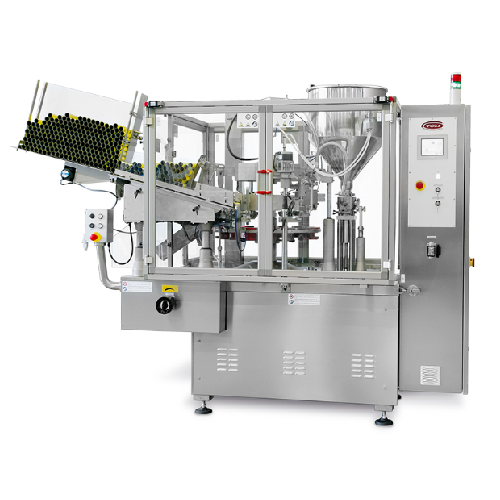

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robust solution that seamlessly fills and seals various tube materials, ensuring precise dosage and secure closure for a wide range of liquid products.

Fills and Closes Tubes Efficiently

The B600 Automatic Tube Filling Machine from TGM is engineered for seamless integration into medium to high volume production lines. It excels at filling and closing both metal and plastic tubes, making it ideal for industries such as pharmaceuticals, cosmetics, and food production. With a throughput of up to 5000 tubes per hour, it maximizes efficiency while maintaining precision. The machine supports a wide range of diameters (10-50 mm for plastic and 10-42 mm for metal) and tube lengths (50-240 mm), providing flexibility for various end-products like toothpaste, medicinal ointments, or silicone sealants. Automated controls and optional fittings enhance its adaptability, while its robust build ensures reliability across different working conditions. Fully compliant with industry standards, it can be configured to meet specific production requirements.

Benefits

- Enhances production efficiency by filling up to 5000 tubes per hour.

- Accommodates diverse product lines with flexible size adjustments for tubes.

- Lowers operating costs through automated filling and closing processes.

- Ensures product quality with precise filling for consistent end-product standards.

- Integrates smoothly into existing lines, optimizing workflow and minimizing downtime.

- Applications

- Personal care products, Toiletries, Household products, Industrial applications, Cosmetics, Food products, Pharmaceuticals

- End products

- Ketchup, Mustard, Silicone sealants, Toothpaste, Adhesives, Medicinal ointments, Shampoo, Cleaning gels, Moisturizing cream, Foundation cream

- Steps before

- Emulsification, Tube Preparation

- Steps after

- Cartoning, Bundling, Case Packing

- Input ingredients

- metal tubes, plastic tubes

- Output ingredients

- filled metal tubes, filled plastic tubes

- Market info

- TGM - TECNOMACHINES srl is known for manufacturing customized, engineered-to-order packaging machinery, specializing in designing and producing high-quality, efficient equipment tailored to specific customer needs in various industries.

- Speed

- Up to 5000 Tubes/Hour

- Tube Diameter - Metal

- 10 - 42 mm

- Tube Diameter - Plastic

- 10 - 50 mm

- Tube Length - Metal

- 50 - 240 mm

- Tube Length - Plastic

- 50 - 240 mm

- Material Handling

- Metal and Plastic Tubes

- Automation

- Automatic

- Production Capacity

- Up to 5000 Tubes/Hour

- Tube Material Compatibility

- Metal and Plastic Tubes

- Tube Diameter Range

- Metal

- Tube Length Range

- 50 - 240 mm

- Automation Level

- Automatic

- Sturdiness

- Solid and Robust Build

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size range

- 10 - 50 mm diameter, 50 - 240 mm length

- Container material

- Metal / Plastic

- Filling speed

- Up to 5000 tubes/hour

- Environment adaptability

- Resistance to various working conditions

- CE marking

- Yes

- GMP Compliance

- Yes

- FDA materials

- Yes

- Discharge method

- Automatic

- Control panel type

- Digital

- Tube diameter range

- 10 - 50 mm

- Tube length range

- 50 - 240 mm

- Control panel type

- Touchscreen HMI

- Material compatibility

- Metal and plastic tubes

- Integration possibilities

- Industry 4.0 ready

- Filling heads

- Customizable for different tube sizes