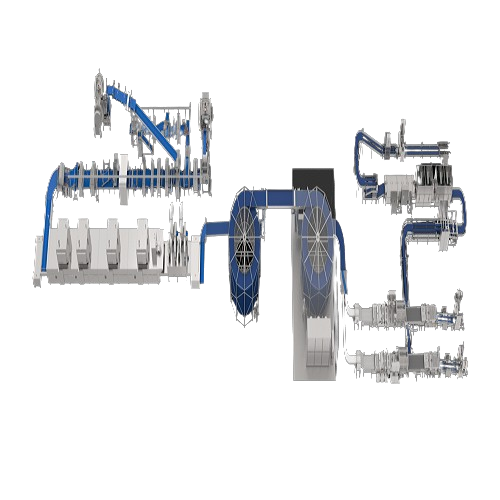

Automated sheeting and laminating solution for filled snack bread production

Enhance your bakery line’s efficiency and reduce handling stress with a system designed to streamline the production of filled snack breads, from dough mixing to packaging, ensuring consistent quality and uniformity.

Produces Filled Snack Bread Products

AMF Bakery Systems presents the Filled Handheld Snack Production System, an engineered solution designed for efficient production of filled snack bread products. This system excels with its integrated process that combines mixing, sheeting, laminating, and more, ensuring seamless operation from start to finish. Perfect for creating filled bread snacks, stuffed croissants, and cream-filled pastries, this scalable system is ideal for high-volume industrial bakeries and food production companies. Designed for continuous operation, it handles high-speed production with minimal downtime, optimizing throughput and maintaining consistent product quality. Automation is driven by AMFConnect™, offering real-time data for improved decision-making. The durable construction includes options for stainless steel components, enhancing longevity and resistance to food processing conditions. Compliance with industry standards ensures safe, hygienic operations, while customization options allow for tailored solutions to meet specific production requirements.

Benefits

- Enhances production capacity with seamless integration into existing lines.

- Maintains product consistency, ensuring high-quality filled snack products.

- Boosts operational efficiency through continuous, automated processes.

- Reduces labor requirements with real-time monitoring and data access.

- Minimizes maintenance with durable, corrosion-resistant materials.

- Applications

- Buns, Snacks, Puff pastry, Croissants, Rolls, Pastries, Bread products, Bakery products, Filled snacks, Danish

- End products

- Spinach and cheese snacks, Sweet-filled pastries, Cream-filled puff pastries, Chocolate-filled pastries, Stuffed croissants, Flavored rolls, Soft buns, Fruit-filled danish, Dinner rolls, Filled bread snacks

- Steps before

- Mixing, Dough Distribution, Dough Chunking, Elevating, Sheeting, Laminating

- Steps after

- Proofing, Baking, Cooling, Freezing, Conveying, Packaging, Product Loading, Basket Stacking, Washing, Drying

- Input ingredients

- dough, filled snack ingredients, raw dough

- Output ingredients

- filled snack bread, croissants, pastries, danish, puff pastry, moulded bread products

- Market info

- AMF Bakery Systems is known for providing automated bakery equipment solutions, specializing in complete system design and integration for high-speed bread and bun production lines, emphasizing innovation, precision, and reliability in the baking industry.

- Mixing Capacity

- up to 3, 200 lbs

- Dough Distribution Capacity

- up to 30, 000 lbs/hour

- Baking Control

- Independent zone control

- Conveyor Type

- A-Series with anodized aluminum

- Freezer Configuration

- Custom-configured modular design

- Laminating Speed

- High-speed

- Product Diverter Speed

- up to 35 actions per minute

- Basket Unstacking Speed

- up to 40 baskets per minute

- Basket Denester Speed

- up to 34 baskets per minute

- Automation level

- Integrated / Scalable

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Quick / Easy

- Cleaning method

- CIP / Manual

- Energy efficiency

- Optimized for reduced consumption

- System integration

- Seamless with AMFConnect™

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Gentle handling systems

- Custom-configured elements

- Sanitary, modular design

- Control panel type

- AMFConnect™ HMI

- Integration possibilities

- Real-time data access, Seamless integration

- Conveyor type

- Custom-configured, modular design

- Cooling system

- Vesta Spiral Cooler

- Freezing system

- Vesta Spiral Freezer

- Baking system

- Den Boer Multibake Tunnel Oven

- Laminating line

- Tromp Laminating Line

- Sheeting line

- Tromp Stress-Free Sheeting Line

- Mixing capability

- Sanitary Open Frame Mixer