fudge, Chocolate products, Toffee, Cereals, Jelly products, Bubble gum products, Dishwasher tablets, Preformed products, Krówki, Chewing gum

- End products

- Dark chocolates, Traditional toffee, Butterscotch hard candies, Cornflakes, Granola bars, Beef bouillon cubes, Milk chocolates, Chicken bouillon cubes, Peppermint chewing gum, Bubble gum balls, Caramel-filled chocolates, Lemon-scented dishwasher tablets, Coffee-flavored eclairs, Vitamin c effervescent tablets, Chocolate fudge squares, Soft caramel chews, Fruit-flavored jelly beans, Polish krówki candy

- Steps before

- product processing, product handling, deflecting, conveyor loading

- Steps after

- product distribution, packaging, automatic wrapping, lane arrangement

- Input ingredients

- chocolate products, hard caramels, jelly products, preformed products, chocolate balls, chocolate eggs, soft caramels, chewy sweets, effervescent tablets, bouillon cubes, cereals, chewing gum, bubble gum, toffee, fudge, dishwasher tablets, eclairs

- Output ingredients

- packaged chocolate products, packaged hard caramels, packaged jelly products, packaged preformed products, packaged chocolate balls, packaged chocolate eggs, packaged soft caramels, packaged chewy sweets, packaged effervescent tablets, packaged bouillon cubes, packaged cereals, packaged chewing gum, packaged bubble gum, packaged toffee, packaged fudge, packaged dishwasher tablets, packaged eclairs

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Line arrangement

- Continuous

- Conveyor motor

- Three-phase motor

- Speed control

- Frequency controller

- Web tracking control

- Pneumatic

- Conveyor cleaning access

- Removable support plates

- Conveyor maintenance

- Quick tensioning devices

- Waste management

- Sliding waste trays

- Product transfer shafts

- 10 mm diameter

- Automation

- Fully automatic distribution

- Transfer station type

- Cross transfer stations

- Lane division

- Deflectors

- Product flow control

- Pneumatically operated switches

- Conveyor system type

- Three-phase motor driven

- Automation level

- Frequency controller integrated

- Product handling

- Fixed or swivelling guides

- Quick maintenance

- Quick tensioning devices

- Cleaning access

- Removable conveyor support plates

- Waste management

- Underneath sliding waste trays

- Product transfer smoothness

- 10 mm return shafts

- Cleanability

- Removable conveyor support plates

- Abrasion resistance

- Conveyor belts with quick tensioning devices

- Density/particle size

- Suitable for a variety of product types

- Discharge method

- Lane arrangement

- Lane arrangement

- Continuous or discrete

- Guide type

- Fixed or swivelling

- Motor type

- Three-phase frequency controlled

- Web tracking control

- Pneumatic

- Conveyor access

- Removable support plates

- Conveyor tensioning

- Quick tensioning devices