Explosion-proof rotary vane vacuum pump

Ensure safety and efficiency in flammable environments with this explosion-proof vacuum pump, designed for critical gas removal and pressure reduction in demanding petrochemical and chemical processes.

Generates Vacuum and Reduces Pressure Safely

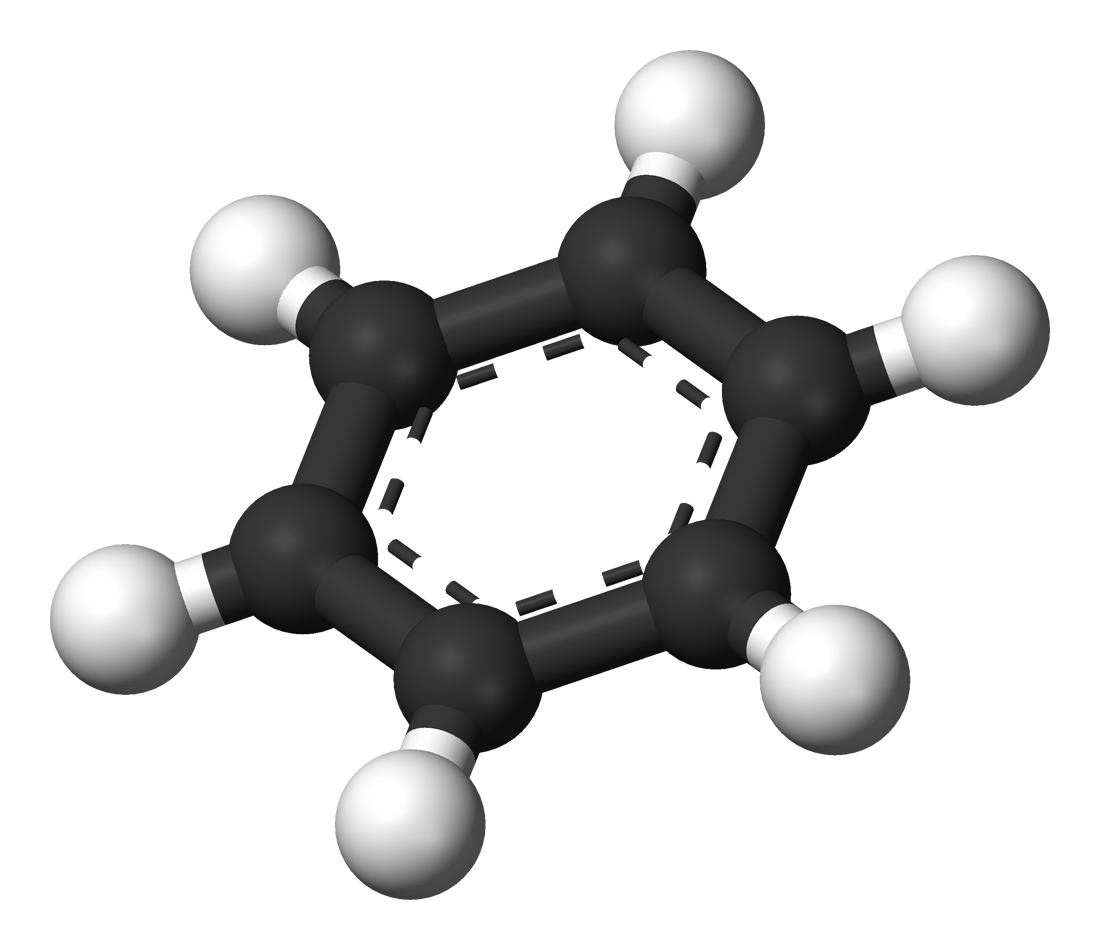

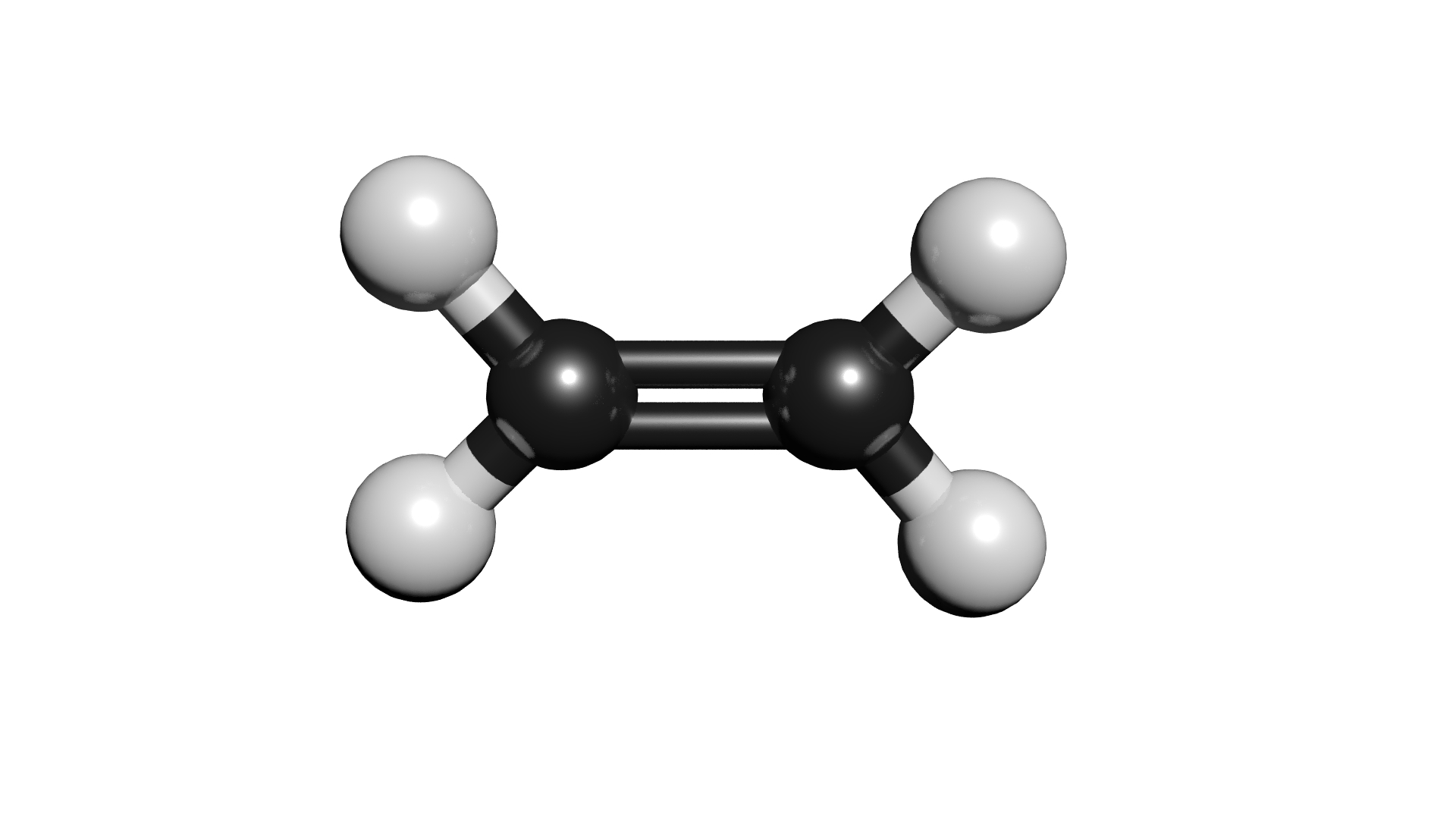

The Welch CRVPro Rotary Vane Vacuum Pump, equipped with an explosion-proof motor, is designed specifically for petrochemical, chemical, and oil extraction industries. Its two-stage direct-driven design ensures reliable vacuum generation, essential for evacuating flammable and volatile gases. The pump offers free air displacement capacities from 2.8 cfm to 12.8 cfm, achieving ultimate pressures as low as 2×10⁻³ torr. This capability makes it ideal for applications involving ethylene, benzene, and solvent-based paints. Engineered for robust performance, it features a built-in oil filtration system and a larger oil chamber to minimize risk of chemical attacks, promoting extended operational intervals. The CRVPro series is cUL listed and rated for Class I, Groups C&D, and Class II, Groups F&G, ensuring compliance in explosive environments. Its manual or continuous operation, paired with a specialized coating on the pump module, provides resistance against corrosive vapors, integrating seamlessly into safety and environmental control measures within processing lines.

Benefits

- Ensures safety in explosive environments with an explosion-proof motor.

- Increases operational efficiency through enhanced vacuum performance.

- Extends maintenance intervals with corrosion-resistant design.

- Supports versatile applications in petrochemical and chemical processing.

- Minimizes chemical attack risks with a robust oil filtration system.

- Applications

- Chemicals, Oil extraction, Solvents, Petrochemicals, Flammable materials

- End products

- Propylene, Xylene, Kerosene, Pyrotechnic products, Benzene, Diesel, Ethylene, Solvent-based paints, Adhesives, Aerosols, Gasoline, Toluene, Explosive powders, Industrial coatings, Lubricating oils

- Steps before

- Extraction, Chemical Processing, Solvent Recovery

- Steps after

- Filtration, Distillation, Purification

- Input ingredients

- air, petrochemicals, chemical vapors, flammable solvents, oil

- Output ingredients

- vacuum, extracted chemicals, purified air

- Market info

- Precision Extraction Solutions is known for providing innovative, high-quality extraction equipment and solutions for the cannabis industry, specializing in systems that enhance efficiency and safety in extracting cannabinoids and essential oils.

- Pumping Speed

- 2.8 CFM

- Pumping Speed

- 5.6 CFM

- Pumping Speed

- 12.8 CFM

- Ultimate Pressure

- 1.5 Torr

- Power

- 120V / 1 ph

- Connection Flanges

- NW 16

- Inlet Hose Connection

- 5/8″ to 3/4″

- Weight

- 46.3 lbs

- Weight

- 49.6 lbs

- Weight

- 81.6 lbs

- Dimensions

- L 18.2″ x W 6.1″ x H 9.1″

- Dimensions

- L 22.4″ x W 8.1″ x H 11.4″

- Oil Capacity

- 1.15 L

- Oil Capacity

- 1 L

- Oil Capacity

- 2.4 L

- Explosion Proof Motor

- Yes

- Free Air Displacement

- 2.8 cfm – 12.8 cfm

- Ultimate Pressure Levels

- 2×10⁻³ torr

- Working mechanism

- Two-stage direct-driven

- Pressure range

- 2×10⁻³ torr to 1.5 Torr

- Free air displacement

- 2.8 cfm – 12.8 cfm

- Cooling method

- Cool running operation

- Oil capacity

- 1 L - 2.4 L

- Automation level

- Manual / Explosion-proof control panel needed

- Motor type

- Explosion-proof motor

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- CUL listing

- E485334

- Explosion-proof compliance

- Class I, Groups C, D

- Class II,Groups E,F,G

- Control panel type

- Explosion-proof control panel