Automated visual inspection for pharmaceutical products

Ensure the integrity and safety of your parenteral products with cutting-edge automated visual inspection, capable of detecting particulate and cosmetic defects, optimizing quality assurance, and enhancing production efficiency.

Detects Particulate and Cosmetic Defects

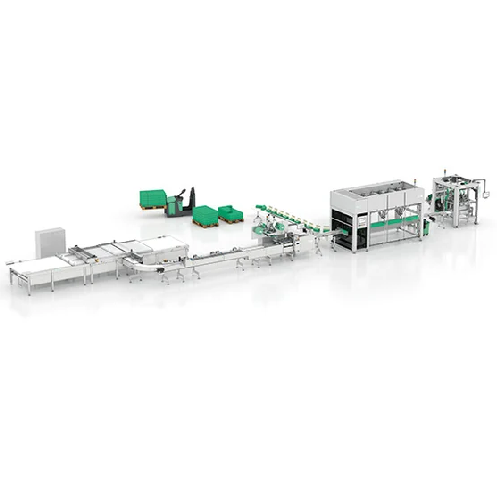

The AIM 8000 series from Syntegon represents cutting-edge technology in automated visual inspection systems. These machines specialize in the detection of particulate and cosmetic defects in pharmaceutical products, such as ampoules, vials, syringes, and cartridges. Using high-resolution camera systems and AI-driven image analysis, the AIM 8000 series enhances inspection accuracy while minimizing false rejects.

With its modular design, the AIM 8000 series accommodates a variety of container sizes and formats, ranging from 1 ml to larger capacities, ensuring flexibility in handling different products like insulin vials, vaccines, and biologics in cartridges. The system offers a throughput of up to 600 containers per minute, integrating seamlessly into both continuous and batch production lines.

Designed for efficiency, these machines utilize intelligent pre-spinning functions to homogenize products and eliminate air bubbles, further optimizing the inspection process. The incorporation of PLC control facilitates seamless automation and integration with existing line setups, while maintaining energy efficiency with its optimized motor systems.

Constructed from high-grade stainless steel, the AIM 8000 series ensures durability and resistance to corrosion, meeting stringent GMP and FDA compliance standards essential for pharmaceutical applications. Additionally, it features a built-in re-inspection function and supports Container Closure Integrity (CCI) testing, solidifying its role as a critical component in maintaining product safety and quality.

Engineered for ease of use, the series supports quick changeovers and includes customizable features to meet specific production needs, backed by Syntegon’s engineering support for tailored solutions.

Benefits

- Enhances product safety by reliably detecting defects and particles, ensuring higher quality standards.

- Minimizes the risk of false rejections using AI-driven image processing, reducing waste and improving efficiency.

- Increases operational flexibility with modular design to accommodate various container formats and sizes.

- Streamlines integration with existing production lines through PLC-controlled automation.

- Ensures compliance with GMP and FDA standards, supporting pharmaceutical regulatory requirements.

- Applications

- Liquid formulations, Syringes, Lyophilizates, Nutraceuticals, Insulin, Tablets, Vials, Biopharmaceuticals, Ampoules, Functional sweets, Cartridges, Parenteral products, Powders, Capsules, Pharmaceuticals

- End products

- Infusion solutions, Glucose ampoules, Antiviral injections, Effervescent tablets, Cough syrups, Energy tablets, Plant-based capsules, Hormonal injectables, Oral suspension powders, Vaccines, Collagen supplements, Lyophilized antibiotics, Insulin vials, Nutritional gel capsules, Chemotherapy drugs, Pre-filled insulin pens, Pain relief vials, Pre-filled syringes, Biologics in cartridges, Vitamin capsules

- Steps before

- Filling, De-nesting, Pre-sorting of gross defects, Product homogenization

- Steps after

- Re-nesting, Capping, Coding, Packing, Labeling

- Input ingredients

- ampoules, vials, cartridges, syringes, liquids, lyophilizates, powders

- Output ingredients

- inspected ampoules, inspected vials, inspected cartridges, inspected syringes, defect-free containers, quality-assured products

- Market info

- Syntegon is known for its expertise in processing and packaging technology, offering innovative solutions for the food and pharmaceutical industries. It has a strong reputation for advanced equipment, sustainability, and customer-oriented service.

- Detection type

- Vision / AI-powered

- Inspection Speed

- Up to 600 containers per minute

- Container Size Range

- 1 ml – 50 H

- Respin Function

- Pre-spinning for homogenization and air bubble elimination

- Module Integration

- High Voltage Leak Detection (HVLD)

- Automation

- Fully automated / AI-capable

- Camera Technology

- High-resolution CMOS cameras

- Lighting

- LED reflection and transmission lights

- Software

- Advanced vision tools with AI integration

- Material Handling

- No glass-to-glass contact

- Operating Function

- Built-in re-inspection

- Spinning Profiles

- Individual direct drives (48 servo motors)

- Accuracy

- Supports AI for enhanced detection capabilities

- Automation level

- Manual / Semi-automated / Fully automated

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Changeover time

- Quick changeover capabilities

- Energy efficiency

- Optimized energy consumption

- Pre-spining function

- Available for product homogenization

- Inspection method

- Visual / AI-enhanced

- Inspection station integration

- Pre-inspection station for pre-sorting of gross defects

- AI integration

- Deep learning algorithms for enhanced detection

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Syringes, vials, cartridges, ampoules

- Container size

- 1 ml – 50 ml

- Machine footprint

- Compact and modular

- Container capacity

- 1 ml – 50 H

- Pre-sorting capability

- Pre-inspection station for gross defects

- Assembly type

- Complex syringe assembly handling

- Handling type

- De-nesting and re-nesting

- Control panel type

- Touchscreen HMI

- Integration Possibilities

- SCADA/PLC compatible

- Modules

- Modular design for customization

- Footprint

- Compact/Small

- Vision System

- AI-ready with deep learning algorithms

- Machine Design

- Modular and customizable