Gravimetric dosing systems for precise material measurement

Achieve precise material measurement with gravimetric dosing systems, ensuring consistent quality and optimized batch processes in your production line.

Accurately Weighs and Mixes Solids and Liquids

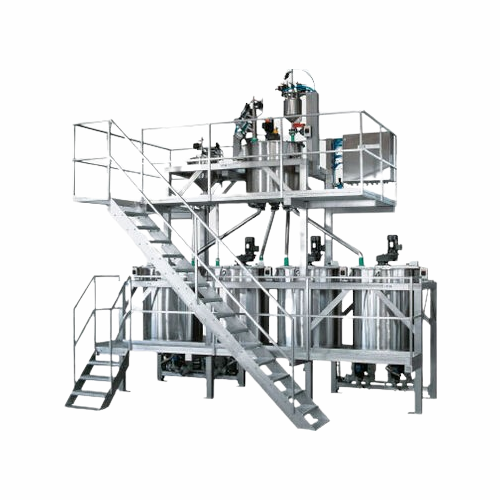

The IFA-Gravimet from IFA Technology is a versatile gravimetric dosing system designed for accurate weighing and mixing of raw materials in various industrial applications. Its unique weight-controlled dosing mechanism, using load cells or weighing cells, ensures precise material handling for high-quality production of products such as epoxy adhesives and phenolic resins. Suitable for sectors ranging from automotive to pharmaceuticals, the system integrates seamlessly into both batch and continuous operations, offering customization options to fit specific production needs. With PLC automation, the system ensures data acquisition and batch traceability, optimizing processes with integrated consumption data acquisition. Constructed from durable materials, IFA-Gravimet complies with industry standards, accommodating corrosive environments. Its design facilitates easy cleaning and maintenance, minimizing downtime and enhancing efficiency. Custom engineering support is available to tailor the system to your specific requirements, ensuring seamless integration into your production line.

Benefits

- Ensures precise dosing, enhancing product quality and consistency.

- Streamlines operations with integrated data acquisition and batch traceability.

- Reduces energy consumption through optimized dosing control.

- Facilitates quick changeovers with easy cleaning and maintenance design.

- Customizable to meet specific industrial and environmental standards.

- Applications

- Paper products, Home care products, Chemicals, Varnishes, Animal feed, Construction materials, Building materials, Automotive components, Wood-based panels, Plastics, Resins, Food products, Paints, Pharmaceuticals, Personal care products, Adhesives, Environmental engineering products, Insulation material, Textiles

- End products

- Cardboard boxes, Acrylic paints, Gloss varnishes, Protein bars, Polymers, Phenolic resins, Wall panels, Concrete additives, Livestock feed, Water treatment chemicals, Plywood boards, Synthetic fibers, Moisturizing creams, Car dashboards, Fiberglass insulation, Detergent gels, Paracetamol tablets, Epoxy adhesives, Polyethylene films

- Steps before

- Storage, Conveying, Delivery, Purification, Heating

- Steps after

- Batch traceability, Process water treatment, Cooling, Packing, Filtration

- Input ingredients

- raw materials, liquid media, solids content, bulk materials, explosive liquids, explosive solids, powdery substances, dry polyelectrolytes

- Output ingredients

- building materials, chemicals, resins, adhesives, finished products, solution from dry polyelectrolytes

- Market info

- IFA Technology is known for specializing in industrial metering and mixing technology, providing engineered-to-order equipment for precise material handling and processing, with a reputation for innovation, reliability, and tailor-made solutions.

- Gravimetric Dosing Principle

- Load cells, weighing cells

- Volumetric Dosing Method

- Flow measurement technology, dosing pumps

- Explosion-proof Compliance

- ATEX Directive 2014/34/EU

- Reactor Temperature Control

- Exothermic/endothermic reactions

- Heating Medium

- Water, air, oils

- Cooling Circuit

- Open/semi-open/closed

- Microdosing Accuracy

- Highest accuracy

- Powder Wetting Mixing Principle

- Rotor-stator

- Batch Traceability

- Data acquisition

- Automation

- PLC-controlled

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Integrated steps

- Weighing, Mixing, Dosing

- Process control

- PLC, visualisation system

- Recipe control

- Automated with batch tracing

- Explosion-proof operation

- ATEX Directive compliance

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Yes/No

- Viscosity

- Varies

- Explosive potential

- Regulated (ATEX)

- Foaming

- Yes/No

- Abrasiveness

- Yes/No

- Container size and shape

- Flexible

- Batch operation

- Yes

- Inline operation

- Yes

- Powder dispersion

- Agglomerate-free

- Material state

- Solid/Liquid

- Corrosive resistance

- Yes/No

- Automation level

- High/Low

- ATEX certification

- Directive 2014/34/EU

- Explosion protection compliance

- Primary and secondary measures

- Custom Acceptance Tests

- By notified body

- Machine footprint

- Compact / Customizable

- Tank shape

- Cylindrical / Conical

- Tank size

- Variable

- Feed method

- Automatic / Manual

- Discharge method

- Gravity / Pump-assisted

- Control panel type

- HMI / PLC / Touchscreen

- Integration possibilities

- ERP / MES / SCADA

- Explosion-proof options

- ATEX certified systems

- System configuration

- Batch / Inline / Custom Design

- Material type adaptability

- Liquid / Solid / Powder

- Reactors

- Manual / Automatic

- Agitator type

- Custom Agitator Design

- Heating and cooling technology

- Water / Air / Oil systems

- Microdosing systems

- Custom Dosing Parameters

- Flocculent systems

- Stationary / Container Solutions