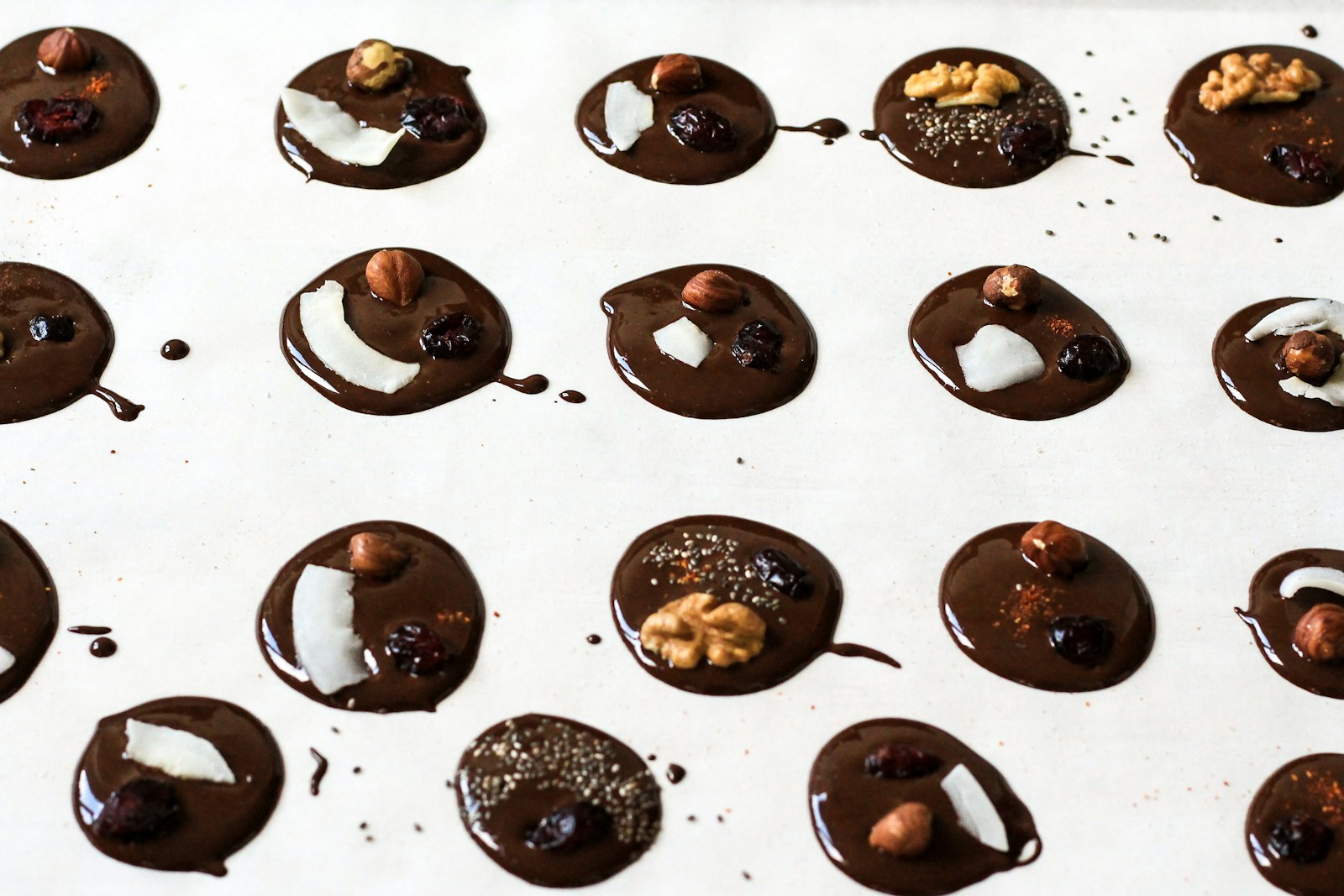

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delivering high-quality chocolate drops and filled treats seamlessly into your production line.

Deposits and Moulds Chocolate Drops and Chips

The Chocolate Drop Production Line, model MKDL-100, from Memak Professional Chocolate and Bakery Machines is engineered to meet the needs of confectionery and bakery producers seeking efficient and consistent chocolate production. This system includes both single and double depositor configurations, allowing you to tailor production based on demand. It utilizes a precise depositing mechanism that streamlines the process of creating chocolate drops, chips, and filled chocolates. Capable of reaching a throughput of up to 350 kg per hour, this line offers high-speed, automated operations to optimize your processing efficiency.

Designed for seamless integration into existing production environments, it accommodates both continuous and batch operations. Its PLC-controlled system ensures precise application and easy remote monitoring, reducing manual oversight. The equipment supports a wide range of end-products, including nougat and cereal bars, making it versatile for various sweet goods applications.

Energy efficiency is enhanced by optimized motor controls, minimizing power consumption while maintaining high production rates. Constructed with durable stainless steel for improved hygiene and corrosion resistance, it stands up to rigorous use. The line is equipped with a clean-in-place (CIP) system for ease of maintenance, promoting a swift transition between production cycles. Customization options are available to suit specific production needs, ensuring that the equipment not only meets but exceeds your performance expectations.

Benefits

- Enhances production speed and consistency with dual depositor options.

- Lowers operational costs with energy-efficient motor controls.

- Minimizes manual intervention through automated PLC controls, reducing labor requirements.

- Ensures product quality and hygiene with corrosion-resistant stainless steel construction.

- Simplifies maintenance and extends equipment lifespan with an integrated clean-in-place system.

- Applications

- Chocolate, Sweets, Confectionery, Bakery

- End products

- Chocolate shells, Nougat bars, Filled chocolates, Soft candies, Cereal bars, Chocolate chips, Chocolate drops

- Steps before

- Fat Melting, Pre-Mixing, Storage, Chocolate Processing

- Steps after

- Cooling, Moulding, Chocolate Wrapping, Packing

- Input ingredients

- chocolate mass, ingredients for chocolate drops

- Output ingredients

- chocolate drops, coated chocolate, one-shot chocolate products

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Chocolate Drop Weight

- 0.1 g to 3 g

- Depositor Options

- Single / Double

- Production Capacity

- 12-15 shots/min up to 350 kg/h

- Total Power

- 18 kW

- Batch vs. continuous operation

- Batch

- Automation level

- PLC

- Cleaning method

- Manual

- Feed type

- Single / Double Depositor

- Chocolate drop weight

- 0.1 g - 3 g

- Number of depositors

- Single / Double

- Control panel type

- Touchscreen

- Depositor type

- One shot

- Capacity range customization

- 0.1 g to 3 g