Counting and capping solution for tablets and capsules

Streamline your tablet and capsule production with a high-speed solution designed to ensure precise counts, secure capping, and seamless integration into your packaging line, minimizing downtime and maximizing output.

Fills, Caps, and Counts Tablets and Capsules

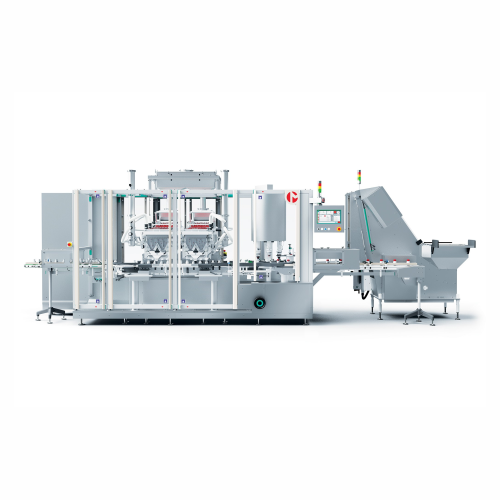

The COMPACT-24 from Marchesini Group is an innovative monoblock machine tailored for the high-speed filling and capping of pharmaceutical tablets and nutraceutical capsules. It features a revolutionary magnetic movement transport system, offering autonomous handling of each bottle to optimize speed, positioning, and format changes. The dual 12-channel counting groups allow precise counting and filling, reaching speeds of up to 150 bottles per minute. Designed for seamless integration, the COMPACT-24 supports continuous operation with a focus on reducing downtime and ensuring accuracy through comprehensive inspection systems, including 100% weight control and 2D/3D camera verification. This machine is ideal for pharmaceutical and nutraceutical applications, ensuring compliance with cGMP norms and facilitating maintenance through a plug-and-play format change capability, making it an efficient, adaptable solution for varied batch sizes.

Benefits

- Enhances production efficiency with high-speed filling and capping, processing up to 150 bottles per minute.

- Minimizes changeover time with plug-and-play format adaptability, increasing line flexibility.

- Ensures product integrity and compliance with 100% weight and precise 2D/3D verification systems.

- Reduces operational downtime through autonomous bottle handling and synchronized transport.

- Complies with cGMP standards, maintaining consistent quality and safety in pharmaceutical production.

- Applications

- Supplements, Vitamins, Pharmaceutical tablets, Nutraceuticals, Pills, Capsules

- End products

- Omega-3 fish oil capsules, Herbal capsules, Vitamin c tablets, Ibuprofen pills, Calcium pills, Multivitamin tablets, Iron supplements, Paracetamol tablets, Glucosamine supplements, Effervescent vitamin c tablets

- Steps before

- Tablet Preparation, Capsule Formulation, Pill Manufacturing

- Steps after

- Capping, Labeling, Packing

- Input ingredients

- tablets, capsules, pills, bottles, caps

- Output ingredients

- filled and capped bottles, validated count, printed caps, rejected defective products

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Speed

- 150 bottles/min

- Automation Level

- Fully Automated

- Counting Channels

- 24 channels (two groups of 12)

- Torque Control

- Independent brushless motor

- Format Change Method

- Plug and Play

- Bottle Size Range

- Ø 30 - 125 mm

- Bottle Height Range

- 50 - 220 mm

- Closure Diameter

- 10 - 80 mm

- Closure Height

- 10 - 32 mm

- Tablet Size Range

- Ø 5 - 20 mm

- Capsule Sizes

- 000 to 5

- Product Tracking

- RGB Camera

- Weight Control Resolution

- 0.01 gr

- Working Mechanism

- Monoblock with autonomous shuttle system

- Integrated Steps

- Filling and Capping

- Batch vs. Inline Operation

- Batch for small or medium-sized batches

- Format Change Efficiency

- Plug and Play

- Speed of Operation

- Up to 150 bottles/min

- Automation Level

- Integrated Control System with Brushless Motors

- Flexibility in Product Handling

- Modular channels with twin flap function

- Changeover Time

- Rapid with minimal downtime

- Quality Control Measures

- Weight control, RGB cameras for product verification

- Validation Techniques

- 2D and 3D control by cameras

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Plug, play

- Format change

- Plug, play format replacement

- Transport system

- Magnetic movement system

- Independent handling

- Autonomous shuttle movement

- Capping head type

- Independent brushless motor

- Orientation and feeding system

- Eco 400 elevator/orientator