Chocolate coating panning machine for confectionery

Enhance your confectionery product line with a precision coating solution designed to efficiently layer chocolate or sugar onto a variety of sweets, ensuring consistent quality and polished finishes in every batch.

Coats and Polishes Confectionery Products

The Comfit from Selmi Group is a versatile chocolate and sugar coating panning machine crafted entirely from AISI 304 stainless steel, offering high durability and resistance to corrosion. It features electronic speed control, facilitating precise coating for various confectionery products such as chocolate-covered almonds and sugar-coated candies. Its innovative system introduces controlled air into the rotating drum to accelerate coating processes, while an integrated cooling system optimizes the enlargement of the dragees. The thermoregulator on the control panel allows for meticulous temperature adjustments, ensuring perfect product polishing. With a tank capacity of 20 kg and an hourly throughput matching its capacity, the Comfit supports seamless integration into your production line. It also offers an option to connect to the SpraySystem for automatic chocolate application, plus an interchangeable air filter for efficient maintenance.

Benefits

- Enhances product quality with precise coating and polishing capabilities.

- Optimizes production efficiency with seamless temperature control and rapid air exchange.

- Boosts operational versatility by accommodating a wide range of confectionery types.

- Simplifies maintenance through easy access to interchangeable filters.

- Integrates effortlessly into existing production lines, reducing setup time.

- Applications

- Snacks, Sugar confectionery, Confectionery, Sweets, Chocolate coating, Sugar coating, Chocolate dragees

- End products

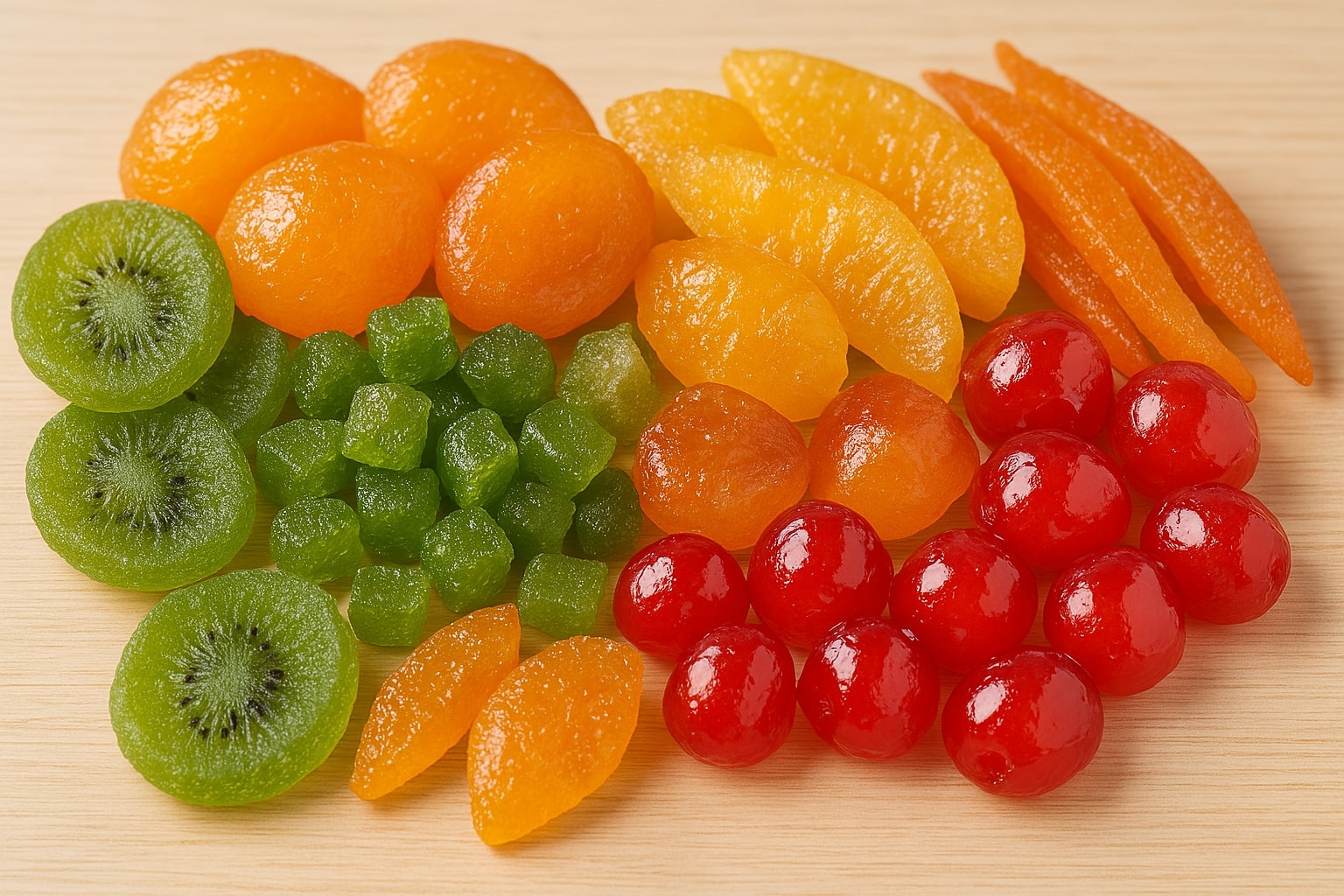

- Chocolate-covered coffee beans, Sugar-coated candies, Sugar-coated chocolate buttons, Praline bonbons, Yogurt-covered nuts, Chocolate-covered peanuts, Chocolate-covered almonds, Candied fruits

- Steps before

- Grinding, Cooling

- Steps after

- Polishing, Cleaning, Cooling, Packing

- Input ingredients

- chocolate, sugar, compressed air

- Output ingredients

- chocolate dragees, sugar confectionery, polished product

- Market info

- Selmi is renowned for manufacturing high-quality chocolate processing equipment, such as tempering, enrobing, and cooling machines, with a strong reputation for precision, innovation, and reliability in the confectionery and chocolate industry.

- Material

- AISI 304 steel

- Automation

- Electronic speed control

- Power required

- 1.8 Kw - 16 A - 3 poles

- Capacity

- 20 kg

- Hourly production rate

- About 20 kg/h

- Cooling unit capacity

- 1100 frigories/h

- Dimensions

- 720x1100x1500 mm (LxWxH)

- Temperature control

- Thermoregulator

- Working mechanism

- Rotating tank with speed control

- Interchangeability

- Interchangeable air filter

- Temperature control

- Thermoregulator on control panel

- Automation level

- Manual/Automatic SpraySystem option

- Air control

- Rapid change between cold and hot air

- Cooling system

- Cooling unit integrated

- Cleaning method

- Automated smoothening and polishing

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 720x1100x1500 mm

- Tank capacity

- 20 kg

- Control panel type

- Electronic with thermoregulator

- Cooling system

- Integrated cooling unit

- Air system

- Interchangeable air filter

- Spray system compatibility

- Automatic SpraySystem