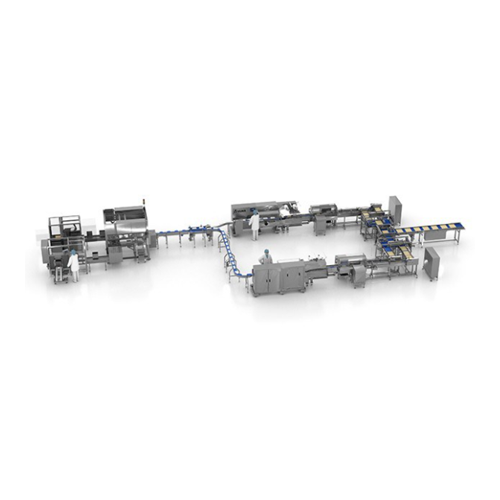

Automated packaging line for wafers

Optimize your wafer production with high-speed, fully automated packaging and versatile case packing designed to handle various wafer configurations seamlessly in one compact line solution.

Packs, Transfers, and Loads Wafers Efficiently

The Wafer Packaging and Case Packing System from ULMA Packaging is a fully automated solution designed to enhance efficiency in bakery and confectionery production lines. Utilizing a servo-controlled pusher and integrated Atlanta HT horizontal wrappers, it ensures precise transitioning and loading of processed wafer blocks. Ideal for packaging wafer cookies, cream-filled biscuits, and chocolate-coated products, it supports high-speed continuous operation. This compact system incorporates a dual-function packing cell with delta robots for top-load and side-load operations, streamlining product grouping and case packing. Designed for food manufacturers and packaging firms, it effortlessly integrates into existing lines and offers seamless processing for solid products.

Benefits

- Enhances productivity by streamlining wafer and biscuit packaging into a single, continuous operation.

- Minimizes downtime with dual packing cells for uninterrupted processing during equipment maintenance.

- Increases packaging flexibility with both top-load and side-load options in one compact system.

- Reduces manual intervention, optimizing labor efficiency through fully automated processes.

- Integrates seamlessly into existing production lines, facilitating smooth transitions and flow management.

- Applications

- Wafers, Biscuits, Snacks, Bakery, Confectionery

- End products

- Glazed donuts, Chocolate truffles, Cream-filled wafer biscuits, Toffee squares, Snack bars, Sandwich cookies, Biscuit crackers, Vanilla wafers, Wafer cookies, Chocolate-coated wafers

- Steps before

- Processing wafers, Block formation, Product distribution

- Steps after

- Cardboard boxing, 2-in-1 packing, Transfer to conveyor

- Input ingredients

- processed blocks of wafers, wafers

- Output ingredients

- primary packaged wafers, cardboard packed wafers, top load packed wafers, side load packed wafers

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated

- Packing types

- Top Load, Side Load

- Capacity

- Dual-machine feeding

- Robot type

- Delta robot

- Conveyor System

- Servo-controlled pusher system

- Pack size flexibility

- Adaptable based on machine availability

- Wrapper type

- Horizontal wrapper (Atlanta HT)

- Integration capability

- 2-in-1 packing cell

- Material handling

- Automatic diversion of products

- System Configuration

- Compact and flexible single-block

- Working mechanism

- Servo-controlled pusher system

- Integrated steps

- Primary packaging and 2-in-1 packing

- Batch vs. continuous operation

- Continuous

- Automation level

- Fully automated

- Flexibility

- Top load and side load packing

- Changeover time

- Automatic divert system for machine shutdowns

- Compact design

- Single-block packing cell

- Container size and shape

- Cardboard box

- Machine footprint

- Compact single-block

- Discharge method

- Top loading and side loading

- Control panel type

- Servo-controlled

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- PLC / SCADA integration

- Packing method

- Top Load / Side Load

- Packing cell flexibility

- Single-block, compact