Filling and closing solution for plastic bottles

Efficiently sort, fill, and close a variety of plastic bottles with precise dosing and gentle handling, ensuring product integrity and compliance in pharmaceutical and nutrient liquid production.

Sorts, Fills, and Closes Liquid Products

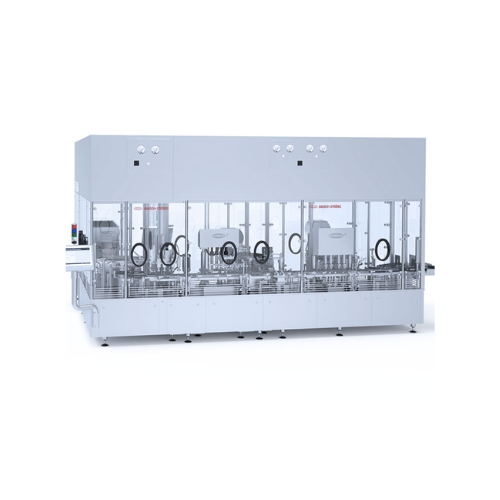

The FVK 50400 from Bausch+Ströbel is a fully automatic filling and closing machine designed for precision handling of liquid products in pharmaceutical and biotech industries. This intermittent motion system gently conveys containers using a walking beam, ensuring minimal mechanical stress. With options for rotary piston or peristaltic pumps, it accommodates a range of liquid formulations, including cough syrups and essential oils.

Capable of processing up to 10,000 items per hour, the FVK 50400 efficiently manages sorting, filling, closing, and inspection processes, with options for droppers, screw caps, and snap-on closures. The machine’s 100% In-Process Control (IPC) at maximum output ensures compliance with stringent quality standards while the sterilizable parts facilitate maintenance and adhere to clean room requirements.

With a design optimized for laminar air flow, it integrates seamlessly into both processing and packaging departments, offering compatibility with various inspection, checking, and alarm systems. Its flexible design supports GMP compliance, making it an ideal choice for manufacturers aiming for uncompromising production efficiency and quality assurance.

Benefits

- Enhances production efficiency with a throughput of up to 10,000 items per hour.

- Ensures product integrity with gentle container handling using a walking beam system.

- Minimizes contamination risk with fully sterilizable components suitable for clean room environments.

- Provides advanced quality control with 100% In-Process Control (IPC) at full output.

- Customizable dosing options reduce variability and meet diverse liquid formulation requirements.

- Applications

- Nutraceuticals, Essential oils, Liquid formulations, Pharmaceuticals

- End products

- Liquid probiotic supplement, Cough syrup, Vitamin d supplement liquid, Eucalyptus essential oil, Peppermint essential oil, Liquid paracetamol suspension, Omega-3 fish oil supplement, Lavender essential oil

- Steps before

- Sorting, Container preparation, Container cleaning

- Steps after

- Labeling, Tray loading, Inspection, Reject discharge, Packing

- Input ingredients

- plastic bottles, liquid products, droppers, screw caps, snap-on caps, multi-dose dispensers

- Output ingredients

- filled plastic bottles, closed plastic bottles

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Automation

- Fully automatic

- Max Output

- 10, 000 items/h

- Container Diameter

- 14.25 - 30 mm

- Container Height

- 30 - 67 mm

- Dosing System

- Rotary piston pumps / Peristaltic pumps

- Closure Types

- Droppers / Screw caps / Snap-on caps / Multi-dose dispensers

- Sterilizable Parts

- Yes

- In-Process Control (IPC)

- 100% at full output

- Working mechanism

- Intermittent motion

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Intermittent

- Cleaning method

- Sterilizable / Autoclavable components

- Product handling

- Gentle container transport

- Sorting and filling steps

- Automatic sorting, filling, and closing of plastic bottles

- Closure types

- Droppers, screw caps, snap-on caps, multi-dose dispensers

- Cleanability

- Sterilizable / Autoclavable

- Container diameter range

- 14.25 - 30 mm

- Container height range

- 30 - 67 mm

- Control panel type

- Easy and centralized operation

- Discharge method

- Walking beam system

- Dosing system type

- Rotary piston or peristaltic pumps

- Container closure type

- Droppers, screw caps, snap-on caps, multi-dose dispensers

- Output rate

- Max. 10, 000 items/h

- Container size compatibility

- Diameter

- In-Process Control (IPC)

- 100% IPC at full output

- Laminar air flow system

- Optimal

- Inspection options

- Wide range available

- Service Portal Vision System

- Suitable for clean rooms

- Software upgrades

- Available

- Qualification

- IQ/OQ

- Reject discharge system

- Available

- Closure feed system

- From supply system