Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with this compact plate evaporator, ideal for handling temperature-sensitive and viscous liquids under challenging evaporation conditions.

Concentrates and Separates Liquid Products

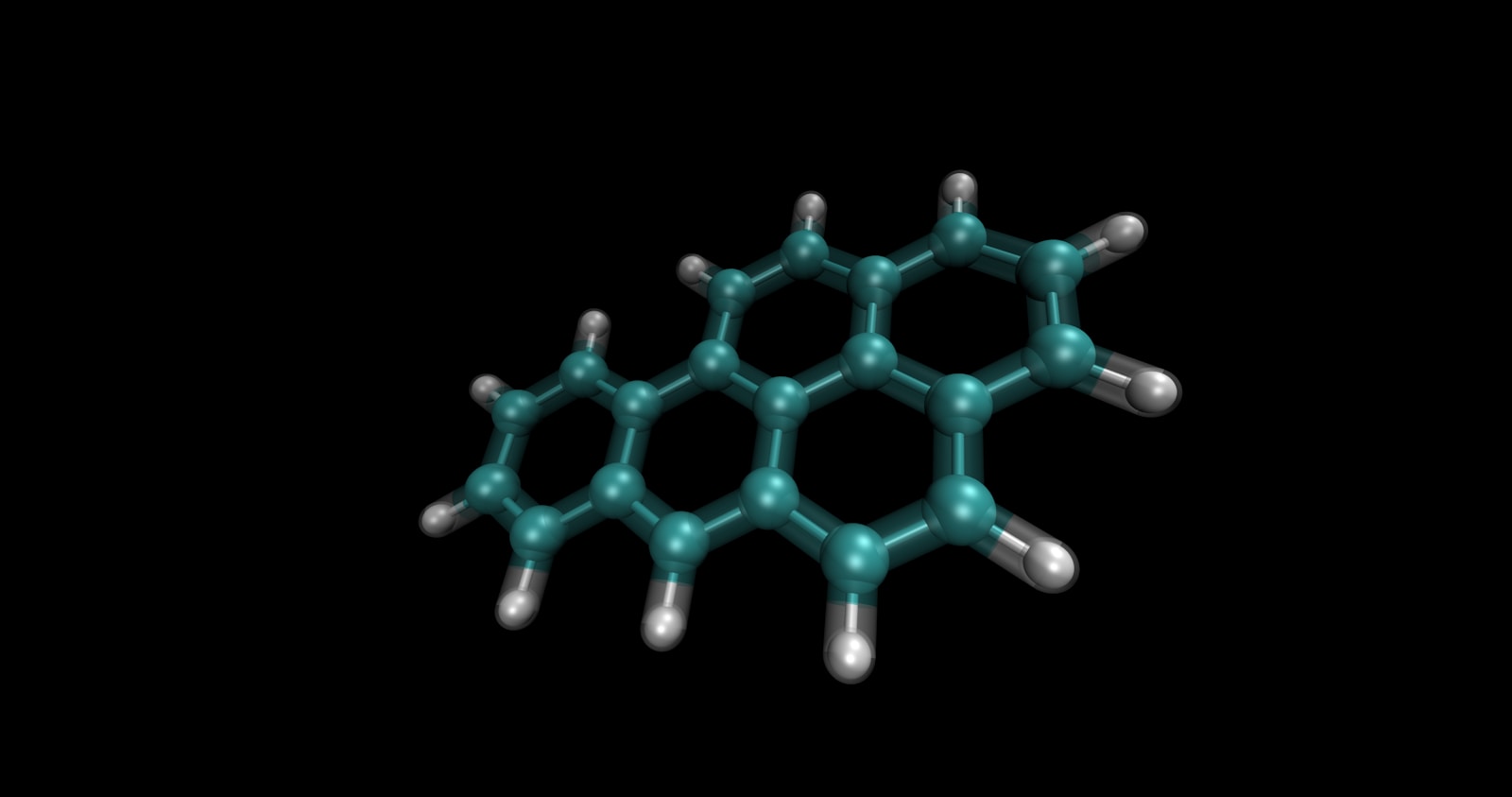

The Plate Evaporator from GEA is designed for the precise concentration and separation of liquid products in various industries, including food, pharmaceutical, and chemical sectors. This equipment utilizes specialized plate heat exchangers with alternating product and heating channels, enhancing efficient heat transfer and evaporation. Its compact, modular design allows for easy integration into existing production lines and is particularly effective for handling temperature-sensitive liquids, such as fruit concentrates and milk powders.

Capable of operating continuously, the Plate Evaporator processes liquids with low solid content, using a rising film technique to drive both the vapor and residual liquid through the system. The downstream centrifugal separator ensures effective separation of concentrated liquids from vapors. With heating versatility, it can utilize both hot water and steam, making it adaptable to various energy sources while maintaining gentle evaporation conditions.

Designed for reduced installation space, the unit’s 4 to 6-meter height is ideal for facilities with spatial constraints. It features a gasket system with easy tool-free removal, enhancing maintenance efficiency. The evaporator’s modular construction allows for scalability by simply adding or removing plates, providing flexible throughput capacities.

Constructed with high-grade materials to ensure corrosion resistance, the Plate Evaporator meets industry standards and certifications for food and pharmaceutical applications. With options for customization and support from GEA’s engineering team, clients can tailor the system to meet specific process requirements, enhancing both productivity and product quality.

Benefits

- Enhances product quality by ensuring gentle, uniform evaporation for heat-sensitive materials.

- Saves valuable floor space with its compact design and modular configuration.

- Offers flexible production scaling by easily adjusting the number of heat exchange plates.

- Minimizes maintenance time with tool-free gasket removal and cleaning.

- Adapts to various energy sources, optimizing resource use and reducing operational costs.

- Applications

- Food, Personal care, Environmental, Marine, Gas, Nutraceuticals, Beverage, Oil, Chemical, Novel foods, Dairy, Pharmaceutical

- End products

- Algae extracts, Bioactive compounds, Pharmaceutical emulsions, Flavor concentrates, Plant-based protein extracts, Fish oils, Cosmetic serums, Chemical solvents, Fruit concentrates, Milk powders, Vegetable extracts, Liquid supplements, Essential oils

- Steps before

- Pre-heating, Mixing, Filtration

- Steps after

- Concentration, Centrifugal separation, Packaging

- Input ingredients

- temperature-sensitive products, viscous products, liquids with small amounts of undissolved solids, low tendency to form incrustations

- Output ingredients

- concentrated liquid, vapors, residual liquid

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Compact design

- Yes

- Overall height

- 4–6 meters

- Evaporation rate

- Low to medium

- Tender to form incrustations

- Low

- Heating media

- Hot water and steam

- Sealing method

- Gasket, no adhesives needed

- Counterflow operation

- Yes

- Space requirement

- Minimal

- Installation

- Quick and easy

- Evaporation conditions

- Extreme

- Working Mechanism

- Plate-and-frame configuration with special plates

- Operating Mode

- Single-pass operation

- Compact Design

- Overall height between 4 and 6 meters

- Heating Media Flexibility

- Can use both hot water and steam

- Evaporation Capacity

- Low to medium evaporation rates

- Installation

- Pre-assembled, easy to transport, quick to install

- Automation Level

- Not specified

- Plate Insertion and Removal

- No special tools required

- Separation Method

- Centrifugal separator downstream

- Flexibility in Evaporation Rates

- Add or remove plates

- Turbulence Generation

- Defined plate distances and specially shaped plates

- Space Requirement

- Little space required

- Compact footprint

- Low overall height (4-6 meters)

- Design

- Plate-and-frame configuration

- Height

- 4–6 meters

- Space requirements

- Little space due to compact design

- Integration

- Quick and easy installation

- Installation

- Pre-assembled construction units

- Evaporation system

- Plate evaporator with alternate product and heating channels

- Plate design

- Special plates with gaskets

- Discharge method

- Downstream centrifugal separator

- Heating media type

- Hot water / Steam

- Plate geometry

- Specially shaped plates

- Gasket type

- Adhesive-free, removable without tools

- Evaporation rate flexibility

- Add or remove plates