High-precision dosing systems for aerospace applications

Achieve unmatched precision and reliability when dosing complex materials like core fillers and sealants in aerospace structures, ensuring minimal waste and optimal integration into your production line.

Automates Dosing, Mixing, and Filling in Aerospace

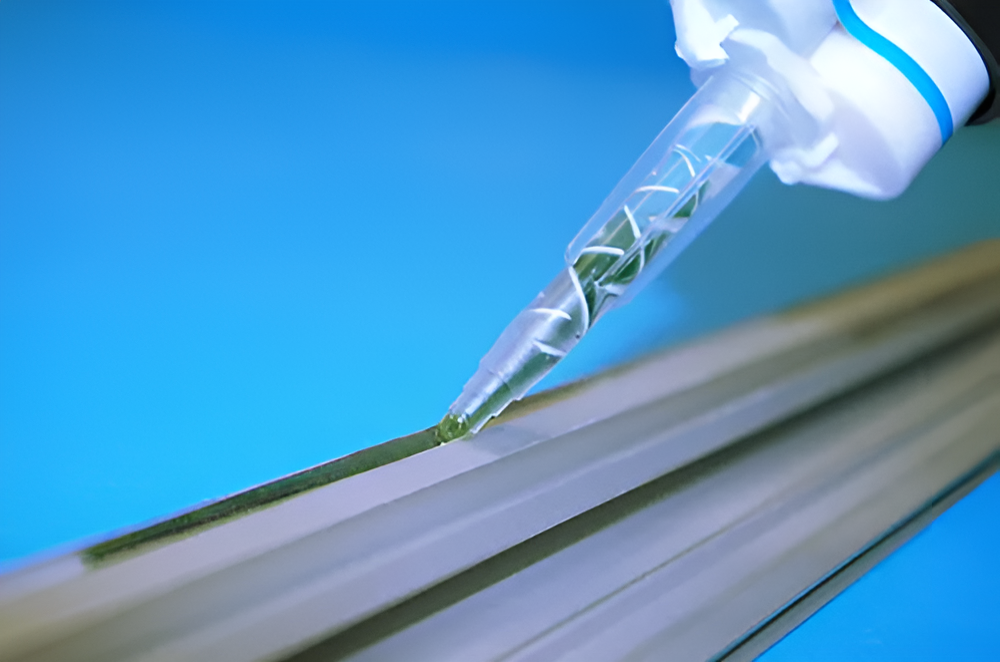

ViscoTec Pumpen- u. Dosiertechnik GmbH offers an innovative solution for aerospace manufacturing with their Precision Dosing and Mixing System. This equipment excels in automating complex processes such as dosing, bonding, sealing, and potting for materials like epoxy resins, polysulfides, and carbon fiber composites. Utilizing a volumetric dosing mechanism, it ensures precise application, reducing material waste and increasing process reliability. Specifically designed for aerospace applications, it handles the integration of structural components and satellite assemblies, supporting both continuous and automated operations. The system’s robust design allows processing of various viscosities without altering material properties, ensuring integrity in critical applications like honeycomb panel filling and two-component bonding for satellite components.

This system’s energy-efficient motor control reduces operational costs while its modularity supports integration into existing production lines. Equipped with pressure sensors and tailored nozzle designs, it guarantees accuracy and repeatability, addressing complex geometries with ease. Its compatibility with large containers minimizes material costs, offering significant savings for OEMs and aerospace suppliers. Additionally, ViscoTec provides extensive customization and engineering support to tailor the system’s capacities and features to specific production needs, ensuring optimal performance and compliance with stringent aerospace quality standards.

Benefits

- Minimizes material waste and reduces production costs with precise volumetric dosing.

- Increases production efficiency with automated processes, cutting labor and cycle times.

- Maintains material integrity in sensitive applications with gentle handling.

- Offers flexibility and adaptability with modular design for seamless integration.

- Enhances process reliability and quality control with pressure monitoring and tailored nozzle designs.

- Applications

- Sandwich panels, Sealants, Carbon fibre composites, Epoxy resins, Core fillers, Structural adhesives, Honeycomb structures, Aerospace adhesives, Thermal paste, Aerospace components, Aerospace sealants, Polysulfides

- End products

- Solar panels for satellites, Core-filled sandwich panels for aviation, Carbon fiber composite wing sections, Polyurethane-filled inserts for aerospace, Two-component polysulfide sealed joints, High-precision aerospace sealants, Epoxy resin bonded components, 2-component thermal paste bonded electronic components in satellites, Honeycomb-filled panels for aircraft interiors, Fuselage composite structures, Structural adhesive bonded fuselage

- Steps before

- Material Preparation, Component Mixing, Process Simulation, Material Removal from Large Containers

- Steps after

- Component Bonding, Edge Sealing, Process Validation, Quality Control, Reproducible Production

- Input ingredients

- one-component epoxy resins, two-component epoxy resins, hollow glass spheres, carbon fibre composites, two-component polysulphides, compressible fluids, compressible pastes, premixed-frozen cartridges, hardener rod cartridges, epoxy resins, polysulfides, polyurethanes, hollow spheres

- Output ingredients

- bonded structural components, sealed edges, potted honeycombs, sealed rivets and screws, reproducible production components, reduced material waste, filled sandwiches and inserts, sealed connection surfaces, clean thread breakage, dosed fluids and pastes, optimized production processes, high-quality connections

- Market info

- Visco Tec is known for its precision dispensing and dosing technology, specializing in equipment for viscoelastic fluids, offering reliable, high-quality solutions for industries like pharmaceuticals, food, cosmetics, and general manufacturing, renowned for engineering excellence and innovation.

- Automation

- Fully automated

- Accuracy

- High-precision dosing

- Dosing type

- Volumetric dosing

- Material handling

- Gentle for shear-sensitive materials

- Mixing type

- Static mixing

- Continuous dosing

- Yes

- System control

- Pressure sensor monitoring

- Container size handling

- Large containers

- Cycle time

- Shortened throughput time

- Working Mechanism

- Endless Piston Principle

- Automation Level

- PLC-controlled/SCADA

- Batch vs. Continuous Operation

- Continuous Dosing

- Material Handling

- Gentle product handling

- Integration with Robots

- Compatible with robotic systems

- Mix-on-demand System

- Mobile and semi-automatic

- Energy Efficiency

- Cost savings through large container usage

- Pressure Control

- Through pressure sensors

- Abrasion resistance

- Yes

- Shear-sensitive materials

- Yes

- Compressible materials

- Yes

- Hollow glass spheres

- Yes

- Epoxy resins

- 1- and 2-component

- Polysulfides

- Two-component

- Core and edge fillers

- Yes

- Adhesives and sealants

- Yes

- Fluid type

- Adhesives / Sealants / Epoxy Resins

- Machine footprint

- Compact / Customizable

- Feed method

- Continuous feed from large container

- Discharge method

- Volumetric dosing

- Tank shape or size

- Hobbocks / Drums / Cartridges

- Nozzle design

- Customizable for application

- Pulsation-free dispensing

- Yes

- Control panel type

- Touchscreen / HMI / PLC

- Integration possibilities

- Robot / Axis System Integration

- Nozzle Design

- Tailored for Complex Geometries

- Process Simulation

- In-house Technical Center

- Material Supply

- Large Containers to Cartridges