Find Continuous Deep Fry Equipment

And connect directly with leading technology suppliers for your snack production line.

Deep frying in oil gives fried food that unmistakable, rich mouthfeel. The golden liquid adds texture and folds foods into layers of flavor, ready to be released onto our tastebuds. But hot oil is a demanding ingredient, and heating conditions impact its characteristics considerably during cooking.

If you want the best results, then the key to quality deep frying is managing the flow of hot oil through the production process: ensuring a constant fresh supply at a uniform temperature. However, striking a balance between low oil content and short turnover time is easier said than done. Especially in a commercial kitchen or an industrial setting. Avoiding the smoke point is essential when it comes to cooking with a deep fryer.

Oil freshness enhances the deep fry success no matter the absorption rate

Deep fryers develop a fuller palate in food as the oils distribute the concentrations of components that produce taste, like salts and sugars. But not all foods absorb cooking oil at the same rate. Nuts, for example, register a low saturation compared to potato products such as french fries. In all instances, a commercial deep fry cycle that manages low volumes of oil but keeps that quantity clean for longer, helps achieve a higher depth of flavor and texture in food products.

Prevent hot oil contamination by reducing content and accelerating turnover time in the sheet pan

Oil is a delicate substance and can quickly degrade if exposed to other elements for a long time while cooking. Water contact alters the chemical properties and deteriorates its flavoring quality. Additionally, the hydrolytic reaction increases as temperatures and pressures rise.

Oxygen is another element that causes more oil to break down and generate undesirable compounds. In the best-case scenario, these chemicals produce a foul taste in the end product; they could develop into harmful toxins in the worst cases.

A third risk to oil during frying is the agglomeration of traces of compounds at surface level. As these polymers heat up, they start bubbling, which causes endothermic reactions and burning. High quantities of oil with a slow turnover time elevate the dangers of hydrolysis, oxidation, and polymerization. In order to help avoid this, it is important to ensure that the heating element of your deep fryers are at the correct temperature is important to avoid this. It is also very important to make sure that you have your recipes worked out before using deep fry cookers in any commercial kitchen, big or small.

Tell us about your deep-fry production challenge

Are you looking into starting up or improving your frying production line equipment? Tell us about your production challenge. After a quick conversation about your desired snack product and commercial deep fryer production needs, we connect you quickly with a technology partner that best fits your deep frying needs and has experience in making your product.

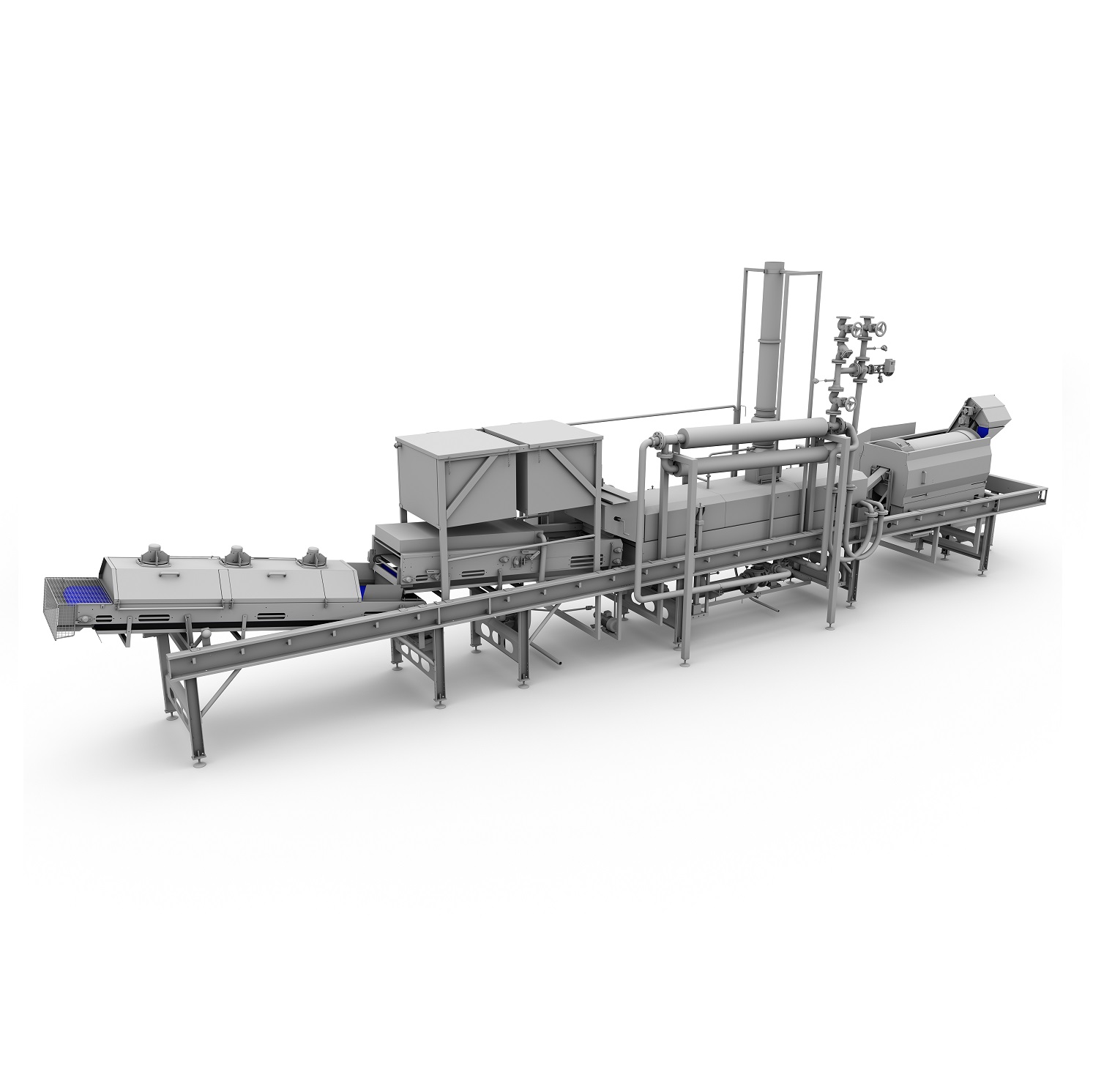

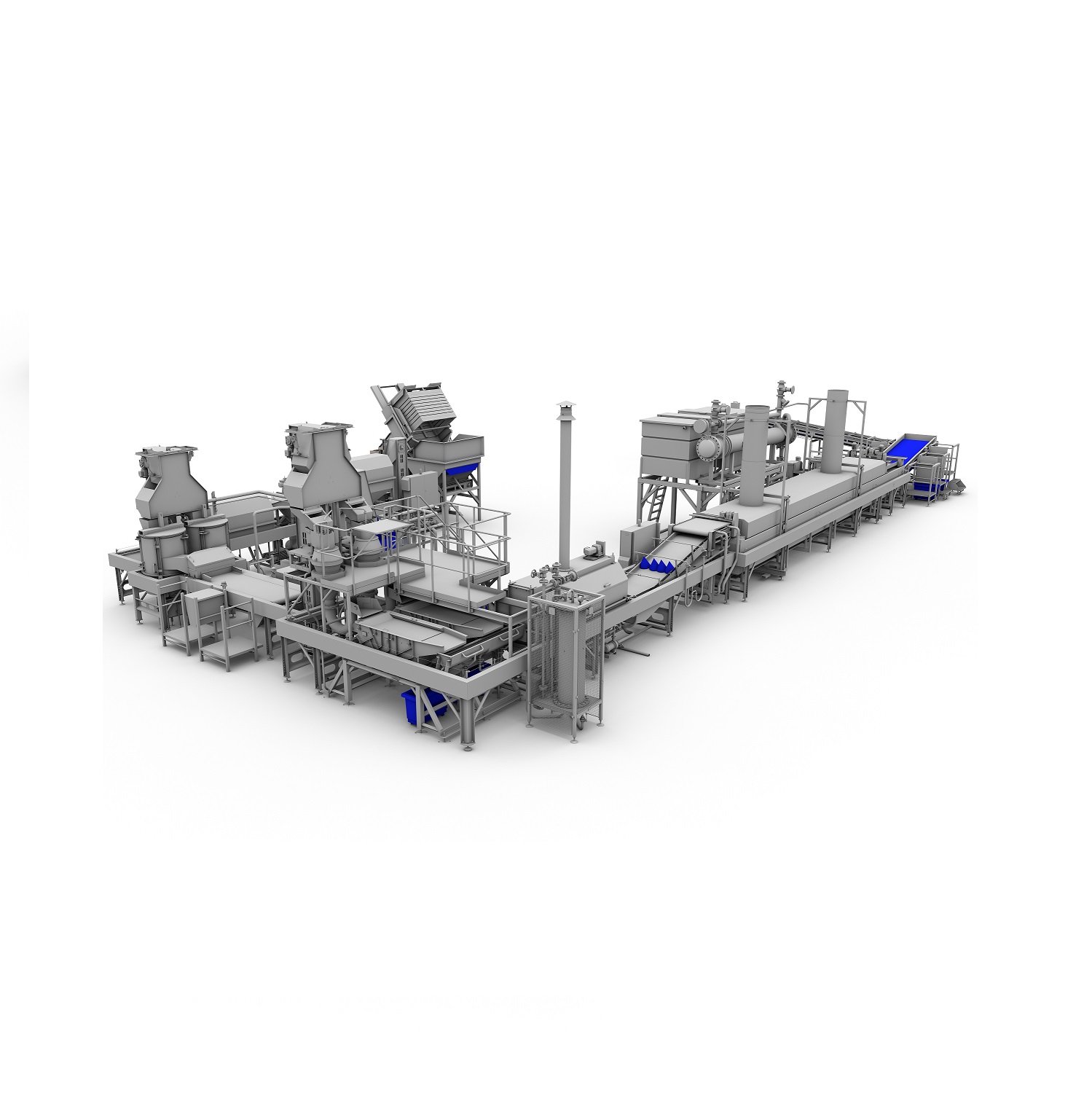

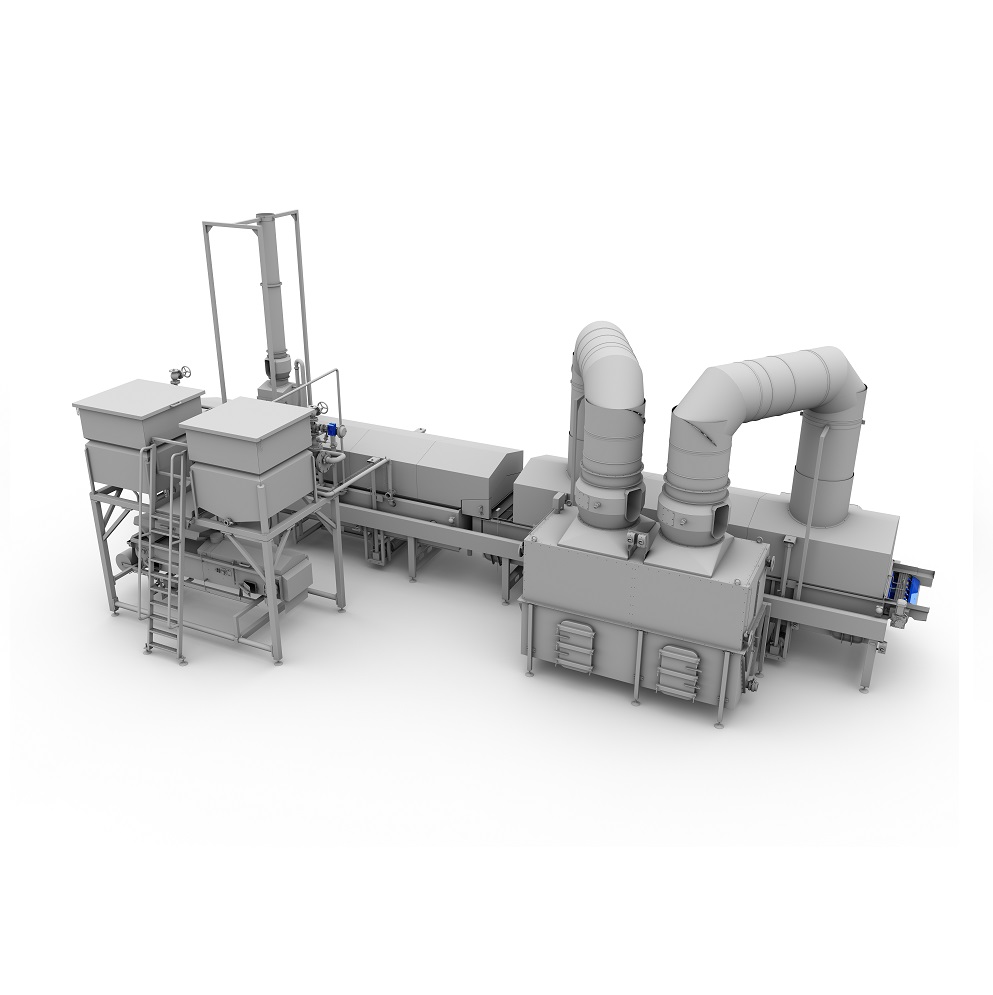

An integrated oil filtration system makes the continuous frying line more efficient

A fryer oil filtration system extends the lifecycle of the raw material. Cooked vegetable oil loses its character as it accumulates compounds in the fryer tank. Passing the used oil through a filter removes the contaminants and refreshes it for further use in fryers.

A paper filter system lets the oil through and traps the external substances. A gas or electric fryer line that incorporates low oil content, a short turnover rate, and a high-quality paper filtration system reduces the costs of raw materials and retains the oil condition for longer when cooking. This is especially useful when making vegetables or french fries- in this way.

It is also worth mentioning the difference between electric and gas fryers. Typically gas fryers will heat up faster than its electric counterparts. For this reason, gas fryers are commonly found in industrial and a commercial kitchen as well as in a restaurant kitchen. If you’re looking to increase the output, then a gas fryer is the best choice. However, if you’re looking for extra mobility then electric fryers, such as countertop deep fryers, are perhaps the best way to go. That is due to the fact that they don’t need to be hooked up to the main gas line. Furthermore, it is also believed that electric deep fryers are better for the environment.

Different fried foods set different temperature parameters for deep fryer equipment.

The frying process is not the same for all food products. Peanuts, for example, typically have a lower absorption rate than other wheat nut snacks.

Cooking temperatures also vary per item. Getting your recipes right is key here. For example, potato chips demand higher temperatures than manufactured chips because the base ingredients are different. Another critical factor in a commercial fryer is the size of the food item. Oil coats the products as they are fried; cooked snacks like cheese balls, onion rings or pork rinds take longer to reach the right texture than pellet snacks.

Continuous frying lines for peanuts demand high oil quality retention

Peanuts are a tricky snack to fry and get right. These legumes require a thorough cleaning to shed the shell and skin. Their oil intake rate is much lower than most other fried products, so they demand a longer fry time. But peanuts are a delicate item, so the oil quality needs to be as high as possible to help lock in the full flavors of each grain.

Moreover, peanut snacks with added coatings such as batters or flavorings increase the risks of deterioration. This is evidenced in batch fryers but particularly in continuous systems. Using techniques like filtration and short turnover time, a rapid refresh rate of oil ensures a superior deep frying quality throughout. Quality retention means there’s no need for the food to sit in paper towels to soak up excess oil after leaving the conveyor belt or fry basket.

New trends in potato chips: change the oil but keep the crunch

Is there a more popular snack than the potato chip? The harvested vegetable is sliced thinly to allow more air and produce a richer taste. The other secret is fresh oil. Using oil give the slices that coarse texture and a brittle structure that makes chips crispy.

Although universally loved, potato chips rank low for nutritional value and healthy food consumption. To address concerns, manufacturers are turning to alternative vegetable oils extracted from olives, avocado, coconuts, and other natural sources.

Reduce excess oil in fried extruded snacks with de-fatting equipment

Pellet snacks are extruded from a range of base ingredients: from wheat to corn to potatoes. But the final taste and consistency of the extrudate are determined by the quality of lipids absorbed during frying.

However, a trend towards reducing fats across the food sector is leading producers to experiment with frying that integrates de-fatting techniques. One technology applies vibrating belts to help get excess fats to drain from the pellets through the conveyor. Products can be conveyed through the de-fatting belt as many times as needed.

Air knives provide an alternative solution by applying air pressure. The relatively high velocity and volume of air pressure blow extra oil off the surface of the food snacks.

Enhance the taste of deep-fried products with industrial food seasoning equipment

Seasoning elevates the palatability of the fried item. But besides giving them a delicious taste, it serves as a sensorial differentiator for food products.

The fried foodstuffs are enveloped in the seasoning powder mix after a light oil coating. This time, oil is sprayed onto the products as they tumble in a rotating drum. The items are then transferred to another rotating drum and sprinkled with the seasoning powder. The tumbling process spreads the layer of seasoning evenly across the surfaces. This requires specialized commercial equipment that can be found in industrial fryer factories as well as in a restaurant or commercial kitchen.

Connect to these experts

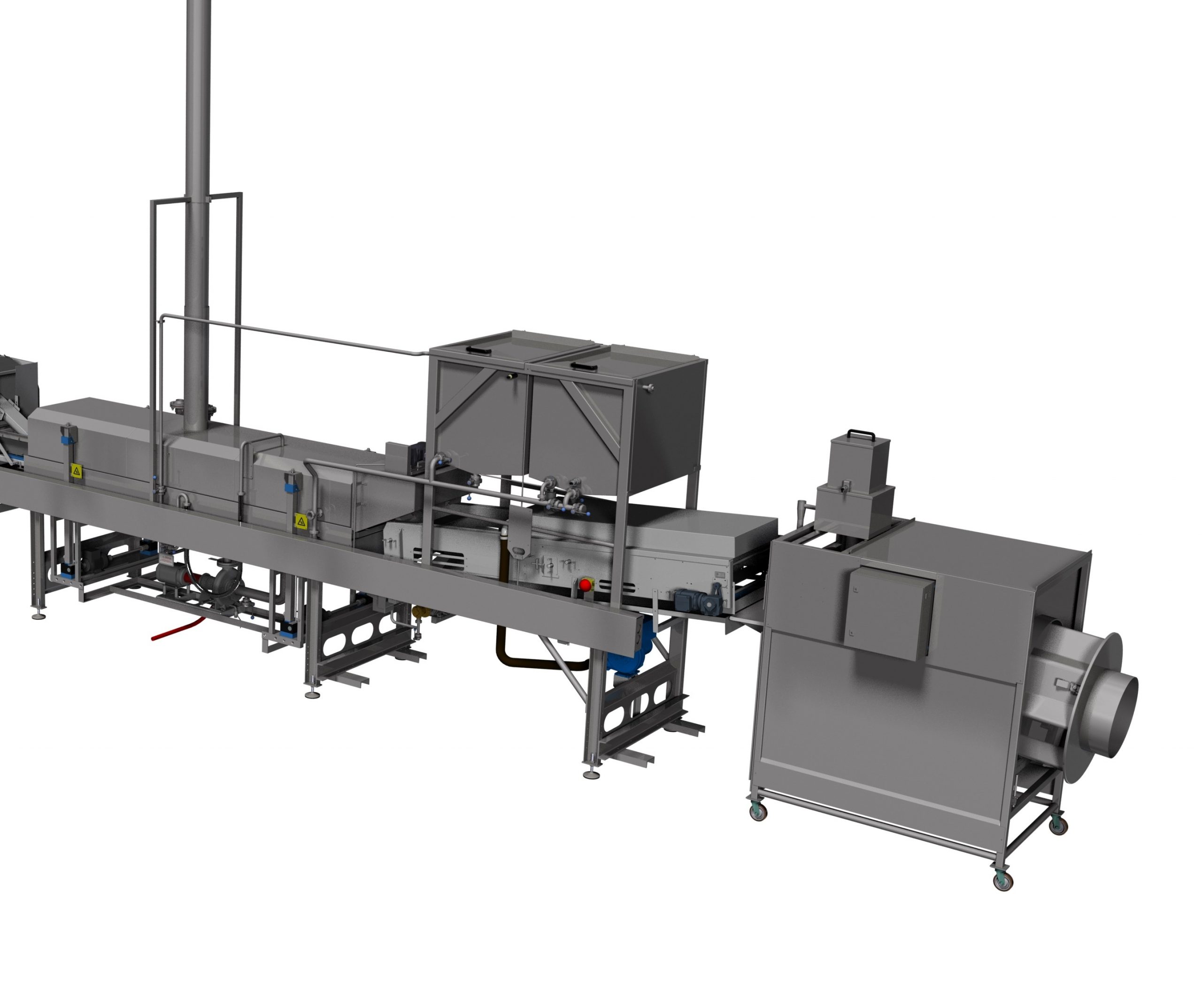

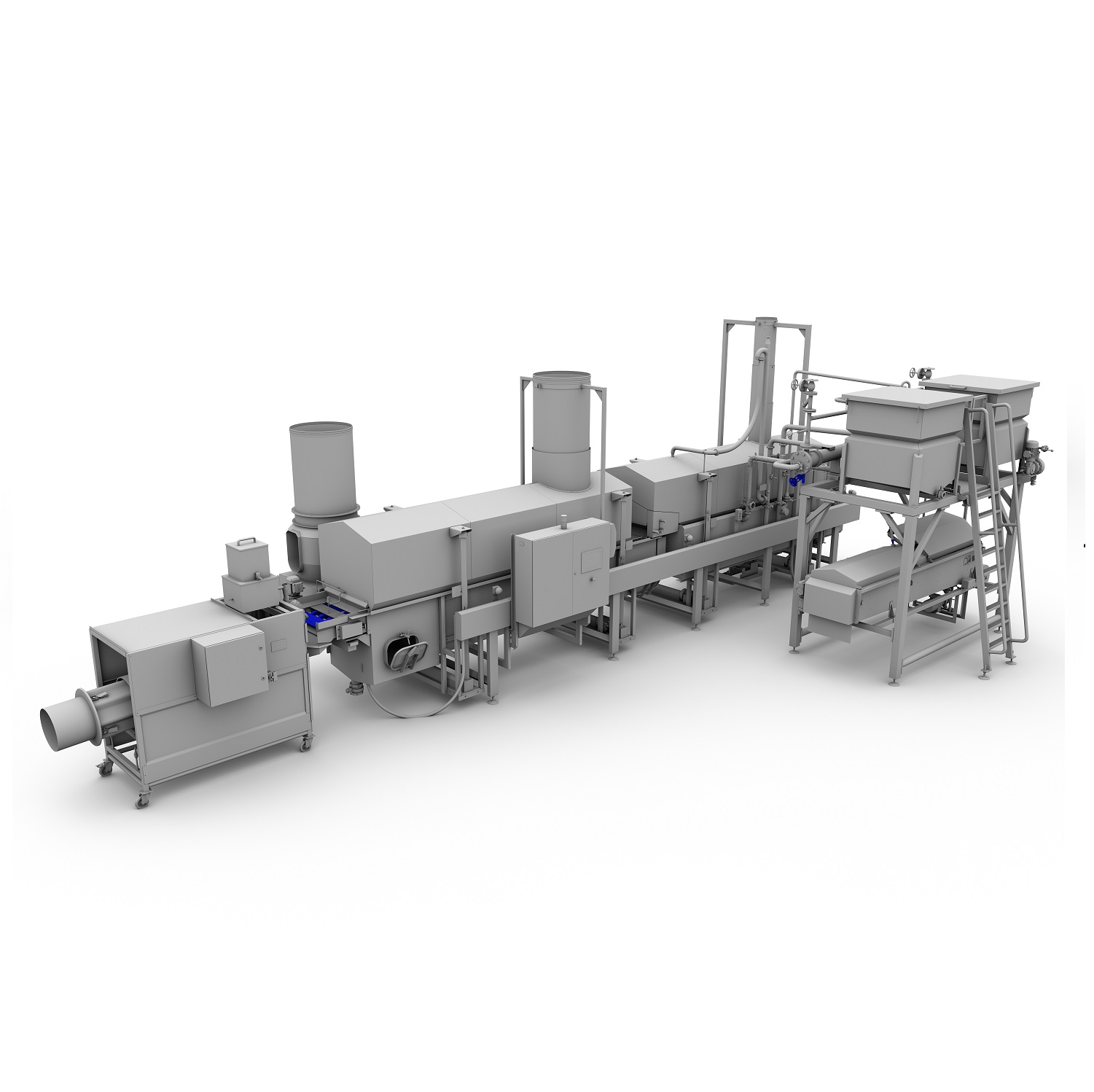

Kuipers Food Processing Machinery is known worldwide for its efficient continuous fryer systems and nut processing lines. They build commercial snack production solutions, supplies and equipment for small starters as well as large multinationals and are famous for their cost-saving efficient solutions. Weather you’re looking for countertop, gas or electric fryers Curious to learn more?

Videos on deep frying production lines

Continuous peanut fryer line

Filling and seaming of cans with snacks

Industrial case packer for potato chip bags

From the fryer pan into the snack bag

The primary challenge of packaging fried foodstuffs is retaining the freshness of the fry. Exposure to air causes a breakdown in the carbon-carbon double bonds of oils. This not only hardens the texture of the items but degrades the taste profile significantly, turning foods rancid.

There are multiple packaging formats for fried foods, but they all seal away the products from oxygen, humidity, and ultraviolet.

Fragile items such as potato chips, battered nuts or pellet snacks are transported into their final containers using suction technology. This ensures gentle handling and accurate dosing. But there are several other packaging solutions for snacks coming from deep fryers. From pouches to cans and lined cartons to oriented polypropylene bags.