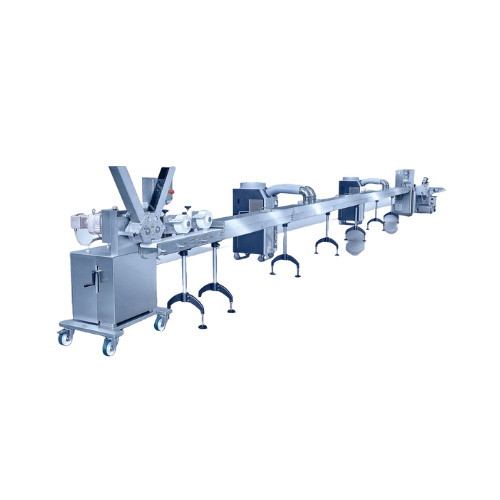

Small-scale cereal bar production system

For nimble snack producers, this system offers versatility by seamlessly integrating mixing, cooling, and cutting processes—perfect for crafting diverse, high-quality cereal bars with minimal space requirements and rapid product changeovers.

Mixes, Cools, and Cuts Cereal Bars

The SnackFix™ Cereal Bar Production Line from Bühler Group is a compact, modular solution designed for small-scale snack manufacturers and bakery businesses. This production line stands out by seamlessly integrating processes—mixing, cooling, and cutting—into a continuous operation that maintains high flexibility and variety in output. Equipped with continuous mixers, cooling tunnels, and cutting systems, the SnackFix™ line can handle up to 130 kg of product per hour. Its modular design facilitates easy swapping of rolls, supporting rapid product changes from granola and nut bars to energy and protein bars. The touch-panel controls allow precise dosing and temperature adjustments, ensuring consistent quality. Crafted from stainless steel, the machine is easy to maintain and clean, featuring quick disassembly for thorough hygiene between production runs. Ideal for those aiming to diversify their product line with minimal footprint, the SnackFix™ supports startups and food producers in scaling operations efficiently.

Benefits

- Enhances production flexibility with quick roll exchange for diverse product types.

- Boosts efficiency by producing up to 130 kg of cereal bars per hour.

- Minimizes cleaning time with stainless steel construction for easy sanitation.

- Offers precision control over production parameters with intuitive touch-panel interface.

- Supports seamless integration into existing lines with a modular, compact design.

- Applications

- Cereal bars, Breakfast cereals, Confectionery, Snacks

- End products

- Muesli bars, Fruit and nut bars, Energy bars, Granola bars, Seed bars, Nut bars, Breakfast squares, Yogurt-coated cereal bars, Chocolate-coated cereal bars, Protein bars

- Steps before

- Grain handling, Dough prep, Extrusion, Mixing

- Steps after

- Cooling, Cutting, Packing, Weighing

- Input ingredients

- cereal blend, binder

- Output ingredients

- cereal bars

- Market info

- Buhler is renowned for manufacturing advanced process solutions for food, feed, and advanced materials. They are highly regarded for their innovation in milling technology and equipment quality.

- Capacity

- Up to 130 kg/h

- Automation

- Touch panel control

- Material Used

- Stainless steel

- Product Changeover

- Easy roll exchange

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- Touch panel control

- Changeover time

- Quick roll exchange

- Easy switch between products

- Modular design

- Cleaning method

- Easily cleanable stainless steel

- Compact solution

- Integrated mixer, cooling tunnel, and cutting system

- Production capacity

- Up to 130 kg per hour

- Cleanability

- Stainless steel construction

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Compact footprint

- Yes

- Control panel type

- Touch panel

- Discharge method

- Transport belt

- Control panel type

- Touch panel

- Integration possibilities

- Modular design

- Product switch flexibility

- Easy roll exchange

- Construction material

- Stainless steel

- Operational control

- Precise control via touch panel