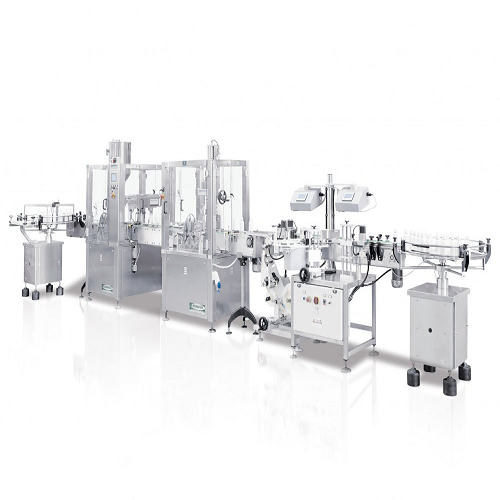

Linear filling and capping for stable bottles

Enhance your production efficiency with a solution designed for precise liquid filling and capping, tailored to handle a wide range of container types while maintaining high-speed operations.

Fills and Caps Bottles with Liquid Products

The linear bottle filling and capping machine is an engineered solution designed for continuous, high-speed liquid packaging applications. Ideal for industries like pharmaceuticals, cosmetics, food and beverage, and chemicals, it efficiently fills and caps containers ranging from syrups and essential oils to shampoos and sauces. Leveraging a linear design, it enables a seamless flow of operation, ensuring precision in filling and secure capping. With PLC control, it integrates smoothly into existing production lines, enhancing automation. The machine accommodates varying container sizes and materials, and supports clean-in-place (CIP) systems for efficient maintenance. Built with stainless steel, it ensures durability and corrosion resistance, meeting GMP standards crucial for compliance in sensitive production environments. This machine is customizable to meet specific throughput requirements and includes engineering support for tailored configurations.

Benefits

- Enhances production efficiency with continuous, high-speed operation.

- Reduces operational costs through precise filling and capping automation.

- Ensures compliance with GMP standards for pharmaceutical and cosmetic products.

- Flexible design accommodates a variety of liquid containers and sizes.

- Simplifies maintenance with integrated clean-in-place (CIP) system.

- Applications

- Packaging solutions, Liquid formulations, Cosmetic products, Food and beverage products, Bottling operations, Chemical solutions

- End products

- Lotion bottles, Sauce bottles, Mouthwash, Vinegar bottles, Beverage bottles, Liquid detergent containers, Cream jars, Syrups, Shampoo bottles, Essential oils

- Steps before

- Bottle preparation, Cleaning, Labeling

- Steps after

- Capping inspection, Product labeling, Final packaging

- Input ingredients

- Output ingredients

- Market info

- Axomatic, part of the Marchesini Group, is known for manufacturing high-quality automated machinery for packaging, particularly in the cosmetic, pharmaceutical, and food industries, with a reputation for innovation and customization in engineered-to-order equipment.

- Filling type

- Linear

- Capping type

- Automatic

- Container stability

- Stable bottles

- Machine type

- Filling and Capping Machine

- Configuration

- Available in several solutions

- Filling and capping process

- Linear operation for stable bottles

- Automation level

- PLC-controlled / Fully automated

- Changeover time

- Quick-change capability

- CIP/SIP

- CIP available

- Cleaning method

- CIP

- Container type

- Stable bottles

- Footprint

- Compact

- Machine type

- Linear filling and capping

- Bottle compatibility

- Stable bottles

- Modular design

- Available

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- ERP / MES systems

- Bottle size adaptability

- Various sizes

- Cap type adaptability

- Multiple options