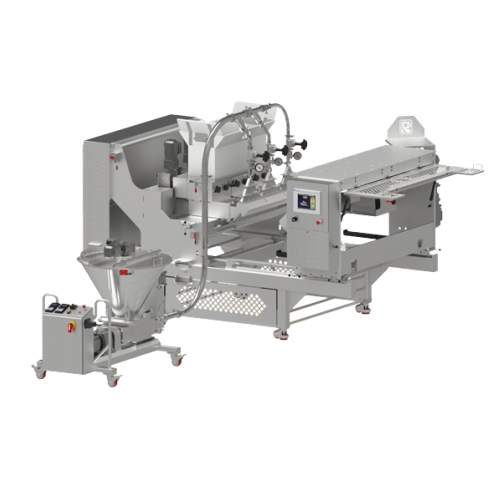

Filled stick extruder for bakery products

Streamline your snack production line with a versatile extruder capable of creating filled stick products like cheese-filled breadsticks and chocolate pastries, enhancing product variety while ensuring precise filling and consistent quality.

Extrudes and Fills Diverse Snack and Bakery Products

The Filled Stick Extruder from Reading Bakery Systems is engineered to streamline the production of diverse snack and bakery items. It excels in creating filled snack sticks by utilizing low-pressure extrusion and precision co-extrusion of both dough and a soft filling. This system accommodates applications such as snack and bakery production and co-extruded pet treats. It features customizable die and compression heads for seamless product changeovers.

With an output capacity tailored to suit your line requirements, its modular design allows integration with existing systems, enhancing production line efficiency. The extruder’s control systems are fully PLC-automated, offering real-time monitoring and precise flow control, while optional temperature management supports sensitive dough consistency.

Constructed with easy-to-clean materials and designed for tool-free disassembly, the system supports stringent sanitation standards. Available configurations include 1 to 6 extrusion units, making it adaptable to various production scales. Additionally, Reading Bakery Systems provides ongoing engineering support and customization options to fit specific production needs.

Benefits

- Enhances production flexibility with quick and easy product changeovers.

- Improves filling accuracy and consistency for high-quality, co-extruded products.

- Minimizes labor requirements through an intuitive PLC-controlled interface.

- Ensures food safety and sanitation with easy-to-clean components and tool-free disassembly.

- Integrates seamlessly into existing lines, optimizing overall production efficiency.

- Applications

- Cookies, Biscuits, Snacks, Pet food, Popped snacks, Expanded snacks, Sweets, Crackers, Granola, Bakery products

- End products

- Air-popped snack clusters, Granola bars, Co-extruded pet treats, Cheese-filled breadsticks, Stuffed biscuits, Chocolate-filled pastries, Cream-filled cookies, Peanut butter-filled snack sticks, Flavored crackers, Filled pretzel sticks

- Steps before

- Mixing, Dough Handling, Batch Mixing

- Steps after

- Guillotine Cutting, Baking, Drying

- Input ingredients

- dough, soft fillings, cheese, peanut butter, chocolate

- Output ingredients

- filled sticks, co-extruded products, dough sticks, product rope, nuggets

- Market info

- Reading Bakery Systems is renowned for its expertise in designing and manufacturing innovative industrial bakery equipment, particularly for snack food production, combining advanced technology and industry knowledge to enhance productivity and quality.

- Extrusion Units

- 1 to 6 per unit

- Unit Width

- 13" (330 mm) or 15" (380 mm) per unit

- Changeover Time

- Quick die and compression head changes

- Control Interface

- Touchscreen

- Dough Flow Control

- Individual pump control

- Automation Level

- PLC-controlled

- Temperature Control System

- Optional, for sensitive dough

- Working mechanism

- Extrusion system with pump for filling

- Integrated steps

- Extrusion, filling, and cutting

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- PLC-controlled

- Changeover time

- Quick die and head changeovers

- Cleaning method

- Tool-free disassembly and mobile cleaning

- Temperature control

- Optional temp control system in extrusion housing

- Safety features

- Automatic controls and interlocked guards

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity of filling

- Low to medium

- Machine footprint

- Varies by configuration

- Extrusion units

- 1 to 6 units

- Extrusion unit size

- 13" (330 mm) or 15" (380 mm) per unit

- Discharge method

- Guillotine Cutter

- Die and compression head

- Customizable

- Temperature control system

- Optional

- Control panel type

- Touchscreen control interface

- Integration possibilities

- Mated to existing Extruder

- Die and compression head customization

- Custom die and compression heads

- Extrusion units

- 1 to 6 extrusion units

- Extrusion size per unit

- 13" (330 mm) or 15" (380 mm)

- Temperature control option

- Optional temperature control system