Making Chocolate Coatings

Find innovative production technology for making chocolate coatings and connect directly with world-leading specialists

Chocolate in its liquid form is a versatile confection that can serve as a coating for different desserts. The liquid chocolate-making process utilizes a chocolate coating machine and goes through a number of steps before achieving a fine, high gloss, and sharp look. What makes all of this possible is the process of tempering.

Technology picks for chocolate coatings

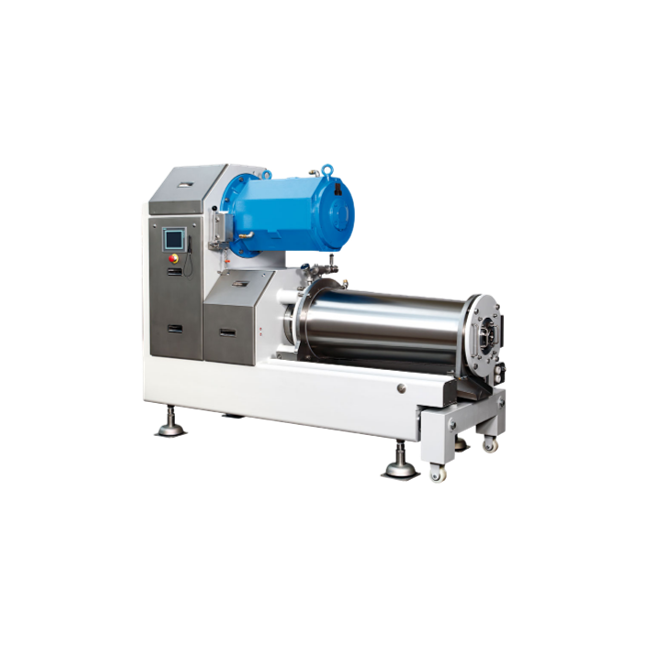

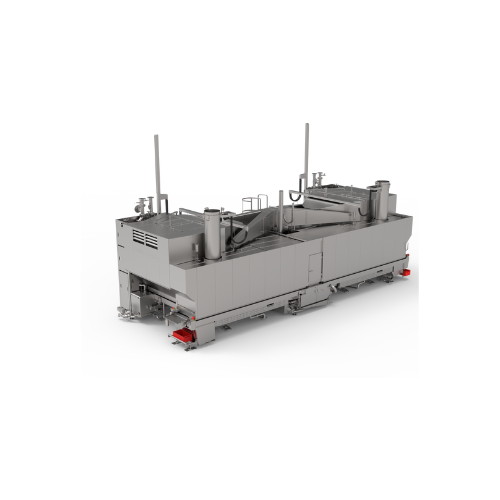

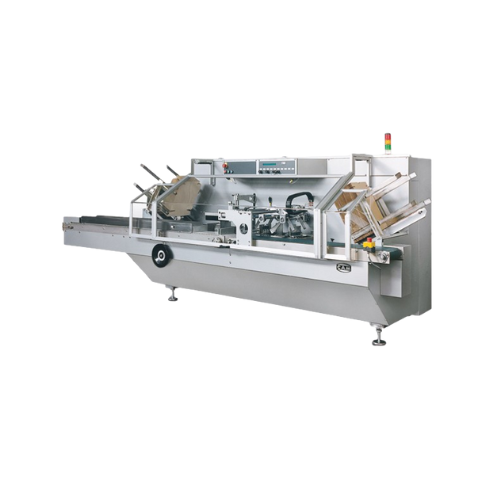

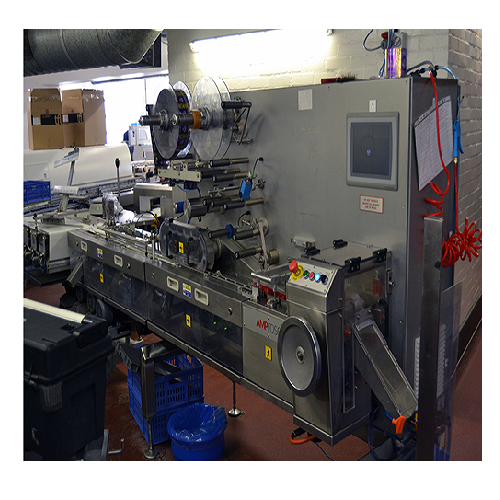

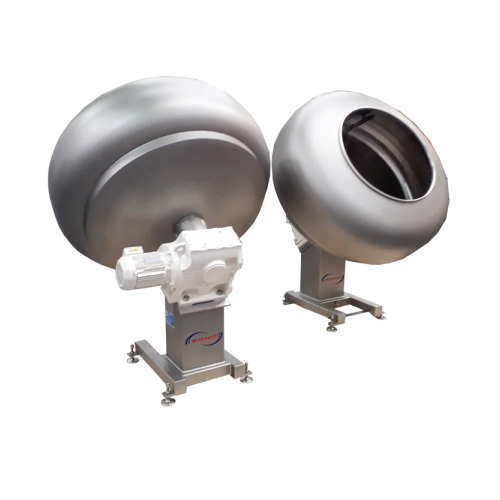

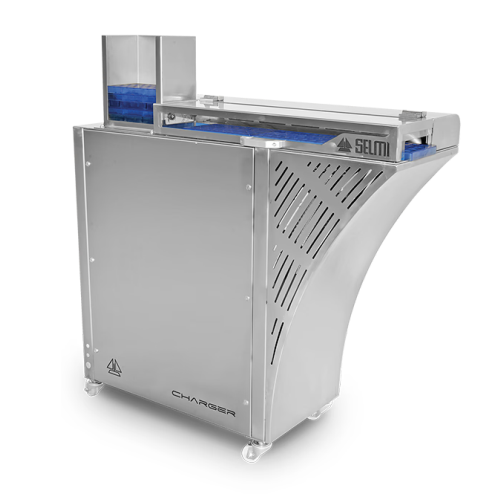

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

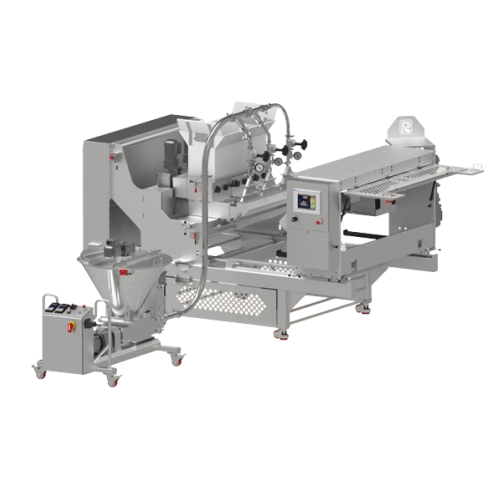

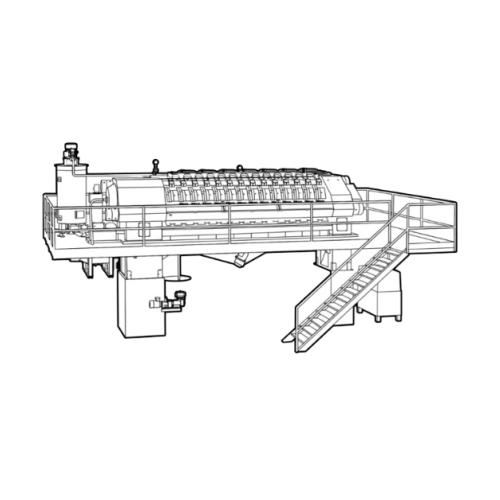

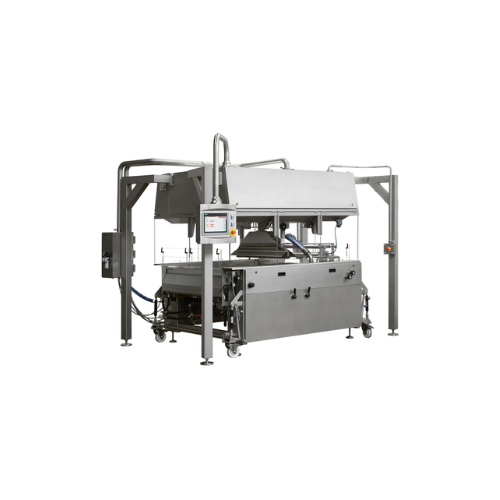

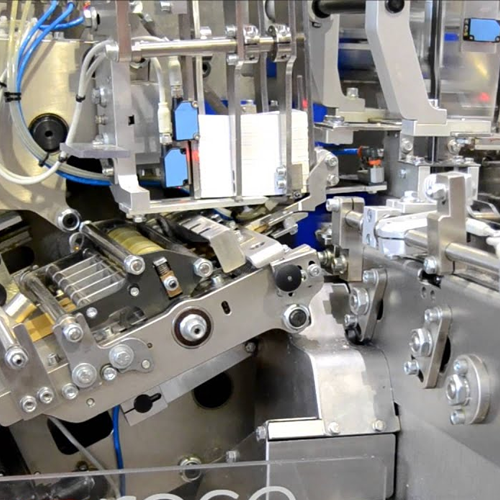

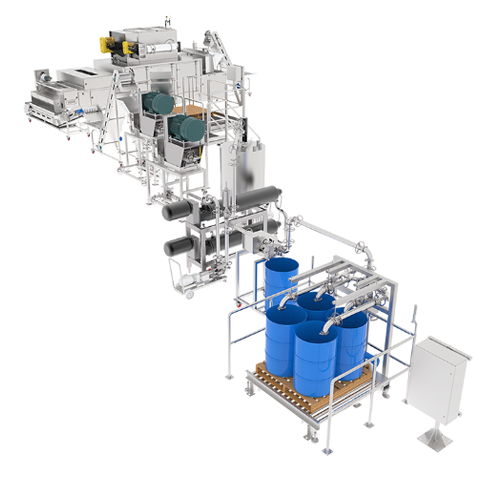

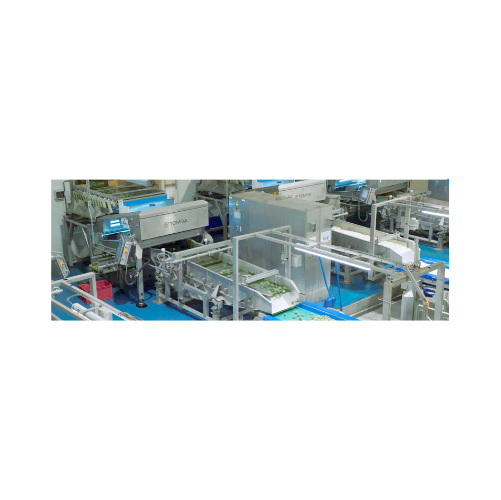

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

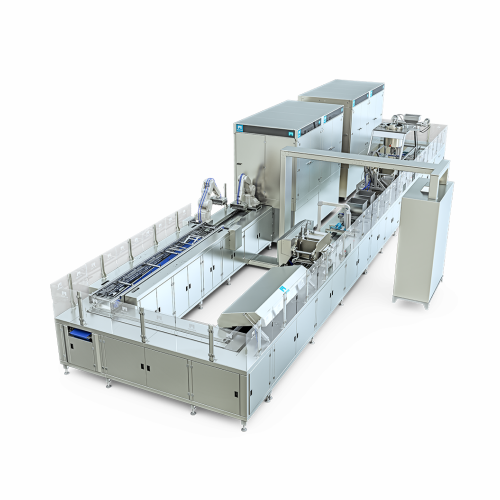

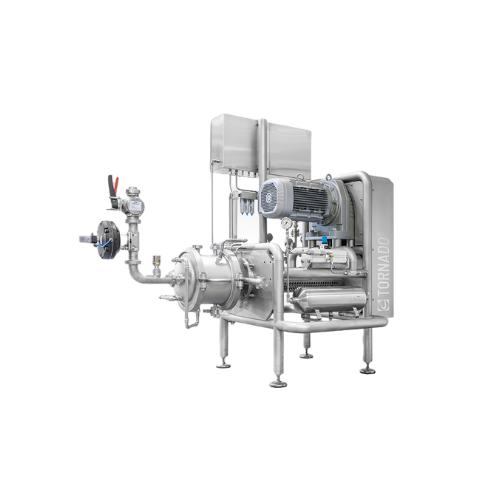

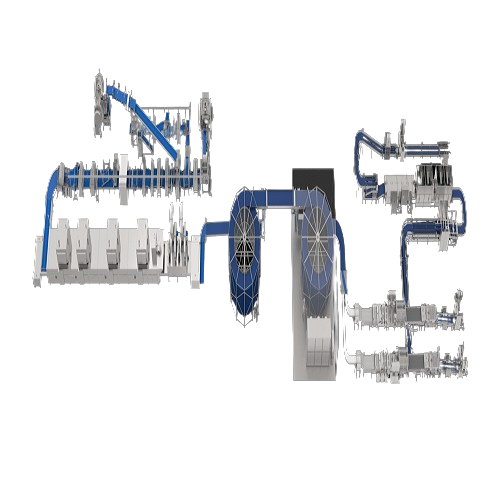

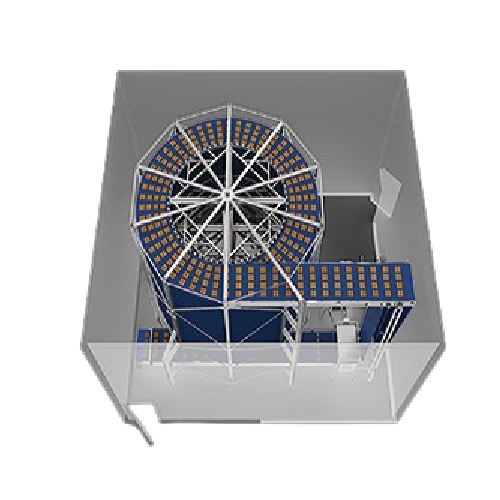

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

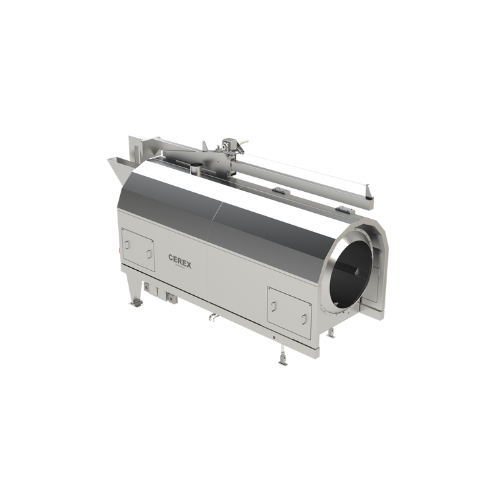

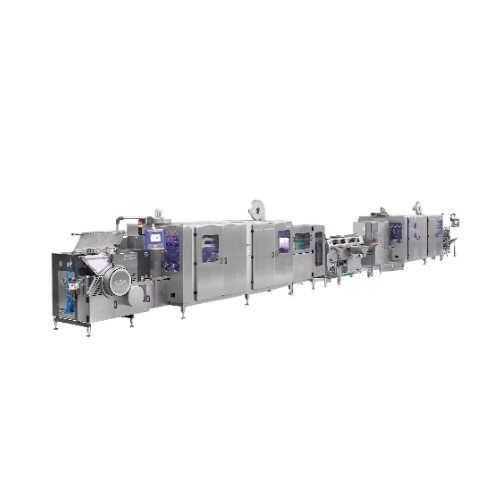

Chocolate enrobing system for industrial production

Effortlessly transition between chocolate types in your high-speed pr...

Stories about chocolate coatings

Tell us about your production challenge

Primary standards of chocolate coatings

The FDA has specific qualifications for classifying standard-of-identity chocolate, each of them with certain levels of cocoa solids and milk solids. For instance, sweet chocolate requires a minimum of 15% of chocolate liquor and up to 12% of milk solids. Meanwhile, semi-sweet and bittersweet chocolate raise the chocolate liquor to 35%. The FDA also requires that chocolates have only cocoa butter and dairy fat as fats. Otherwise, they are not considered chocolate by US standards anymore.

The European Union, however, allows up to 5% of vegetable fats in their chocolate products. In pure and semi-sweet chocolates, cocoa solids play a major role. They provide distinctive flavors that will eventually evolve once the manufacturing process takes place. In contrast, milk chocolates have dairy solids as the main source of solids in chocolate. Depending on the dairy ingredient, the flavor profiles might be different.

Importance of tempering and advantages of using chocolate coating machines

Producers employ tempering due to the unique crystallization process of cocoa butter. They melt the chocolate out, then remove any crystal formations and cool the chocolate at an optimal temperature. It cannot be too high or too low, so stable crystals, such as beta crystals, can form and remain in place. If you compare it to regular solidification, tempering provides the best appearance and texture of the chocolate that doesn’t degrade over time. To achieve this, the chocolate tempering machine heats chocolate to 50 °C (122 °F) for the melting process and cools it down to 27 °C (80.6 °F), allowing beta crystals to form.

Chocolate coating alternatives

Due to consumers’ health concerns, the industry has been using healthy oils and fats in various food products. These also include chocolates. Manufacturers are constantly researching cheap and healthy alternative compound coatings for chocolates. Instead of cocoa butter, vegetable fats can be a low-cost alternative in producing chocolate coatings using reliable chocolate coating machines in the process. They should also deliver improved texture, taste, and stability because of increased pure fat content in vegetable oils, such as coconut oil. Vegetable-fat, compound coatings are also healthier due to the reduced sugar content. They are comparable to cocoa butter in terms of quality, even without tempering.

Processing steps involved in chocolate coatings making

Which chocolate coatings technology do you need?

Cakes and pastry side injector

Enhance your bakery production with precision side injection technology that efficiently fill...

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creat...

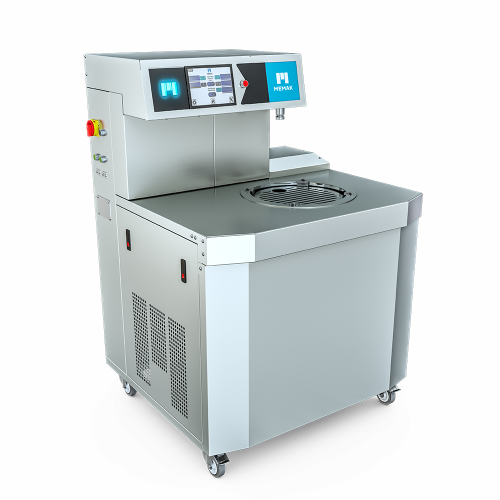

Chocolate tempering quality analyzer

Ensure your chocolate’s tempering precision with a device that accurately assess...

Heating cabinets for chocolate processing

Optimize your confectionery production by maintaining precise temperature contro...

Chocolate melting trays for small-scale applications

Efficiently melt chocolate with precision and ease using compact, el...

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

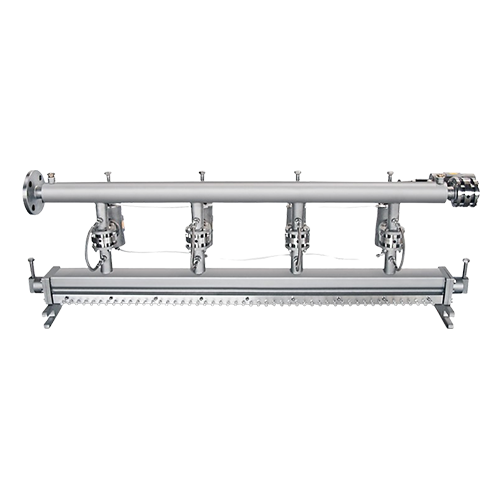

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

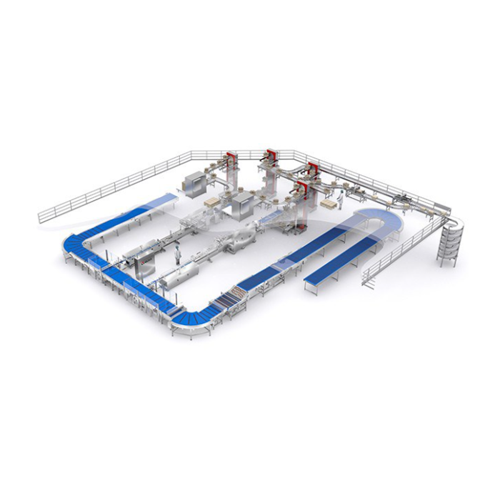

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Melting and mixing kettles for chocolate production

Achieve consistent melting and mixing of chocolates, butter, and jams...

Continuous tempering machine for chocolate production

Streamline your chocolate production with precise tempering, ensuri...

Chocolate transport system for feeding and packaging

Enhance your chocolate production with a versatile transport system ...

Nuts dosing system for chocolate drops

Effortlessly create consistently accurate chocolate-covered nut products with precis...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Cooling tunnel for biscuit and chocolate production

Ensure consistent quality control in your confectionery production wi...

Continuous cooler for biscuits and chocolates

Enhance cooling efficiency for your confectionery and bakery production with...

Chocolate melter for large quantities

Efficiently melt and maintain the temperature of substantial chocolate quantities wit...

Melting and mixing kettle for chocolate production

Optimize your confectionery production with this versatile melting and...

Compact chocolate tempering solution

Enhance your chocolate products’ finish and efficiency: this compact solution en...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Batch tempering solution for chocolate production

Achieve precise temperature control for chocolate consistency and quali...

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

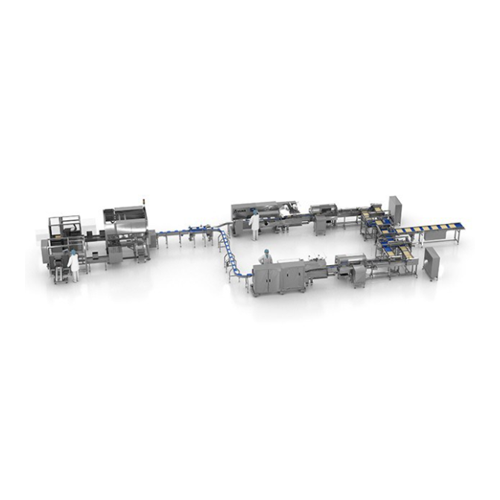

Industrial chocolate enrobing system for biscuits and fillings

Enhance your production line with this innovative enrobin...

Double heating cabinet for melting and preheating chocolate

Optimize space while ensuring precise temperature control fo...

Electric melting tray for small-scale chocolate applications

Effortlessly melt and prepare chocolate with precision and ...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Chocolate coating system for nuts and small biscuits

Effortlessly achieve consistent chocolate coatings on nuts, fruits, ...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Continuous cooking unit with vacuum for candy production

Achieve precise caramelization and cooking with enhanced flavor ...

Fat melting tank for confectionery production

Melt solid fat blocks efficiently to streamline your caramel, nougat, and ch...

Fat slurry homogenization mill for chocolate processing

Achieve precise chocolate and confectionery homogenization with e...

Invert sugar and glucose storage tank

Optimize your sweet and confectionery production by efficiently storing and resting g...

Dough divider for high-efficiency bakery production

Achieve precise dough division and high-speed production efficiency w...

Industrial storage tank for chocolate ingredients

Ensure consistent quality for your confectionery products by integratin...

Automatic one-shot moulding line for chocolate production

Streamline your chocolate production with a versatile line tha...

Chocolate drop production line

Enhance your chocolate processing capabilities with precision depositing and moulding, delive...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

Automatic chocolate feeding conveyor

Efficiently connect your chocolate production to wrapping stages with this high-speed ...

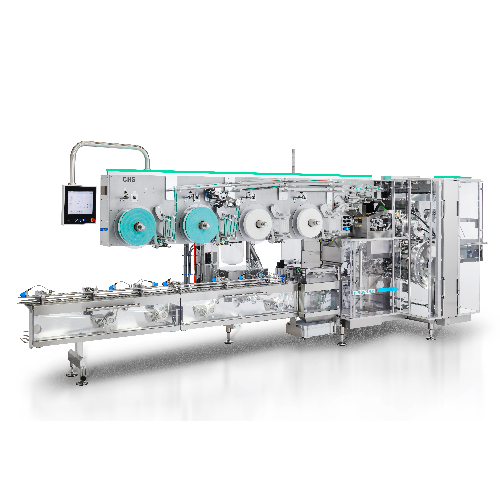

Chocolate wrapping machine for confectionery production

Achieve precision and elegance in packaging with high-speed wrapp...

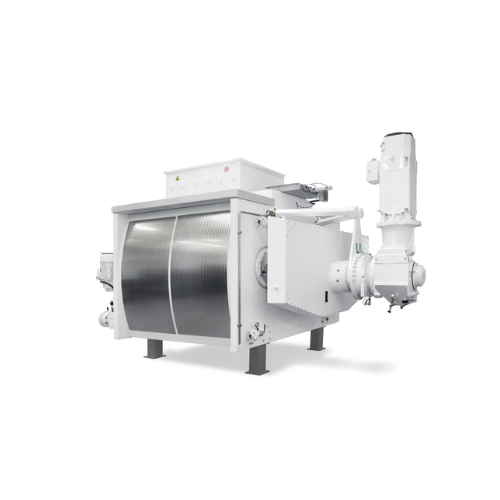

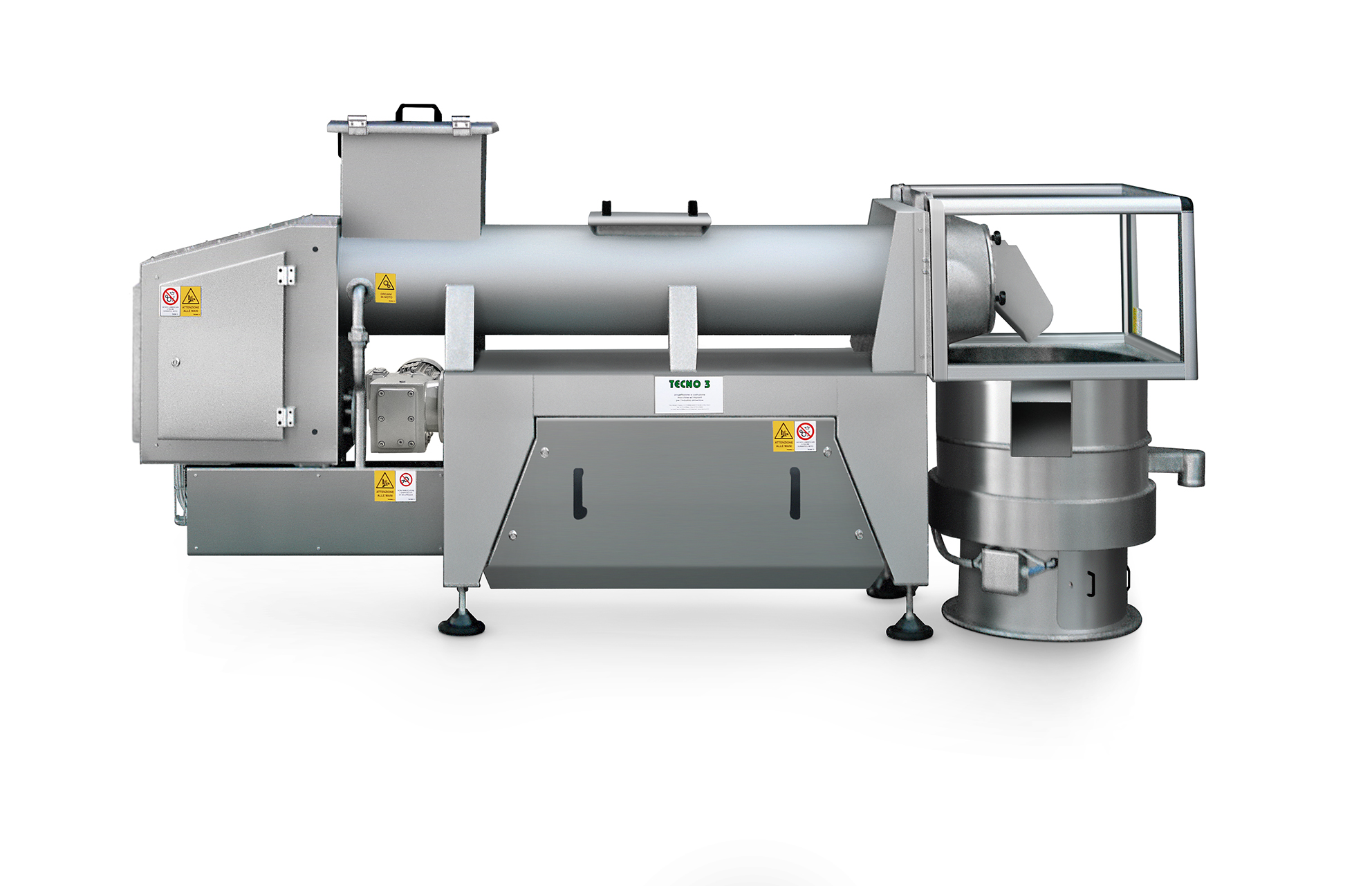

Chocolate raw material pre-mixer

Streamline your chocolate production by efficiently combining raw ingredients in a single p...

Chocolate storage tank

Optimize your chocolate production with seamless storage solutions that ensure consistent quality and ...

Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that e...

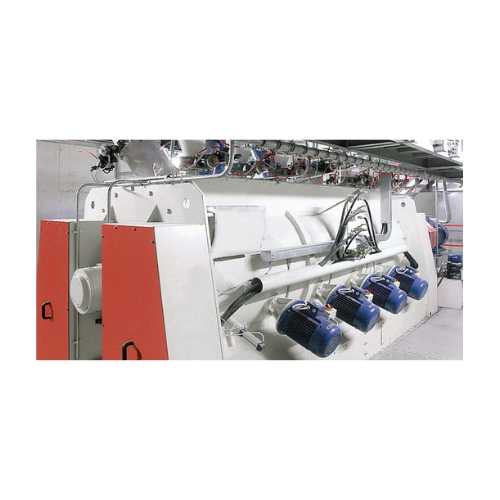

Conching solution for chocolate processing

Achieve optimal chocolate texture and flavor by ensuring efficient conching, cr...

Laboratory type ball mill for chocolate and bakery applications

Optimize your R&D processes with precise grinding a...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Chocolate cooling tunnel

Enhance your confectionery production with efficient cooling and precise crystallization, critical f...

Enrobing system for high-quality chocolate applications

Enhance your confectionery line with precise chocolate coating ca...

Chocolate ball mill for processing chocolate mass

Enhance your confectionery production with precision mixing and uniform...

Rotary rack oven for bakeries

Efficiently handle diverse baking needs with precise temperature and steam control, ensuring c...

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Spiral oven for cooking plant-based and conventional products

Achieve perfectly cooked products every time with advanced...

Inline chocolate filter for large particle removal

Ensure the purity and consistency of your chocolate products by effici...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Chocolate refiner/conche system

Streamline your chocolate production with a versatile solution that combines grinding, mixin...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

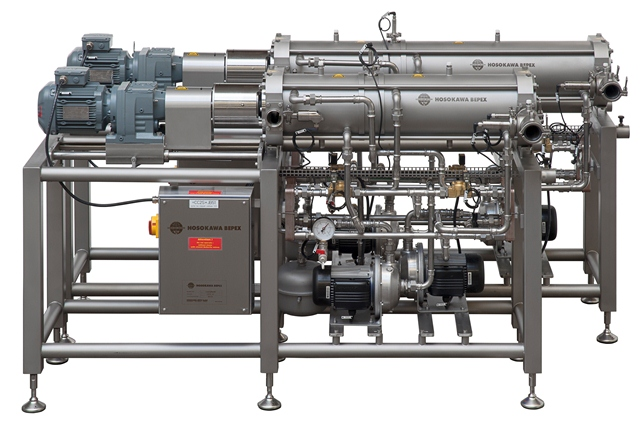

Mid-shear mixer for powders and bulk solids

Achieve ultra-short mixing cycles and superior homogeneity without the need fo...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

Wafer cutting system for cream-filled wafers

Achieve precise cuts on filled and coated wafer products with high-speed effi...

Wafer sheet conditioning tunnel for chocolate coating

Optimize your chocolate-coated wafer production by ensuring precise...

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Automatic wafer baking machine for high-capacity production

Streamline your wafer and snack production with a high-speed...

Continuous conveyor belt dryer for endless products

Optimize your continuous production line with a high-speed drying sol...

Cocoa pressing plant for high-capacity cocoa liquor processing

Optimize your cocoa processing by converting cocoa liquor...

Continuous cocoa bean roaster

Achieve precise flavor profiles in cocoa and nut processing with a continuous roasting solutio...

Chocolate refining five-roll refiner

Achieve optimal chocolate texture with high-efficiency refining, reducing energy usage...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Tablet coating system for aqueous, solvent, and sugar films

Achieve precision coating with flexible application capabili...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Chocolate, syrup, and fat melting tank

Achieve precise melting and temperature control for chocolate, syrups, and fats, ens...

Gear or piston filling-dosing equipment for creamy and thick foods

Efficiently dose and fill dense and creamy products ...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

Continuous aeration system for confectionary and bakery products

Optimize your production line with precise, high-speed ...

Industrial sugar melter

Efficiently melt and mix sugar with precision using a gas-fired batch cooker designed for optimal hea...

Single-zone toasters for raw grain processing

Optimize your cereal and snack food production by achieving consistent toast...

Industrial coating drum for breakfast cereals

Optimize your cereal production with a coating drum designed to enhance prod...

Coating dryers for breakfast cereal production

Achieve precise moisture control in coated cereal production with these mod...

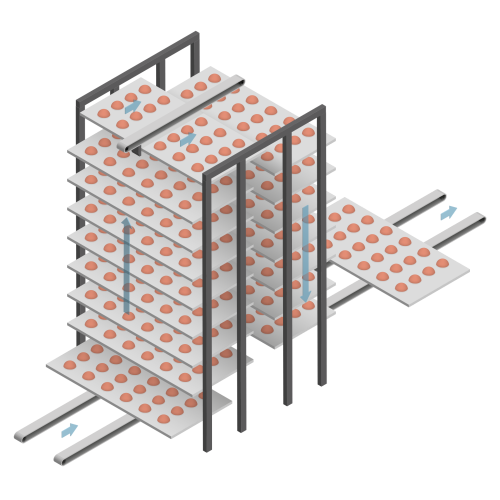

Multi-tier dryers for modern breakfast cereals

Optimize dry and cool cereal, nuts, and seed production with a compact modu...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Fully automatic chocolate processing line

Accelerate your chocolate and confectionery production with this high-speed syst...

Laboratory batch chocolate processing unit

Achieve precision in developing chocolate recipes with a compact 3-in-1 unit th...

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

Laboratory conching solution for small batches of chocolate

Optimize your chocolate formulations with precise moisture a...

Automatic chocolate processing line

Transform your production by automating the complete chocolate-making process—from prec...

Ball mill refiner for cocoa liquor and chocolate production

Optimize your cocoa and chocolate refinement with precise gr...

Tray and lid forming solution for food packaging

For manufacturers needing precision packaging, this machine seamlessly fo...

Wafer block spiral cooler

Enhance your confectionery production with a modular spiral cooler that ensures gentle handling an...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Commercial pasta press for diverse ingredients

Optimize your pasta production with a flexible solution capable of handling...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Archway-type wafer sheet cooler

Enhance your wafer production line with an efficient cooling solution that seamlessly integr...

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced en...

Single-shaft conche for chocolate production

Optimize your chocolate production with a conche that delivers shorter conchi...

Wafer acceleration belt for chocolate enrobing

Optimize your confectionery production with precise wafer separation and al...

High-speed wafer block building device

Streamline your wafer production with this high-speed device, expertly folding and p...

Continuous wafer oven

Optimize your wafer production with precise temperature control and efficient energy use, minimizing ga...

Advanced enrobing line for confectionery

For confectionery producers seeking seamless chocolate coating versatility, our en...

Five-roll refiner for chocolate production

Achieve precise particle size control and energy efficiency in your chocolate r...

High-performance bead mill for wet grinding and dispersing

Optimize your production line with a bead mill designed for e...

Full-volume bead mill for wet grinding applications

Achieve superior dispersion and particle size consistency with advanc...

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Debacterizing system for cocoa beans

Ensure your cocoa processing meets stringent hygiene standards with this advanced deba...

Cocoa nibs and malt roaster

Achieve precise roasting, sterilization, and taste control of cocoa and malt with adaptable heat...

Lab-scale twin screw extruder

Optimize your material testing and production efficiency with our versatile twin screw extrude...

Lab-scale extruders for material development

Optimize your lab and pilot-scale extrusion processes with advanced material ...

Frozen product cleaning and sizing system

Achieve precise cleaning and sizing of frozen goods effortlessly, enhancing prod...

Centrifugal separator for reworking chocolate and chopped hazelnuts

Efficiently separate chocolate from chopped hazelnu...

Chocolate spraying system for bakery decoration

Achieve precision chocolate coatings and intricate dessert decorations eff...

Automatic aligning and rack loading solution for xiao long bao production

Improve efficiency in food production by sea...

Wrapper for flat bottomed chocolate articles

Optimize your confectionery packaging with a machine designed for swift, secu...

Neapolitan chocolate wrapping solution

Efficiently wrap and label square chocolates with this fold wrap solution, ideal for...

Chocolate moulding line for filled and inclusions bars

Achieve seamless chocolate production with modular flexibility, al...

Automated sheeting and laminating solution for filled snack bread production

Enhance your bakery line’s efficien...

Spiral cooler for industrial baking

Enhance your bakery’s efficiency and product quality with modular cooling solutio...

Atmospheric powder induction system

Enhance your mixing efficiency with a system designed for rapid powder induction and th...

Conveyors for material handling in food processing

Streamline your snack production line with conveyors designed to effic...

Integrated nut butter production line

Enhance your nut processing capabilities with a fully integrated production line that...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Cooling simulator for chocolate production optimization

Optimize your chocolate cooling processes and refine production s...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Chocolate enrober for large scale production

Efficiently enrobe a wide range of products, from chocolate bars to delicate ...

Bottom enrober for chocolate and confectionery products

Optimize your production line with precise bottom enrobing, ensur...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Depositor for aerated masses and fat fillings

Enhance your confectionery production with a depositor that precisely handle...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

Small scale chocolate enrober

Ideal for creative small-scale producers, this enrober allows you to experiment with chocolate...

Energy efficient enrober for chocolate coating

Enhance your production with energy-efficient enrobing that ensures precise...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Industrial chocolate enrober

Achieve exceptional chocolate coating consistency and efficiency with this advanced enrobing te...

Conveyor system for chocolate production lines

Streamline your production flow with this conveyor system, ensuring efficie...

Auxiliary feeder mixer for chocolate production

Optimize ingredient incorporation seamlessly with a versatile system that ...

Filling and weighing station for chocolate production

Ensure precise and efficient chocolate mass depositing with a stati...

Industrial guillotine for precision cutting

Achieve precise portioning with a high-capacity guillotine, designed for seaml...

Chocolate pump for consistent mass transport

Efficiently transport chocolate mass with precision, ensuring gentle handling...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Wafer and biscuit feeder for chocolate moulding

Efficiently integrate wafers and biscuits into your chocolate production l...

Chocolate quality measuring instrument

Ensure consistent chocolate quality by accurately measuring contraction, expansion, ...

Accurate chocolate tempering measurement tool

Ensure precise chocolate tempering with real-time accuracy, enhancing qualit...

Fast crusting freezer for poultry products

Ensure optimal product integrity by rapidly sealing moisture in seconds, preven...

Coated lollipop production line

Transform your confectionery line with a solution that forms, cools, and coats 3D lollipops ...

Cooling system for post-baking stabilization

Optimize your production line by integrating a cooling system that ensures po...

Laboratory mixer for complex mixing tasks

Optimize your laboratory processes with a versatile mixer designed for accurate ...

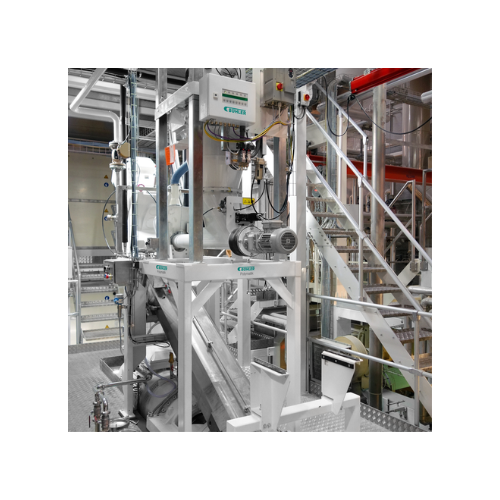

Advanced plant engineering services

Optimize your production line with seamless integration of high-efficiency mixing, dosi...

Industrial coating pans for sweets and confectionery

Ensure even and consistent coatings with high-capacity pans designed...

Coating pans for precision culinary coatings

Achieve consistent, high-quality coatings on a diverse range of products, fro...

Dissolver for high-viscosity products through floor installation

Optimize production of ultra-high viscosity products wi...

Dispersing system for high-viscous products

Achieve precise mixing and dispersing of high-viscous products with advanced f...

Triple shaft mixer for high-viscosity products

Achieve precision mixing and dispersing of high-viscosity products with a p...

Batch-type single shaft mixers with bomb-bay discharge

When you need rapid, residue-free discharge in your batch mixing p...

Basket mill with integrated dissolver for high viscosity products

Optimize your production efficiency by combining disp...

Tank agitator for low-level installation

Efficiently optimize your mixing processes with a bottom-entry tank agitator, desi...

Laboratory stirrer for small batch mixing

Achieve consistent mixing and blending in small-scale environments with minimal ...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Automatic rotary premade pouch filler for various industries

Streamline your pouch packaging process with precision fill...

Biscuit packaging and boxing solution

Streamline your biscuit production line with a fully automated system that ensures pr...

Automated packaging line for wafers

Optimize your wafer production with high-speed, fully automated packaging and versatile...

Advanced fruit sorting platform

Optimize your operations with a cutting-edge sorting solution designed to enhance product in...

Advanced food sorter for tomatoes and peaches

Achieve precise sorting and defect removal for a variety of food products, e...

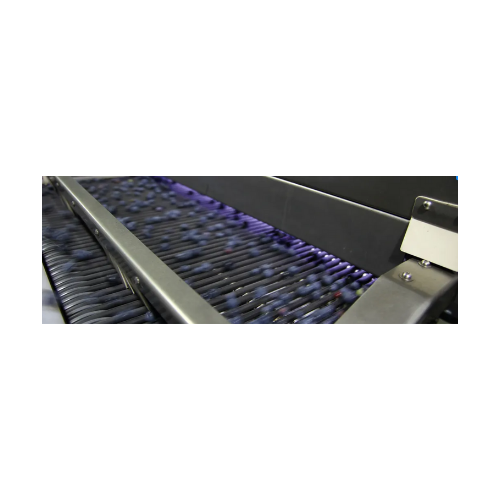

Blizzard sorter for Iqf fruits and vegetables

Optimize your frozen food production with a compact sorter that seamlessly r...

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality c...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

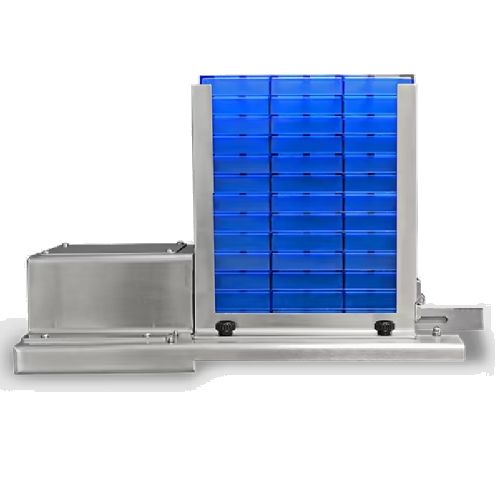

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an effi...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

Modular high-speed wrapper for chocolate flow packs

Efficiently wrap a wide range of products, from chocolate bars to dis...

High-speed wrapping system for chocolate bars

Ensure quick and precise packaging for chocolate bars with a high-speed syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

High-speed wrapping solution for preformed candies

Ensure consistent wrapping of diverse confectionery products with a hi...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

Cooking extruders for continuous food processing

Optimize your extrusion processes with cooking extruders designed for con...

Centrifugal pump station for chocolate coating applications

Ensure precise temperature control and efficient chocolate c...

Ice cream dipping and transfer unit

Streamline your ice cream production with a multi-lane system designed for precise dipp...

Chocolate enrober for ice cream products

Optimize your ice cream and dessert production with precise, high-speed enrobing a...

Static mixer for homogeneous blending of ingredients in bakery and confectionary

Achieve consistent flavor and color i...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

Cocoa bean processing line from cocoa pod to cocoa nibs

Streamline your cocoa production process by transforming raw coco...

Electrostatic drum flavouring system for food industry

Enhance the consistency of your food products with precise flavour...

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Z-conveyor for confectionery production

Ensure the gentle transport of delicate dry and granulated ingredients with a versa...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Nut clusters moulding solution

Streamline your production line with efficient nut cluster moulding, ensuring precise shape a...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Caramel enrobing system for biscuits and wafers

Achieve consistent caramel coverage with precise temperature control, ensu...

Industrial enrobing solution for quality coatings

Achieve high-quality coatings for pralines, bars, and pastries with a c...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Bottom coating system for confectionery production

Optimize your confectionery line with precision bottom coating, ensuri...

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Simultaneous chocolate dosing solution

Achieve high-precision chocolate and ganache filling in a single step with this effi...

Cocoa bean winnower

Transform roasted cocoa beans into nibs efficiently, ensuring precise separation of cocoa from its shell,...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Chocolate and spreadable cream dispenser

Effortlessly enhance your confection creations with a dispenser that precisely mel...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Chocolate coating panning machine for confectionery

Enhance your confectionery product line with a precision coating solu...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Industrial chocolate conching solution

Optimize chocolate production by effectively removing acidity and moisture, ensuring...

Flowpack packaging machine for chocolate products

Effortlessly wrap and preserve large quantities of chocolate and sweet ...

Professional chocolate tempering equipment for efficient production

Enhance your production capabilities with a versati...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Chocolate enrobing system for tempering machines

Achieve consistent, high-quality chocolate coatings for your truffles, pr...

Autonomous vibrating station for chocolate moulds

Efficiently level and smooth chocolate in moulds, maintaining a seamles...

Wall chocolate fountain for continuous chocolate flow

Create a mesmerizing ambiance with a seamless chocolate waterfall, ...

Chocolate products aligner for chocoform extruder

Enhance your chocolate production line efficiency with a precision alig...

Chocolate painting and spraying cabin with suction

Achieve impeccable decoration and coating of confectionery with a pain...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Automatic heated mould loader for chocolate production

Streamline your chocolate production with this heated mould loader...

Chocolate enrobing belt for tempering machines

Enhance your chocolate production line with precise control over coating an...

Chocolate enrobing and cooling tunnel 300/400 mm

Ensure seamless enrobing and precise cooling for chocolate products with ...

Chocolate truffle enrobing system

Enhance your chocolate production with a machine that delivers precision enrobing for tru...

Chocolate sprayer for panning machines

Enhance your confectionery creations with precision chocolate coating, ensuring ever...

Chocolate drops production system

Create perfectly uniform chocolate drops with precision dispensing and seamless integrati...

Horizontal cartoning system for coffee pods

Enhance your packaging line efficiency with a system designed for gentle handl...

Filling and sealing solution for beverage capsules

Optimize your production with a modular capsule filling and sealing so...

Mixer for production of chocolate with inclusions

Using the same mixing equipment for different recipes in chocolate manu...

Refining plant for chocolate

Achieving a balanced, velvety mouthfeel in chocolate is challenging. Larger particles in chocol...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

High-speed chocolate block melt machine

If you produce chocolate using larger blocks instead of cocoa beans, chocolate melt...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

High capacity tempering machine

Prepare chocolate mixes for application to your product as coatings. Enhance the attractiven...

High capacity compound conditioner

Enhance the appearance of coatings applied to your product by control the crystal compos...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

Small capacity chocolate melangeur

In order to produce the finest of chocolate products, you need the cocoa nibs to be grin...

Chocolate conche for small batches and laboratory use

Conching plays a critical role in the flavor development of chocola...

Automatic batch tempering machine

Automatic tempering machine, for batch process in a medium scale production.