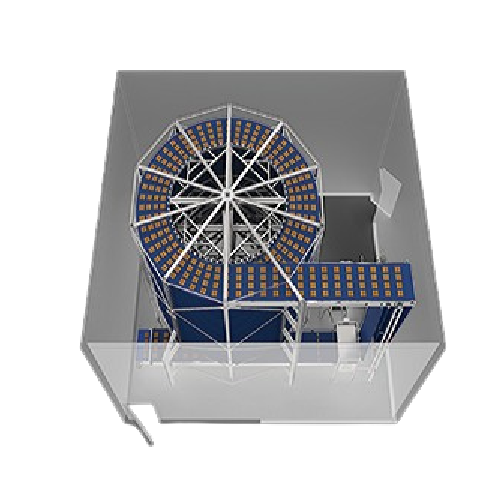

Spiral cooler for industrial baking

Enhance your bakery’s efficiency and product quality with modular cooling solutions designed for continuous operation, ensuring optimal temperature management for a variety of baked goods.

Rapidly Cools Baked Goods for Quality Assurance

The Vesta Spiral Cooler by AMF Vesta is designed to optimize the cooling phase in industrial baking production. This modular system rapidly cools various baked goods such as sourdough loaves and almond croissants, using a continuous spiral design to ensure efficient heat dissipation and moisture control. Engineered for seamless integration into high-speed production lines, it supports automated operations and control via a PLC interface, allowing remote monitoring for optimal performance. With the capacity to handle diverse product sizes and types, it suits applications from bread production to confectionery. The cooler’s hygienic design enhances sanitation, featuring easy-to-clean surfaces and accessibility for maintenance. It is constructed with durable materials that are corrosion-resistant, ensuring longevity and consistent operation in demanding industrial environments. The Vesta Spiral Cooler’s flexibility and efficiency make it a vital component in modern bakery system integration.

Benefits

- Enhances product quality by ensuring consistent cooling, preserving texture and moisture.

- Minimizes operational costs with energy-efficient continuous flow design.

- Reduces labor requirements with automated PLC-controlled systems.

- Maintains sanitary standards with easy-to-clean modular components.

- Increases production efficiency through seamless integration into high-speed lines.

- Applications

- Buns, Flatbreads, Pizza, Pies, Soft bread, Rolls, Cakes, Pastries, Croissants, Artisan bread

- End products

- Layered cakes, Chocolate-filled pastries, Almond croissants, Thin crust pizza, Savory meat pies, Whole wheat flatbreads, Sliced white bread, Sourdough loaves, Ciabatta rolls, Brioche buns

- Steps before

- Dough Depositing, Dough Dividing, Sheeting, Topping

- Steps after

- Cooling, Freezing, Packaging, Basket Stacking, Palletizing

- Input ingredients

- soft bread dough, bun dough, artisan bread dough, rolls dough, pizza dough, flatbread dough, cake batter, muffin batter, pie filling, croissant dough, pastry dough

- Output ingredients

- soft bread, buns, artisan bread, rolls, pizza, flatbreads, cakes, muffins, pies, savory pies, croissants, pastries

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Automation

- PLC-controlled

- Sanitary Design

- Easy to clean

- Oven Type

- Tunnel/Tray Ovens

- Modularity

- Custom-configured

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Modular design

- Yes

- Sanitary construction

- Yes

- Compact footprint

- Adaptable

- Cooling method

- Spiral Cooling

- Footprint adaptability

- Custom-configured

- Continuous flow system

- Yes

- Control panel type

- PLC / HMI / Touchscreen

- Integration possibilities

- SCADA / ERP / IoT

- Modularity

- Modular design for customization

- Footprint scalability

- Adjustable layout

- Custom-configured design

- Tailored to bakery needs

- Product type compatibility

- Bread, Buns, Pizza, Pies

- Sanitation level

- Simple sanitation design