Blister packaging solution for small-medium batches

Achieve unparalleled versatility and efficiency in blister packaging with a compact solution designed for just-in-time production of diverse solid dose forms, ensuring seamless integration and high-speed operations.

Packages Tablets and Capsules into Blisters

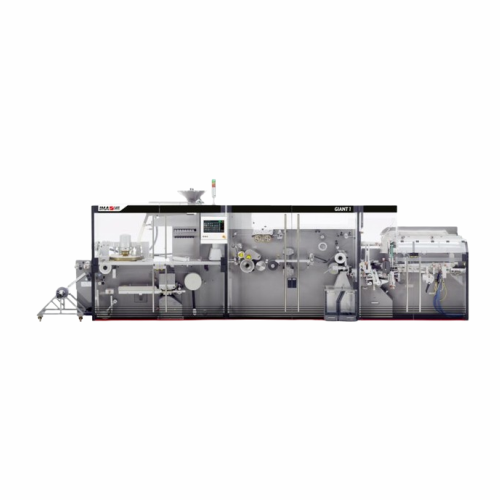

The GIANT1 Series from IMA Group is a versatile blister packaging solution designed to meet the demanding needs of pharmaceutical and biotech companies. Known for its ability to manage a wide range of tablet and capsule shapes, it employs innovative servomotor technology and the patented Sombrero universal feeder to ensure continuous production without interruptions from product irregularities. Capable of packaging up to 400 blisters per minute, it facilitates just-in-time production of small to medium batches. The GIANT1 Series is seamlessly integrated with cartoner systems via positive blister transfer, enabling smooth downstream operations such as carton transfer, product insertion, and carton closing. The machine’s energy efficiency is enhanced by its sustainable design, using minimal energy and compatible with recyclable packaging materials. Constructed to meet GMP standards, this system offers complete accessibility for maintenance and swift format changeovers, ensuring minimal downtime while maintaining high output quality.

Benefits

- Ensures continuous production with the Sombrero universal feeder, unaffected by tablet inconsistencies.

- Minimizes energy consumption while supporting green initiatives through compatibility with recyclable materials.

- Streamlines operations with quick, reproducible format changeovers, reducing production downtime.

- Enhances product handling with seamless integration into existing packaging lines.

- Meets stringent GMP standards, ensuring consistency and quality in pharmaceutical packaging.

- Applications

- Solid dose solutions, Vitamins, Supplements, Pharmaceutical tablets, Nutraceuticals

- End products

- Vitamin b12 capsules, Ibuprofen tablets, Omega-3 fish oil capsules, Vitamin c tablets, Antioxidant supplements, Probiotic supplements, Multivitamin supplements, Herbal supplements, Paracetamol tablets, Calcium and vitamin d3 tablets

- Steps before

- Solid dose preparation, Tablet forming, Capsule filling

- Steps after

- Cartoning, Wallet packing, Flow packing, End-of-line processing

- Input ingredients

- solid pharmaceutical shapes, alu-alu blister foil, recyclable materials, compostable materials

- Output ingredients

- blisters, cartons

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Output

- Up to 400 blisters/minute

- Production Output

- Up to 350 cartons/minute

- Blister Dimensions - Width

- 30-90 mm

- Blister Dimensions - Length

- 60-145 mm

- Blister Dimensions - Depth/Height

- 3-12 mm

- Carton Dimensions - Width

- 35-97 mm

- Carton Dimensions - Length

- 65-154 mm

- Carton Dimensions - Depth/Height

- 12-106 mm

- Containment Application

- Designed For

- Blister Recovery

- IMA patented magazine

- Blister Pocket

- No limitation on alu-alu

- Format Changeover

- Quick and reproducible

- Feeding System

- IMA patented Sombrero universal feeder

- Automation

- Integrated track, trace module

- Connectivity

- Easily connects to downstream packaging machines

- Energy Consumption

- Reduced to minimum

- Material Compatibility

- Recyclable/compostable materials

- Automation level

- PLC / SCADA

- Changeover time

- Quick and reproducible

- Batch vs. continuous operation

- Batch

- Energy efficiency

- Reduced energy consumption

- Integrated steps

- Blistering and cartoning

- Workflow design

- Linear

- Machine footprint

- Extremely compact line

- Blister dimensions

- 30-90 mm (Width), 60-145 mm (Length), 3-12 mm (Depth/Height)

- Carton dimensions

- 35-97 mm (Width), 65-154 mm (Length), 12-106 mm (Depth/Height)

- Feeder type

- IMA patented Sombrero universal feeder

- Blister feeding system

- IMA patented blister recovery magazine

- Design

- Linear workflow with full accessibility

- Workflow

- Linear

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Compatible with cartoner, wallet packer, flowpacker, or end-of-line machines

- SOMBRERO Feeder

- Versatile and efficient universal feeder

- Format changeover

- Quick and reproducible guided

- Connectivity

- Easily connectable to downstream packaging machines

- Energy efficiency

- Reduced energy consumption

- Material compatibility

- Recyclable/compostable materials