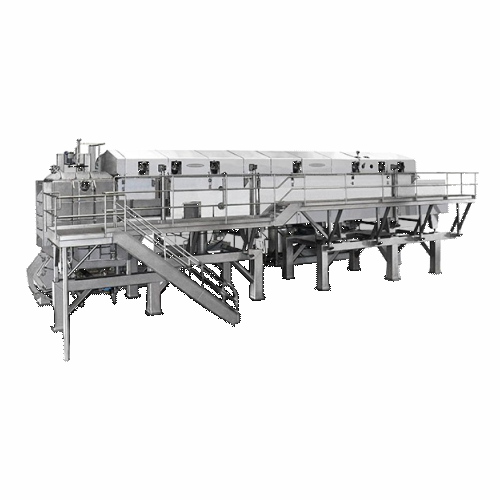

Vacuum fryer for high-sugar snacks

Eliminate the need for an external vacuum chamber while achieving perfect texture and reduced acrylamide levels in high-sugar snacks with this integrated vacuum frying solution.

Controls Oil Temperature and Moisture for Snack Production

The Unitized Vacuum Fryer from Heat and Control offers a unique solution for snack manufacturers and food processing companies. This fryer creates its own internal vacuum, efficiently boiling off product moisture at lower temperatures to produce high-quality snacks from high-sugar products without browning. The integrated centrifuge reduces the finished oil content, ensuring crispier, tastier outputs. Ideal for potato crisps, dried apple rings, and caramelized fruit snacks, the fryer supports continuous high-speed operations vital for snack production. Its PLC-controlled system facilitates seamless integration into existing lines, optimizing energy use by maintaining oil temperatures below 248°F to minimize acrylamide formation. The stainless steel construction provides enhanced durability and corrosion resistance, meeting food industry standards. The fryer is designed for easy access during cleaning and maintenance, streamlining operations while minimizing downtime. Customizable features and engineering support ensure the Unitized Vacuum Fryer adapts to your production needs.

Benefits

- Enhances product quality by preventing browning in high-sugar snacks.

- Reduces acrylamide levels, ensuring healthier snack options.

- Minimizes oil content, delivering crispier, lower-fat products.

- Streamlines cleaning and maintenance, reducing downtime and labor costs.

- Integrates seamlessly into existing production lines with PLC control for increased efficiency.

- Applications

- High sugar products, Apple chips, Snacks, Fruit snacks, Sweet potato/yam snacks, Potato chips

- End products

- Caramelized fruit snacks, Candied yam chips, Potato crisps, Dessert chips, Dried apple rings

- Steps before

- Cutting, Conveying, Blanching

- Steps after

- Packaging, Seasoning, Inspection

- Input ingredients

- potato chips, apple chips, sweet potato, yam snacks, high sugar products

- Output ingredients

- crispy snacks, tastier snacks, flavored fruit snacks, salted fruit snacks, dried fruit snacks

- Market info

- Heat and Control is known for its expertise in manufacturing food processing and packaging equipment, providing innovative solutions and high-quality systems for industries like snacks, prepared foods, and pharmaceuticals, with a strong reputation for reliability and technical support.

- Frying temperature

- Below 248°F

- Oil content reduction

- Integrated centrifuge

- Vacuum creation

- Internal vacuum system

- Product fineness

- Minimizes acrylamide formation

- Cleaning accessibility

- Easily accessible for cleaning

- Working mechanism

- Vacuum frying

- Integrated steps

- Internal vacuum creation

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Easy access for cleaning

- Energy efficiency

- Lower frying temperatures

- Corrosive resistance (e.g. acids)

- Yes

- Abrasion resistance

- Yes

- Cleanability

- Easy to clean

- Density/particle size

- 0.5–1.5 g/cm³ / Medium size

- Product moisture level

- Low temperature boiling

- High sugar content

- Yes

- Compact footprint

- Eliminates external vacuum chamber

- Internal vacuum system

- Integrated into unit

- Discharge method

- Centrifugal separation

- Internal vacuum system

- Integrated

- Centrifuge system

- Integrated

- Cleaning accessibility

- Easy-accessible

- Control panel type

- PLC-controlled