Wastewater treatment system for industrial applications

Optimize resource management and environmental impact by integrating advanced wastewater treatment solutions, enhancing efficiency in diverse industrial processes and enabling sustainable production practices.

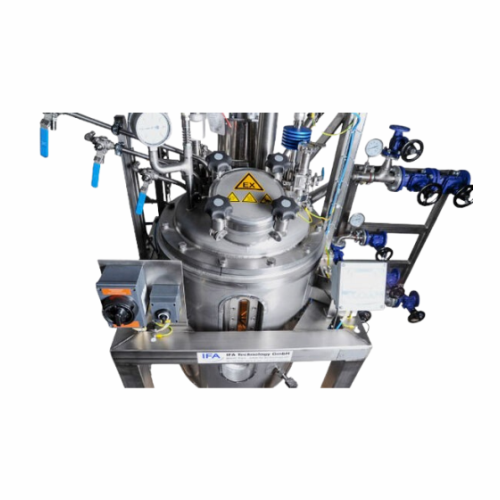

Integrates Weighing, Dosing, and Mixing Operations

The state-of-the-art Weighing and Dosing System from IFA Technology provides tailored solutions for precise control over solid and liquid materials. This system excels in the integration of gravimetric and volumetric dosing paired with advanced mixing capabilities, ensuring versatility across industries such as automotive, construction materials, and pharmaceuticals. It supports a wide range of applications, including creating car dashboards, concrete mixtures, and face creams.

Featuring a PLC-controlled interface for seamless process automation, it allows remote monitoring and adjustments, significantly reducing human error and enhancing production accuracy. Capable of handling substances across various states—solid, liquid, and powder—the system is built with durable material options like stainless steel to withstand corrosion and ensure longevity.

With a focus on sustainability, it is designed to optimize energy consumption, leveraging variable-speed motors that cut energy use by 15%. Its robust construction complies with industry standards, ensuring compliance with relevant certifications. Additionally, the system is equipped with easy-to-use CIP systems, facilitating quick, efficient cleaning that minimizes downtime. Tailored to customer requirements, it offers configurable options for throughput and dosing precision, supported by IFA Technology’s dedicated engineering team.

Benefits

- Enhances production accuracy with precise gravimetric and volumetric dosing.

- Integrates seamlessly into existing lines, reducing setup time and operational inefficiencies.

- Lowers energy usage by 15% with optimized motor control, contributing to sustainability goals.

- Minimizes downtime through efficient CIP systems, boosting overall throughput.

- Offers versatile applications across diverse industries, supporting varied end-product manufacturing.

- Applications

- Food, Home care, Chemistry, Animal feed, Personal care, Construction materials, Pharmaceutics, Automotive, Paint and varnish, Mechanical engineering, Wood-based panels, Environmental engineering, Insulation material, Plastics, Paper, Textiles

- End products

- Polyurethane foam, Car dashboards, Polystyrene sheets, Face creams, Cellulose pulp, Liquid detergents, Cereal coatings, Tablet coatings, Fabric dyeing solutions, Acrylic paint, Wastewater treatment chemicals, Hydraulic system components, Particleboard panels, Industrial adhesives, Concrete mixtures, Livestock feed supplements

- Steps before

- Storage, Conveying, Weighing, Purification, Bag Emptiers

- Steps after

- Product Reject Reduction, Packaging, Energy Savings, Process Water Treatment, Wastewater Treatment

- Input ingredients

- solids, liquids, raw materials, wastewater, energy, compressed air, electricity

- Output ingredients

- processed liquids, processed solids, cleaned water, reduced product rejects, sustainable energy usage

- Market info

- IFA Technology is known for specializing in industrial metering and mixing technology, providing engineered-to-order equipment for precise material handling and processing, with a reputation for innovation, reliability, and tailor-made solutions.

- Automation

- PLC-controlled

- Dosing type

- Gravimetric / Volumetric

- Explosion-proof Systems

- Available

- Batching Plants

- Customised

- Heating and Cooling Technology

- Integrated

- Viscosity Control Systems

- Available

- Flow rate

- Customizable

- Feed rate

- Customizable

- Cleaning method

- CIP / manual

- Working Mechanism

- Batch Processing / Continuous Flow

- Integrated Steps

- Weighing, Mixing, Dosing

- Automation Level

- Manual / PLC / SCADA

- Batch vs. Continuous Operation

- Batch / Inline Continuous

- Energy Efficiency

- Optimized for Low Consumption

- CIP/SIP

- CIP 121°C / SIP 135°C

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape and size

- Custom sizes

- Footprint

- Customizable

- Control panel type

- PLC / Manual

- Discharge method

- IBC / Bag / Drum

- Control panel type

- PLC / HMI / SCADA

- Integration possibilities

- ERP / Database Systems

- Smart IFA

- Process Automation

- Visualisation

- Graphical User Interface

- Recipe Control

- Automated / Manual

- Data Base Systems,Batch Tracing and ERP Connection

- Available