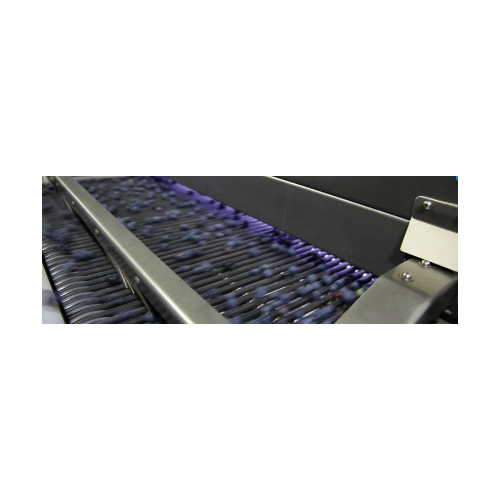

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality control by identifying and separating defective produce, ensuring that only the finest batches reach your packaging stations.

Sorts and Inspects Food Products Efficiently

The Color Sorter from TOMRA offers an efficient solution for high-speed sorting and inspection across a wide spectrum of food applications. Specializing in fruits, nuts, seeds, vegetables, and more, this equipment is designed to tackle the demanding challenges of food processing environments. Utilizing advanced optical and high-speed color sorting technology, it identifies and separates defective or off-specification products with an accuracy rating of up to 95%.

Capable of processing up to 120 kg per minute, the system ensures minimal fruit contact while maintaining high throughput rates. Its integration with the FreshTracker management system offers intelligent traceability and precise adjustments to accommodate different product sizes. Constructed from stainless steel, the Color Sorter is designed for easy cleaning and compliance with food safety standards. Ideal for fruit packhouses and food processing companies, this machine aligns with your operational goals, minimizing waste and boosting productivity.

Benefits

- Maximizes throughput with 95% sorting accuracy, minimizing product loss.

- Enhances operational efficiency with real-time traceability and easy size adjustments.

- Reduces waste and ensures quality with precise defect detection technology.

- Minimizes cleaning downtime with stainless steel, easy-to-clean construction.

- Lowers operational costs by optimizing resource usage and preventing recalls.

- Applications

- Protein, Potatoes, Confectionery, Fruits, Coffee beans, Vegetables, Nuts and dried fruit, Seeds and grains

- End products

- Cherries for confectionery, Lentil packs, Walnut baking supplies, Potato chips, Blueberry packs, Canned peas, Almond snack packs, Frozen potato fries, Bean packets, Olive oil bottling, Pet food, Raisin boxes, Cashew trail mix, Meat processing, Chocolate-covered nuts, Cranberry candy, Coffee bean sorting, Dehydrated vegetable mixes, Dehydrated potato flakes

- Steps before

- Harvesting, Sorting and selecting, Washing, De-stemming

- Steps after

- Packing, Labeling, Cold storage, Transport

- Input ingredients

- blueberries, cranberries, cherries, olives, small fruits

- Output ingredients

- sorted blueberries, sorted cranberries, sorted cherries, sorted olives, sorted small fruits

- Market info

- TOMRA is known for its expertise in sensor-based solutions for resource productivity, particularly in recycling, food sorting, and mining industries, offering advanced technology to improve resource recovery and efficiency, enhancing sustainability and operational performance.

- Speed

- Up to 120 kg (265 lb) per minute

- Accuracy

- Up to 95% sorting accuracy

- Material

- Stainless steel

- Defect Detection

- Color differences, over-ripe, diseased, bird-pecked, decayed

- Working mechanism

- Color sorting via sensors and software

- Integrated steps

- Defect detection, sorting, and traceability

- Batch vs continuous operation

- Continuous operation at high speed

- Changeover time

- Quick adjustments between sizes

- Automation level

- Automated with FreshTracker integration

- Cleaning method

- Easy cleaning due to stainless steel construction

- Energy efficiency

- Optimized for minimal waste

- Abrasion resistance

- High

- Biological compatibility

- Safe for food handling

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Discharge method

- High-speed output

- Material

- Stainless Steel

- Feed capacity

- Up to 120 kg/min

- Cleaning ease

- Easy to clean

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- Supports FreshTracker management system

- Material

- Stainless steel

- Cleaning ease

- Easy to clean design