Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal during mixing. But combining powders into the liquid phase could form clumps, producing poor dispersal and uneven viscosities. To overcome this challenge, manufacturers typically resort to additional equipment, such as recirculating pumps, to process the solution again.

Mixing fine solids with liquid and pumping out homogeneous mixtures

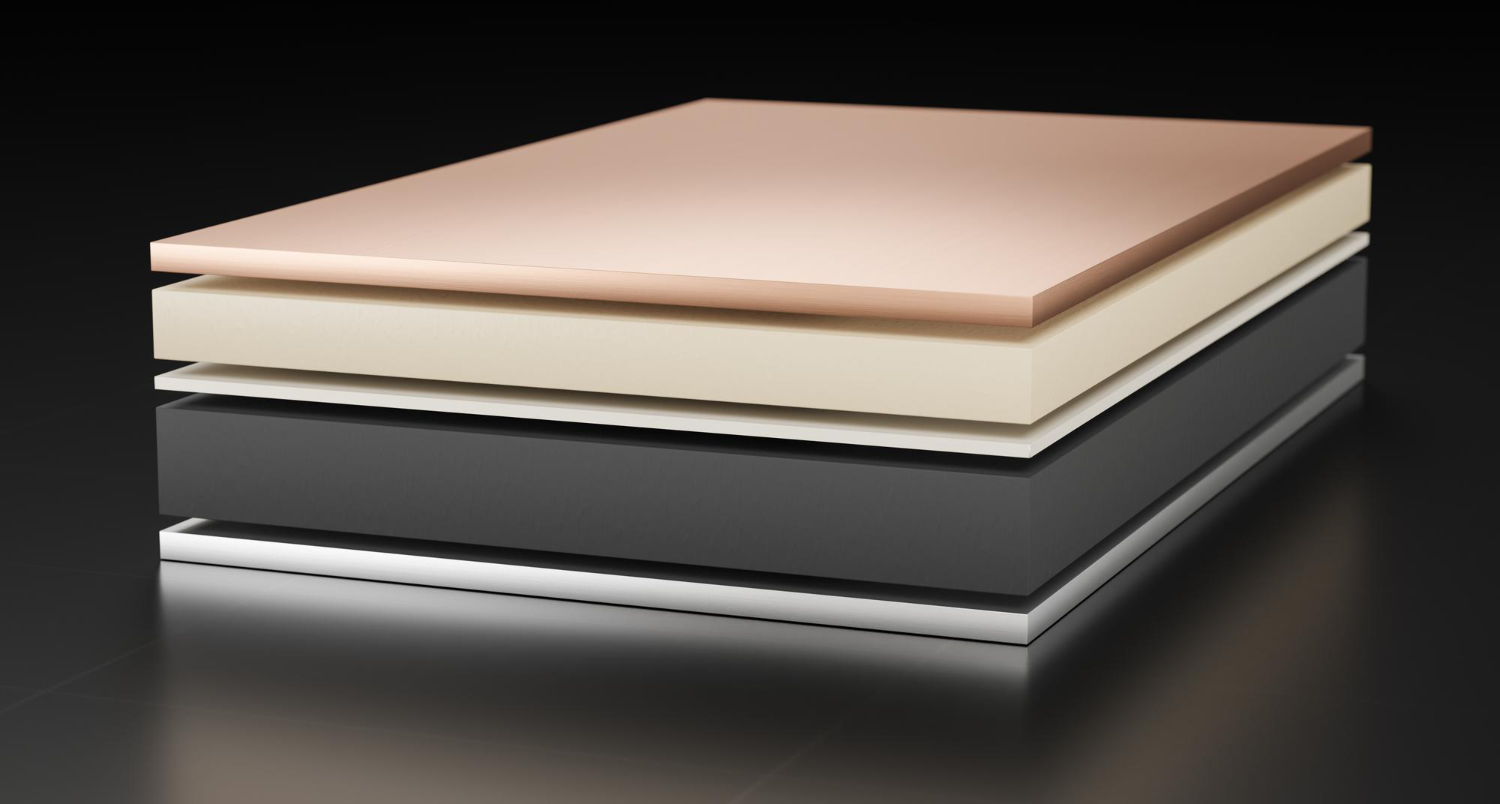

The Compact Mixing Plant (XPP) from IKA applies a two-stage mixing technique that prevents clumping and produces homogeneous dispersal of the powders. Using high-shear forces, the system mixes fine solids with liquids for paints, coatings, lacquers, adhesives, and other highly viscous products.

The combined solution is recirculated back into the main vessel without external pumps and remixed until the desired viscosity is achieved. The XPP integrates a stirrer into its compact design to ensure a constant throughput even at high viscosity levels.

Combining the mixing and pumping capabilities into one solution, the Compact Mixing Plant simplifies the process and reduces the footprint for large batch production.

Benefits

- Wide capacity range (50 to 4000 liters)

- No additional pumps required for discharge

- Capable of mixing high-viscosity substances

- ATEX and/or GMP-compliant design

- Optional additional vessels