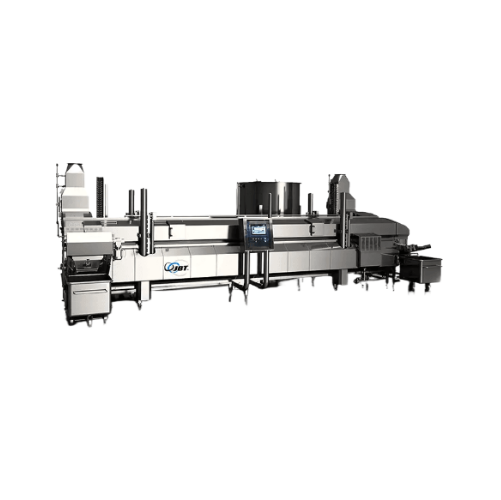

Direct heated immersion fryer for convenience food processing

Achieve superior temperature control and minimize oil consumption with this innovative fryer, designed to enhance product quality while maintaining operational efficiency in high-demand food processing environments.

Immersion Fries and Filters Food Products

The Stein M-Fryer from JBT is a direct heated immersion fryer designed for global food processors seeking superior temperature control and oil management. Its unique design incorporates THERMoFIN technology for gentle heat transfer and reduced oil degradation. This fryer efficiently processes a wide range of applications, including crispy chicken nuggets, tempura prawns, and roasted peanuts, serving industries like poultry, meat, seafood, and ready meals. Available in two frying widths and four lengths, it can be configured with either electric or thermal fluid heating and allows for seamless future upgrades. Features like continuous sediment removal and an internal filtration system maintain high product quality, while CO2 or water mist fire suppression options enhance safety. ProLINK-enabled automation facilitates process control, integrating smoothly into your production line. Crafted for durability and efficiency, the Stein M-Fryer reduces operating costs and ensures consistent product quality, making it a reliable choice for high-demand processing operations.

Benefits

- Enhances product quality through precise temperature control, reducing the risk of oil degradation.

- Maintains high hygiene standards with an integrated sediment removal system and internal filtration.

- Offers operational flexibility with a modular design that accommodates different heating methods.

- Improves production efficiency with continuous, automated operation for high output demand.

- Increases safety with compatible CO2 or water mist fire suppression systems.

- Applications

- Seafood, Ready meals, Meat, Fruits, Nuts, Poultry

- End products

- Fried chicken wings, Shrimp tacos, Sautéed beef strips, Breaded fish fillets, Mushroom risotto, Fried vegetable tempura, Battered onion rings, Tempura prawns, Roasted peanuts, Crispy chicken nuggets

- Steps before

- Portioning, Slicing, Preparation, Injection, Marination

- Steps after

- Coating, Freezing, Chilling, Packing, Labeling

- Input ingredients

- oil, poultry, meat, seafood, fruits, nuts, ready meals

- Output ingredients

- fried poultry, fried meat, fried seafood, fried fruits, fried nuts, cooked ready meals

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Frying width

- Two effective widths

- Frying length

- Four different lengths

- Heating type

- Direct heated, thermal fluid or electric

- Drive type

- Electric or hydraulic

- Fire suppression compatibility

- CO2 or water mist

- Ventilation stack

- Single or double

- Sediment removal

- Continuous

- Internal filter system

- Yes

- Process automation

- ProLINK enabled

- Heating mechanism

- Direct heated immersion

- Oil volume management

- Minimum oil volumes

- Temperature control

- Superior temperature control

- Process flexibility

- High

- Heat transfer

- Gentle Heat Transfer (THERMoFIN technology)

- Sediment management

- Continuous sediment removal

- Automation level

- ProLINK enabled

- Fire suppression compatibility

- CO2 or water mist

- Drive type

- Electric or hydraulic

- Frying width

- Two effective widths available

- Frying length

- Four different lengths available

- Ventilation

- Single or double ventilation stack

- Heating conversion capability

- Switchable from electric to thermal fluid

- Cleanability

- Easy cleaning design

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Abrasion resistance

- High durability construction

- Density/particle size

- Adaptable for various oil densities

- Machine footprint

- Available in two frying widths, four lengths

- Fryer tank shape

- Rectangular, designed for direct heating

- Discharge method

- Continuous sediment removal at the infeed

- Control panel type

- ProLINK enabled

- Ventilation stack

- Single or double

- Frying widths available

- Two options

- Frying lengths available

- Four options

- Drive type

- Electric or hydraulic

- Heating method

- Thermal fluid or electric

- Heating switchability

- Switch from electric to thermal fluid

- Fire suppression compatibility

- CO2 or water mist

- Ventilation stack

- Single or double