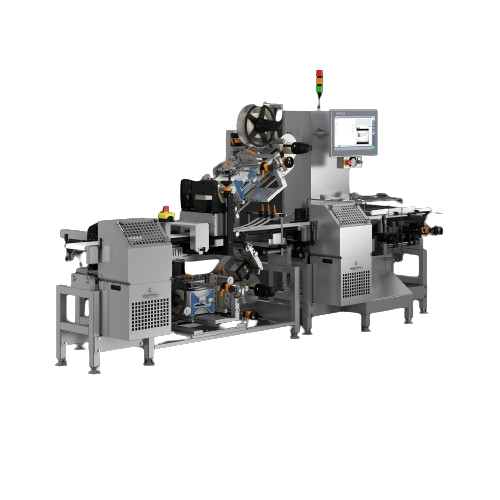

Modular end-of-line system for quality control

Streamline your end-of-line operations with seamless integration of weighing, labeling, marking, verification, and inspection processes, ensuring 100% quality assurance before products leave the facility.

Integrates and Optimizes End-of-Line Packaging Tasks

The Modular End-of-Line System offers a comprehensive integration of weighing, labeling, marking, verification, and inspection processes. Designed for continuous, high-speed operations, this system addresses the complex needs of food, pharmaceutical, and cosmetic manufacturers, among others. Its modularity allows seamless adaptation to various packaging formats, ensuring 100% product verification in industries ranging from building materials to logistics. Capable of handling solid, liquid, powder, and granular products, it supports efficient energy usage with options for advanced material compatibility, ensuring durability in demanding environments. The system’s PLC control and compatibility with remote monitoring facilitate easy integration into existing production lines, while compliance with industry standards ensures reliability and safety.

Benefits

- Enhances production efficiency by integrating multiple processes in one system.

- Minimizes production errors with 100% product verification.

- Offers flexibility to accommodate various product types and packaging formats.

- Reduces energy usage with efficient operational controls.

- Facilitates compliance with industry standards, ensuring product safety and quality.

- Applications

- Food, Aerosol products, Technical products, Mineral compounds, Mail, Building materials, Chemical products, Cosmetics, Logistics, Pharmaceuticals

- End products

- Cement bags, Blister-packed tablets, Packaged ready-to-eat meals, Electrical components, Postage bags, Delivery parcels, Industrial adhesives, Skincare creams, Packaged gravel, Spray deodorants

- Steps before

- Filling, Primary Packaging

- Steps after

- Product Verification, Final Packaging, Quality Control

- Input ingredients

- various product dimensions, packaging types, products for marking, products for verifying, products for labeling, products for weighing, products for metal detection, items post-filler

- Output ingredients

- 100% verified products

- Market info

- Wipotec is renowned for its precision weighing technology and high-speed checkweighers used in various industries, including pharmaceuticals and food. They are recognized for their innovation and high-quality engineered-to-order solutions in weight measurement and inspection systems.

- Integration capabilities

- Marking, labeling, weighing, metal detection

- Modularity

- Full integration of functions

- Product adaptability

- Adjustable to most product dimensions and packaging types

- Verification accuracy

- 100% verified products

- Control system

- Central control

- Automation level

- Simple and safe operation

- Modular integration

- Yes

- Automation level

- PLC

- Batch vs. continuous operation

- Inline

- Cleaning method

- Effortless / Manual

- Flexibility in handling modules

- Adjustable to various product dimensions and packaging types

- Control system

- Centralized control for all modules

- Energy efficiency

- Optimized for lower energy consumption

- Upgradeability

- Upgradeable to full serialization

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Various sizes

- Packaging type

- Flexible

- Material handling compatibility

- Adjustable modules

- Verification needs

- 100% product verification

- Product dimension compatibility

- Adjusts to most sizes

- Modular design

- Yes

- Footprint

- Customizable

- Handling modules

- Adjustable to product dimensions

- Integration

- Marking, Labeling, Weighing, Metal Detection

- Control panel type

- Centralized

- Control panel type

- Central control interface

- Integration possibilities

- Marking, labeling, weighing, metal detection

- Modular design

- Yes

- Product handling adjustments

- Adjustable to product dimensions and packaging types

- Upgrade options

- Upgradeable to full serialization