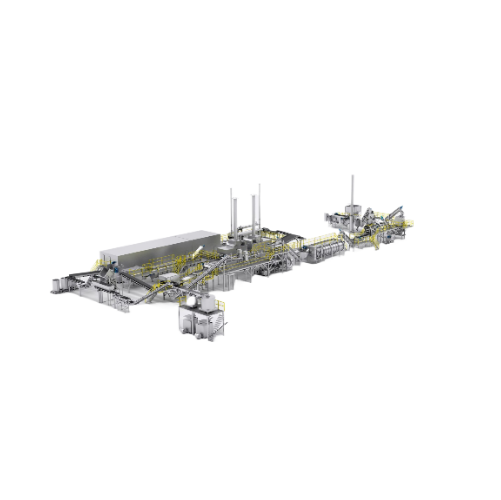

French fry production line

Optimize your French fry production with a seamless line that ensures precise cutting, consistent texture, and efficient frying, reducing waste and improving final product quality for various potato snacks.

Processes Potatoes into Various French Fry Styles

The French fry line from Tummers Food Processing Solutions efficiently transforms potatoes into a variety of fry styles, tailored to meet specific production needs. This turnkey system incorporates advanced equipment, including steam peelers, hydro-cutting systems, and multi-zone fryers, to ensure precision at every stage of processing. Applications range from creating straight and crinkle cut fries to more specialized products like coated and individually quick frozen (IQF) fries. With a focus on sustainability, the line reduces raw material and energy consumption and integrates seamlessly into existing operations via continuous, high-speed processing capabilities.

The system’s modular design allows for significant customization, supporting capacities to align with diverse operational scales. Equipped with PLC controls and remote monitoring, it offers enhanced automation for optimized production flow. Corrosion-resistant materials ensure longevity and compliance with hygiene standards. Additionally, Tummers provides comprehensive engineering support for system customization, as well as thorough employee training for smooth operation and maintenance. This line is ideal for food manufacturers aiming to improve production efficiency and product consistency while maintaining an environmentally responsible footprint.

Benefits

- Enhances product consistency with precise moisture and oil control.

- Increases production efficiency with continuous high-speed operation.

- Reduces environmental impact through optimized energy and raw material consumption.

- Offers scalability and customization for diverse production requirements.

- Minimizes operational costs with durable materials and reduced maintenance needs.

- Applications

- Potato products, Food processing, French fries, Snacks

- End products

- Crinkle cut french fries, Battered fries, Potato wedges, Iqf (individually quick frozen) french fries, Straight cut french fries, Coated fries, Curly fries

- Steps before

- Sorting, Pre-grading, Destoning, Washing, Steam Peeling, De-skinning, Inspecting, Cutting, Blanching

- Steps after

- Defatting, Freezing, Packing

- Input ingredients

- potatoes, oil, batter, peel waste

- Output ingredients

- French fries, golden French fries, coated fries, curly fries, straight fries, packaged French fries

- Market info

- Tummers is known for its expertise in manufacturing industrial engineered-to-order equipment, particularly for the potato processing industry, including peeling, cutting, and frying systems. They are reputed for innovation, quality, and customized solutions in food processing technology.

- Automation

- PLC-controlled

- Moisture Content Control

- Even distribution

- Sizing Accuracy

- Desired length

- Cutting System

- Hydro or mechanical cutting

- Blanching System

- Multiple screw blanchers

- Temperature Control

- Multi-zone frying

- Freezing System

- IQF-Tunnel

- Energy Consumption

- Low

- Water Consumption

- Low

- Waste Reduction

- High

- Sustainability

- Innovative design

- Working Mechanism

- Hydro-Cutting / Mechanical Cutting

- Integrated Steps

- Preparation, Peeling, Cutting, Blanching, Drying, Frying, Freezing, Packing

- Batch vs. Inline Flow

- Inline Continuous

- Automation Level

- Automated with PLC-controlled Systems

- Energy Efficiency

- Optimized for Low Consumption

- Moisture Control

- Equilibration Belt for Even Moisture Content

- Oil Flow Control

- Controlled via Multizone Frying Design

- Changeover Time

- Minimized through Integrated Systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product shape

- Straight / Curly

- Footprint

- Customizable per line

- Process Stages

- Preparation, Steam Peeling, Cutting, Blanching, Drying, Frying, Freezing, Packing

- Material Flow

- Linear, continuous

- Belt System

- Screw blanchers, Multi-zone frying belts

- Installation Type

- Turnkey delivery

- Control panel type

- Programmable Logic Controller (PLC) / HMI

- Customization of line design

- Multizone frying / Optional drying