Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing processes with a system designed to integrate solids seamlessly into liquids, enhancing product quality while maintaining storage stability.

Homogenizes and Emulsifies Industrial-Scale Products

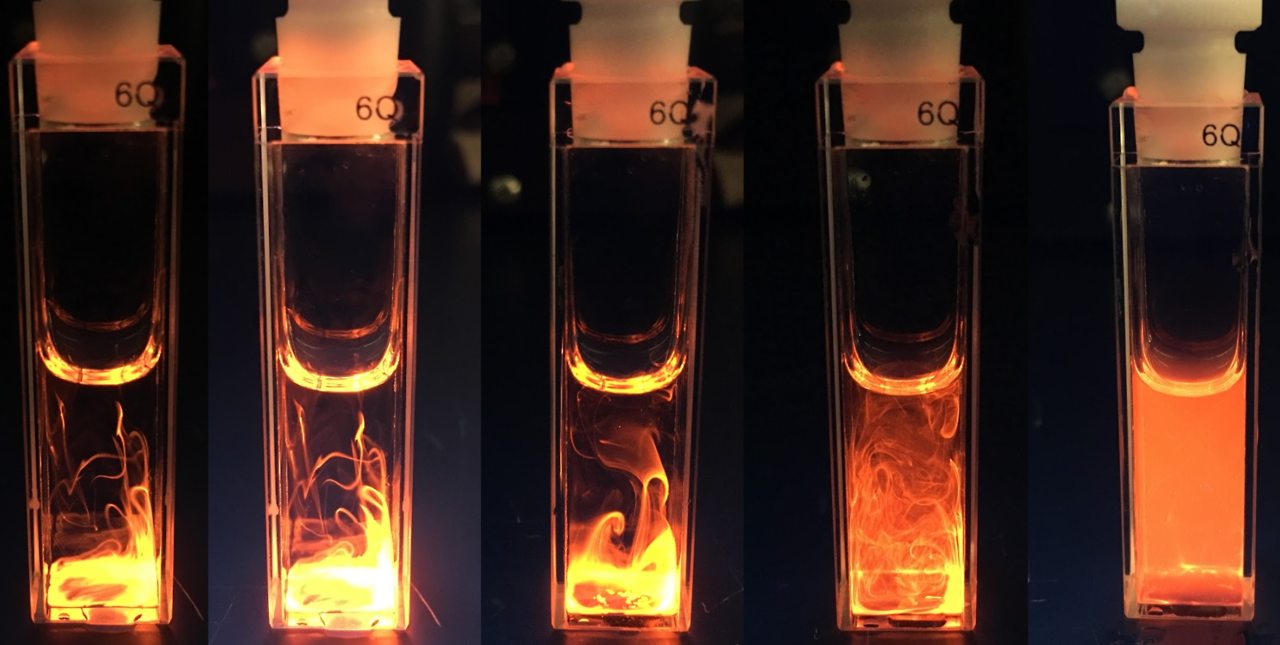

The Hydro Grind® Processing system from AK System GmbH is designed to finely homogenize and emulsify solids into liquids, serving industries like food, cosmetics, chemicals, and pharmaceuticals. The equipment integrates a patented homogenizing unit capable of efficiently creating fine droplet emulsions and suspensions through a high-pressure homogenization process. With the ability to perform multiple processing steps—homogenization, emulsification, mixing, dosing, size reduction, and deaeration—in a single unit, it supports continuous operation at an industrial scale.

Applications include producing mayonnaise, salad dressings, skin creams, lotions, shampoos, and pharmaceutical creams, among others. Its dynamic shear force adjustment allows for the flexible handling of shear-sensitive materials while maintaining high product quality. The system includes a direct solids dosing feature at the dispersing turbine, ensuring even dispersion and preventing lump formation.

The Hydro Grind® is constructed for efficiency and hygiene, offering a cost-effective alternative by reducing the need for system changes. It is compatible with various materials, meeting industrial standards for quality and performance assurance, and supports CIP systems for easy cleaning.

Benefits

- Enhances product quality with precise emulsification and homogenization, ensuring uniform end-products.

- Saves operational costs by integrating multiple processes in one unit, reducing system changeovers.

- Increases production flexibility with adjustable shear forces for diverse material viscosities.

- Improves hygiene and reduces contamination risks through direct solids dosing and efficient system cleaning.

- Optimizes energy consumption during processing, contributing to economic and environmental benefits.

- Applications

- Food, Suspensions, Chemical products, Cosmetics, Emulsions, Pharmaceutical products

- End products

- Nutraceutical emulsions, Vaccines, Pharmaceutical creams, Fabric softener, Liquid detergents, Latex emulsions, Paint emulsions, Skin creams, Salad dressings, Chemical suspensions, Polymer emulsions, Ointments, Mayonnaise, Shampoo, Lotions, Conditioners

- Steps before

- Initial formulation, Ingredient mixing, Pre-emulsification

- Steps after

- Storage stabilization, Product packaging, Quality control

- Input ingredients

- solids, liquids, shear-sensitive goods

- Output ingredients

- emulsions, homogenized fine droplet structures, suspensions, storage-stable products, highly viscous emulsions

- Market info

- Homogenizing Unit Type

- Hydro Grind® Processing

- Shear Force Adjustment Range

- Dynamically controlled

- Emulsion Type

- Fine droplet structure

- Direct Dosing Capability

- In dispersing turbine

- Process Integration

- All in one

- Application Sectors

- Food, cosmetics, chemical, pharmaceutical

- Production Scale

- Industrial scale

- Product Stability

- Storage-stable

- Working mechanism

- Homogenizing unit

- Integrated steps

- All-in-one procedure

- Batch vs. continuous operation

- Batch / Inline Continuous

- Shear force control

- Dynamically controlled

- Direct dosing capability

- Dispersing turbine area

- Changeover time

- Minimal due to all-in-one setup

- Automation level

- Manual / PLC / SCADA

- Cleaning method

- Presumed CIP due to hygienic advantages

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact

- Integration of process steps

- ALL IN ONE system

- Shear-sensitive compatibility

- Yes

- Homogenizing unit design

- Self-developed, for fine droplet structure

- Direct solid dosing

- Yes

- Dispersing turbine location

- Within the system

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / PLC systems

- Shear force adjustment

- Dynamically controlled

- Mixing capabilities

- Emulsion / Suspension

- Process flexibility

- Batch / Continuous