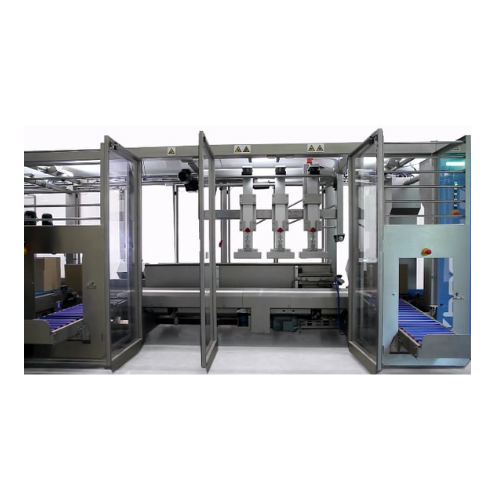

Full Rsc case shaker-compactor-sealer

Streamline your packaging line with a solution that compacts and seals cases to eliminate product damage during transport, ensuring your goods arrive intact and ready for the shelf.

Compacts, Seals, and Settles Products Efficiently

The Shaker-Compactor-Sealer (SCS) from BluePrint Automation is a revolutionary solution for efficiently managing post-packing processes in industries like dry food, frozen goods, and pet food. By integrating vibratory settling and sealing into one function, the SCS ensures products such as cereal bars and potato chips are securely compacted and ready for transport. Utilizing a patented Oval Roller, it vibrates to settle contents while transporting cases for seamless sealing. This compact design improves cleanability and reduces maintenance by eliminating traditional conveyor belts. Suitable for high-speed, fully automated operations, the SCS supports continuous production with laser monitoring to detect and reject any imperfect cases. Capable of adapting to varying case sizes through automatic adjustments, it assures optimal pressure application to minimize product damage. The SCS’s open structure allows easy access for maintenance, while its modular design ensures smooth integration into existing production lines, providing robust solutions to common packaging challenges.

Benefits

- Ensures product stability during transport by eliminating empty pockets through vibratory compacting.

- Reduces maintenance needs and enhances hygiene with an open design devoid of conveyor belts.

- Facilitates seamless production adaptability with automated size adjustments for various case dimensions.

- Minimizes product damage and maximizes throughput with optimal pressure application and quick settling.

- Increases operational efficiency with a compact, space-saving design suitable for high-speed, continuous processes.

- Applications

- Frozen, Snacks, Pet food, Protein, Dryfood

- End products

- Frozen vegetables, Kibble, Cereal bars, Potato chips, Protein bars

- Steps before

- Packing, Product Settling

- Steps after

- Sealing, Shipping

- Input ingredients

- non-rigid products, secondary casing, individual items, secondary container

- Output ingredients

- compacted cases, sealed cases, retail ready packaging, shelf-ready tray

- Market info

- BluePrint Automation is known for designing and manufacturing innovative packaging automation systems, specializing in end-of-line robotic case packing solutions for various industries, enhancing operational efficiency and product handling with a strong reputation for quality and innovation.

- Automation

- Fully Automated

- Compacting method

- Vibratory movements

- Compacting equipment

- Oval Roller

- Case sealing

- Tape or hot melt sealing

- Laser level measurement

- Included

- Changeover capability

- Automated self-adjustment

- Cleanability

- Improved open design

- Control system

- Central backbone integration

- Sealing efficiency

- High

- Compacting efficiency

- Unparalleled consistency

- Working mechanism

- Vibratory compacting

- Integrated steps

- Compacting and sealing

- Batch vs. continuous operation

- Batch

- Automation level

- Fully automated

- Changeover time

- Automated adjustment

- Cleaning method

- Improved cleanability

- Energy efficiency

- Integrated design

- Product settling control

- Laser measurement

- Product rejection

- Laser-triggered rejection

- Compact footprint

- Smaller than traditional solutions

- Machine footprint

- Compact design

- Vibratory element

- Patented Oval Roller

- Discharge method

- Oval Roller for settling and transporting

- Control panel type

- Central backbone integration

- Cleanability

- Open design with improved cleanability

- Compression plates

- Servo-driven floating plates

- Control panel type

- Central backbone integrated within frame

- Changeover automation

- Automated size adjustment

- Integration possibilities

- Entire post-packing process automation

- Compact footprint

- Smaller than traditional solutions

- Sealing options

- Tape or hot melt