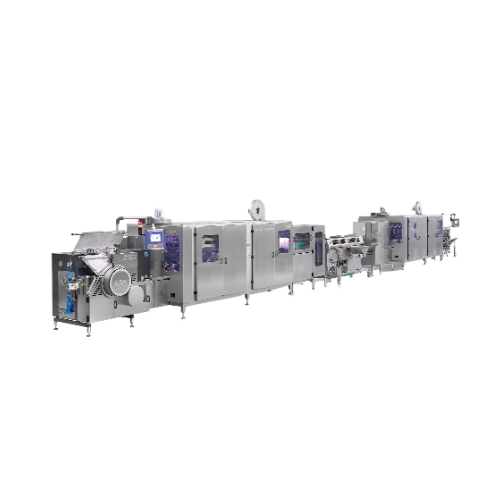

Coated lollipop production line

Transform your confectionery line with a solution that forms, cools, and coats 3D lollipops at unrivaled speeds, maintaining intricate designs while adding dynamic flavors with seamless integration into your production process.

Forms, Coats, and Wraps 3D Lollipops

The GEA Aquarius Coating Line is a fully automated solution from GEA, designed specifically for confectionery producers seeking versatility in their lollipop production. It efficiently forms, coats, and wraps 3D and center-filled lollipops, producing up to 600 pieces per minute. Utilizing a patented take-over transfer wheel, it seamlessly transitions lollipops from forming to cooling, ensuring design integrity and reducing operational downtime with an integrated Clean-In-Place system. This line is tailored for food and candy manufacturing environments, capable of precise powder coating and offering a variety of stick and wrapping materials. Its continuous chain dipping and cooling systems maintain product consistency, while automated lubrication and protective enclosed housings enhance durability and reduce maintenance needs. Customization options allow producers to switch between different shapes and coatings quickly, ensuring adaptability across diverse product lines.

Benefits

- Enhances production flexibility with quick changeovers for different lollipop shapes and coatings.

- Minimizes labor and operational costs through fully automated, continuous processing.

- Preserves lollipop integrity and design detail with precise gripper and cooling mechanisms.

- Reduces cleaning time and contamination risk using the integrated Clean-In-Place system.

- Supports high-speed production, achieving up to 600 lollipops per minute to meet increased demand.

- Applications

- Sweets, Coating materials, Snacks

- End products

- Sandwich wrapped lollipops, 3d hard candy lollipops, Powder-coated lollipops, Center-filled lollipops, Flavored powder-coated lollipops

- Steps before

- Mixing ingredients, Heating syrup, Flavoring

- Steps after

- Coating, Cooling, Wrapping, Packing

- Input ingredients

- 3D shaped hard candy lollipops, center filled hard candy, various shaped lollipops, powders for coating, sticks (PVC, PP, Paper, Wood), wrapping material (Cellophane, Polypropylene, PVC), water for dipping

- Output ingredients

- coated 3D lollipops, wrapped 3D lollipops, solid or center filled lollipops, lollipops with added tastes, colors, and flavors, sandwich-wrapped lollipops

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Speed

- 450 to 600 lollipops / min

- Diameter/width lollipop

- 22 - 32 mm

- Minimum rim ball lollipops

- 4 mm

- Minimum rim 3D lollipops

- 2 mm

- Diameter stick

- 3.2 - 5.5 mm

- Stick length

- 74 - 102 mm

- Stick material

- PVC, PP, Paper, Wood

- Wrapping material

- Cellophane, Polypropylene, PVC

- Automation

- Fully automated

- Coating system

- Powder-coating with inline chain dipping and grippers

- Cooling system

- Integrated inline chain cooling

- Automated Clean-in-Place system (CIP)

- Yes

- Automated machine damage protection system

- Yes

- Take-over transfer wheel

- Patented

- Working mechanism

- Forming, cooling, coating, wrapping

- Integrated steps

- Seamless inline process

- Automation level

- Fully automated

- CIP/SIP

- Automated CIP system

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- CIP

- Changeover time

- Quick change set for forming set

- Energy efficiency

- Continuous line performance monitoring

- Cleanability

- Automated Clean-in-Place system (CIP)

- Custom lollipop shapes

- 3D

- Lollipop diameter range

- 22 - 32 mm

- Stick length range

- 74 - 102 mm

- Stick material types

- PVC, PP, Paper, Wood

- Wrapping material types

- Cellophane, Polypropylene, PVC

- Control panel type

- HMI/PLC

- Shape customization

- 3D shapes, custom designs

- Filling options

- Solid or center-filled

- Coating material

- Powders of choice

- Stick length compatibility

- 74 - 102 mm

- Stick material compatibility

- PVC, PP, Paper, Wood

- Wrapping style

- SandwichWrap