Blister packaging solution for small/medium batches

Achieve high production efficiency with frequent changeovers for your tablet and capsule packaging, ensuring swift transitions and minimized downtimes.

Packages Pharmaceutical Tablets and Nutraceuticals Efficiently

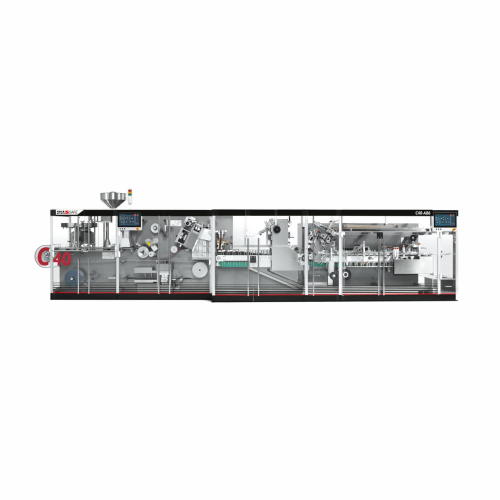

The C40 Blister Packaging Machine from IMA Group is engineered for high-speed pharmaceutical and nutraceutical applications, efficiently streamlining the packaging of tablets, capsules, and supplements. It integrates seamlessly into existing lines with flexible layouts and connects easily to downstream equipment like cartoners. Capable of producing up to 525 blisters/minute, the C40 stands out with its reduced format parts, facilitating swift changeovers and minimal downtime. Energy consumption is minimized through optimized operations, and sustainable packaging materials are supported. The machine ensures robust track and trace capabilities with integrated serialization for compliance, coupled with easy access for maintenance and cleaning.

Benefits

- Enhances production efficiency by handling up to 525 blisters per minute.

- Minimizes operational costs with easy-to-access design for quick cleaning and maintenance.

- Supports sustainable practices through compatibility with recyclable and compostable materials.

- Facilitates rapid changeovers, reducing downtime in high-mix production environments.

- Ensures regulatory compliance with integrated track and trace serialization.

- Applications

- Nutraceuticals, Vitamins, Supplements, Pharmaceutical tablets

- End products

- Aspirin tablets, Calcium supplements, Vitamin c tablets, Fish oil capsules

- Steps before

- Tablet Pressing, Material Loading, Pre-heating, Forming

- Steps after

- Cartoning, Labeling, Serialization, Distribution

- Input ingredients

- blister packaging materials, recyclable materials, compostable materials

- Output ingredients

- blisters, cartons, packaged products

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Production Rate (Blisters)

- Up to 350 blisters/min (2 rows configuration)

- Production Rate (Blisters)

- Up to 525 blisters/min (3 rows configuration)

- Production Rate (Cartons)

- Up to 160 cartons/min

- Production Rate (Cartons)

- Up to 350 cartons/min

- Blister Dimensions (Width)

- 30-90 mm

- Blister Dimensions (Length)

- 60-220 mm

- Blister Dimensions (Depth/Height)

- 3-12 mm

- Carton Dimensions (Width)

- 35-95 mm

- Carton Dimensions (Length)

- 65-150 mm

- Carton Dimensions (Depth/Height)

- 12-110 mm

- Changeover Time

- Reduced/minimized

- Energy Consumption

- Reduced to a minimum

- Compatibility

- Recyclable/compostable materials

- Integration Capability

- Cartoner, wallet packer, flowpacker, end-of-line

- Track,Trace Module

- Camera and ink-jet system for serialization

- Changeover time

- Fast and simple changeovers

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Cleaning method

- Easy cleaning operations

- Energy efficiency

- Reduced energy consumption

- Recyclable material compatibility

- Yes

- Compostable material compatibility

- Yes

- Machine footprint

- Compact

- Blister configuration

- 2 rows or 3 rows

- Compact footprint

- Yes

- Control panel type

- Accessible

- Discharge method

- Connected to cartoner

- Control panel type

- Integrated HMI

- Integration possibilities

- Compatible with cartoner, wallet packer, flowpacker or end-of-line

- Layout flexibility

- Yes, flexible layout options

- Connection options

- Compact and reliable connection with other equipment

- Format parts

- Reduced to a minimum