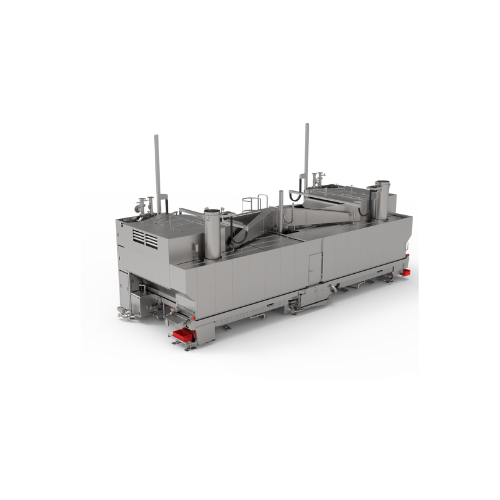

Spiral oven for cooking plant-based and conventional products

Achieve perfectly cooked products every time with advanced spiral oven technology, ensuring even heat distribution and precise temperature control for a variety of food items, from veggie burgers to seafood patties.

Steams, Cooks, and Grills Diverse Food Products

The SpiralOven from Marel offers tailored solutions for food processors looking to enhance product quality across a range of applications, including plant-based and convenience foods. This oven employs dual-zone design for independent control of cooking parameters, ensuring even heat distribution and optimal yield for diverse products like veggie burgers and grilled vegetables. Operating at medium to high capacity, the SpiralOven supports continuous, high-speed production with automated functionality.

The sophisticated air regulation provides consistent cooking, while Innova software enhances production monitoring and data collection, ensuring products meet stringent food safety standards. The system supports remote assistance to minimize downtime and optimize overall equipment effectiveness (OEE). Available in materials suited for robust food processing environments, the SpiralOven’s design facilitates easy cleaning and maintenance, supported by a global network of service professionals.

Benefits

- Ensures consistent product quality with precise control of cooking parameters.

- Minimizes unexpected downtime through unrivaled remote support capabilities.

- Increases operational efficiency with medium to high capacity continuous processing.

- Enhances food safety compliance with real-time production monitoring and data collection.

- Reduces energy consumption through optimized heat transfer and air regulation.

- Applications

- Meat products, Fish products, Snacks, Pet food, Convenience products, Cheese, Poultry products, Plant-based products, Sweets, Fruit and vegetables, Sausages, Potato specialties, Other seafood

- End products

- Veggie burgers, Chocolate-covered nuts, Plant-based nuggets, Seafood patties, Cheese sticks, Meatloaf, Dog treats, Ready-to-eat meals, Grilled vegetables, Breaded chicken fillets, Ready-to-serve snacks

- Steps before

- Preparation, Seasoning, Product Batching

- Steps after

- Packing, Labeling, Product Cooling, Storage

- Input ingredients

- veggie burgers, nuggets, plant-based products

- Output ingredients

- cooked products, grilled products, steamed products, high-quality results, consistent core temperature, even cooking, optimal yield

- Market info

- Marel is known for its advanced food processing equipment, specializing in systems and services for poultry, meat, and fish industries. It is recognized for innovation, quality, and improving processing efficiency and sustainability.

- Cooking Parameters

- Automatically regulated

- Capacity

- Medium to high capacities

- Air Regulation System

- Horizontal air regulation

- Automation

- PLC-controlled

- Remote Support

- Available

- Working mechanism

- Steaming, cooking, grilling

- Integrated steps

- Dual zone design for independent control

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Fast

- Automation level

- PLC-controlled

- CIP/SIP

- CIP capable

- Energy efficiency

- Optimized for cost-effectiveness

- Cleaning method

- CIP

- Remote assistance

- Available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Mid-sized

- Control panel type

- Advanced

- Machine footprint

- Suitable for medium to high capacities

- Zone Design

- Dual zone

- Control panel type

- HMI Touchscreen

- Integration possibilities

- Compatible with Innova Software

- Customization on cooking parameters

- Independent settings for dual zone design

- Remote support capability

- Unrivalled remote assistance available