Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system designed for precise dosing and reliable sealing of liquid to viscous products, ensuring consistent quality in your personal care and pharmaceutical goods.

Fills and Seals Tubes for Diverse Products

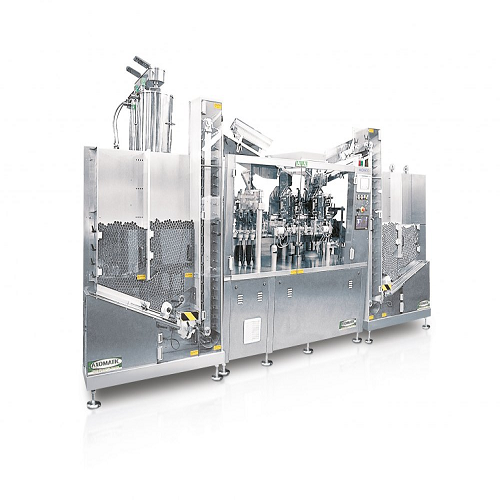

The AXO 4800 by Axomatic is an automatic tube filling and closing machine designed for high-speed operations in the pharmaceutical, cosmetics, food, personal care, and chemical industries. It utilizes a stainless steel AISI 304 and 316L construction for durability and corrosion resistance, with integrated electric control for ease of use. The machine features four independent dosing groups driven by separate servomotors, providing precise dosing from 3 to 250 ml for liquid, semi-viscous, and viscous products such as toothpaste, lotions, and gels. Its ergonomic tube loaders and Industry 4.0-ready touch screen control panel enhance operational efficiency and ease of integration into production lines. With a capacity of 275 pieces per minute, it offers significant processing throughput. Options for hot air sealing, customization of sealing systems, and compliance with CFR 21 PART 11 ensure versatile and secure operations, while an optional CIP system and full ATEX certification further enhance safety and maintenance capabilities.

Benefits

- Enhances production efficiency with high-speed operation of up to 275 tubes per minute.

- Ensures precise product dosing and minimizes material waste with sophisticated servo-driven dosing groups.

- Simplifies integration and monitoring with Industry 4.0-ready touch screen controls.

- Supports compliance and safety with optional CFR 21 PART 11 adherence and ATEX certification.

- Facilitates quick and thorough cleaning, reducing downtime with an optional CIP system.

- Applications

- Viscous products, Liquid formulations, Semi viscous products

- End products

- Lotion, Sunscreen, Liquid soap, Toothpaste, Adhesive, Facial cream, Ointment, Gel-based hair products

- Steps before

- Mixing, Emulsification, Preparation, Material Loading

- Steps after

- Sealing, Inspection, Packing, Labeling

- Input ingredients

- liquid products, semi viscous products, viscous products, collapsible metal tubes, plastic tubes, laminate tubes

- Output ingredients

- filled metal tubes, filled plastic tubes, filled laminate tubes

- Market info

- Axomatic, part of the Marchesini Group, is known for manufacturing high-quality automated machinery for packaging, particularly in the cosmetic, pharmaceutical, and food industries, with a reputation for innovation and customization in engineered-to-order equipment.

- Speed

- 275 pieces per minute

- Dosing range

- 3 to 250 ml

- Tube diameters

- 13.5-50 mm

- Tube heights

- 70-220 mm

- Number of turntable stations

- 48

- Material

- Stainless Steel AISI 304/316L

- Automation

- Industry 4.0 compatible

- Sealing system

- Hot air sealing with low air consumption

- Stroke

- 120 mm adjustable

- Electric control

- Integrated in the machine perimeter

- Automation level

- Automatic

- Cleaning method

- Easy cleaning

- Batch vs. continuous operation

- Batch

- Dosing system

- Four independent dosing groups

- Sealing system

- Hot air sealing

- Control panel type

- Touch screen

- Industry compatibility

- Industry 4.0

- Tube loading

- Ergonomic tube loaders

- Corrosive resistance (e.g. acids)

- High (Stainless Steel AISI 316L)

- Cleanability

- Easy cleaning of parts in contact with product

- Container type

- Metal, plastic, laminate tubes

- CFR 21 PART 11

- Yes

- ATEX certification

- Full Atex certification (option)

- Construction Material

- Stainless Steel AISI 304L

- Control Panel Type

- Touch Screen

- Tube Loader Capacity

- Large Capacity

- Nozzle Type

- Diving Nozzles

- Nozzle Stroke

- Adjustable Stroke 120 mm

- Turntable Stations

- 48 Stations

- Sealing system

- Customised sealing systems

- Dosing groups

- Four independent, adjustable stroke