Integrated counting system for tablets and capsules

Streamline your packaging line with a highly versatile system that seamlessly combines container loading, counting, filling, and capping functions, ensuring precise dosage and minimal downtime for your tablet and capsule production.

Counts, Fills, and Caps Tablets and Capsules

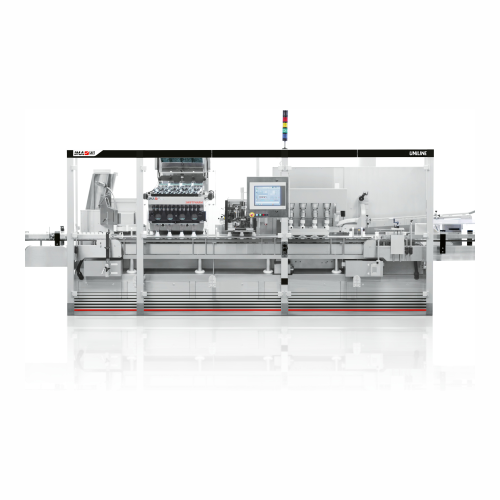

The UNILINE Integrated Counting and Filling System from IMA Group revolutionizes pharmaceutical and nutraceutical production lines by seamlessly integrating conveying, filling, and capping processes into a single, compact unit. This system stands out with its quick-changeover capability, eliminating the need for size change parts and enabling immediate startup at full production speed. Its balcony design ensures easy cleanability and operation visibility, eliminating hidden entrapment points. Equipped with advanced optical and electronic field sensors, UNILINE guarantees precise counting even under challenging conditions. It supports a wide range of bottle shapes, including round, rectangular, oval, and square, and accommodates various product outputs, handling up to 150 bottles per minute and 12,000 tablets per minute. With a focus on energy efficiency, the system minimizes energy consumption, and its PLC-controlled operations facilitate integration into existing lines. Built with compliance in mind, UNILINE meets GMP standards, ensuring reliable performance across pharmaceutical and nutraceutical sectors.

Benefits

- Achieves rapid changeovers, increasing production flexibility and minimizing downtime.

- Ensures precise product handling and count accuracy with advanced sensor technology.

- Reduces labor and operational costs through full automation and PLC control.

- Minimizes space requirements with a compact and efficient design.

- Enhances line integration adaptability, accommodating diverse container shapes and sizes.

- Applications

- Vitamins, Supplements, Pharmaceutical tablets, Nutraceuticals, Capsules, Pharmaceuticals

- End products

- Magnesium tablets, Vitamin d capsules, Digestive enzyme capsules, Fish oil softgels, Vitamin c tablets, Zinc supplements, Probiotic capsules, Herbal supplements, Vitamin b complex capsules, Calcium tablets, Omega-3 supplements, Multivitamin tablets, Iron supplements

- Steps before

- Container loading preparation, Material preparation, Product counting setup

- Steps after

- Sterilization, Packing, Quality control

- Input ingredients

- containers, desiccants, tablets, capsules, cotton, rayon, polyester

- Output ingredients

- filled bottles, capped bottles, counted tablets, counted capsules, inserted desiccant, inserted cotton

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Automation

- Fully Automatic

- Bottle Output

- Up to 150 bpm

- Product Output

- 12, 000 tablets/min

- Bottle range

- Min

- Cap range

- 10 mm (0.44″) to 70 mm Dia. (2.75″)

- Count Accuracy

- High with optical sensor and E.F.S.

- Changeover Time

- Quick with no product or bottle change parts

- Bottle Handling

- Round, rectangular, oval and square

- Energy Consumption

- Reduced to a minimum

- Conveying,filling,and capping system

- Integrated

- Integrated process steps

- Container loading, desiccant insertion, counting and filling, cotton insertion, capping, rejection

- Flexibility

- High, with quick changeover and no product/bottle change parts required

- Counting technology

- Optical sensor and Electronical field sensor

- Batch operation

- Small batch adaptability

- Cleanability

- Balcony design for easy cleaning

- Changeover time

- Quick, automatic with the touch of a button

- Control system

- HMI available

- Automation level

- Automated bottle size changeover

- Energy efficiency

- Reduced energy consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Fits in a fraction of the space of traditional equipment

- Machine layout

- Balcony design for easy cleanability and visibility

- Bottle range dimensions (Min)

- 30 mm (1.18″) diameter and width

- Bottle range dimensions (Max)

- 180 mm (7.00″) height

- Capping type

- CRC, Screw Top, Flip Top, Press on

- Desiccant type

- 1, 2, and 3 gram – 1 to 3 canisters per bottle

- Cotton type

- Cotton, Rayon, Polyester

- Control panel type

- HMI (Human-Machine Interface)

- Bottle size changeover

- Automatic

- Compact design

- Space-efficient

- Flexibility

- No product or bottle change parts