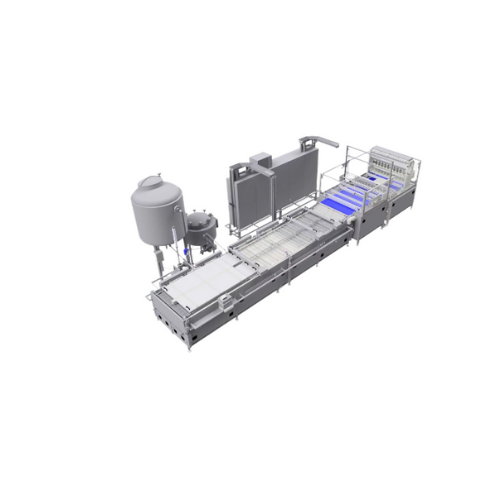

Industrial continuous frying system for donuts and pastries

Achieve artisanal-quality frying with high-volume efficiency, minimizing fat absorption while ensuring consistent results for donuts and pastries.

Frys and Processes High-Volume Bakery Products

The IDA 1100-40 from WP Lebensmitteltechnik RIEHLE GmbH is an industrial continuous frying system designed to meet the demands of high-volume commercial and industrial bakeries. This system stands out for its ability to produce artisan-quality donuts and pastries while ensuring efficient and fully automatable operation. It employs intelligent temperature control and a unique steam lid to minimize fat absorption and optimize product volume. The IDA 1100-40 is versatile, handling a range of bakery products like Berliner donuts, crullers, and curd cheese dumplings with throughput capabilities of up to 8,000 donuts per hour.

This fully integrated system features modular input configurations, such as cloth feeding tables and automatic loaders, and offers remote monitoring and control through a robust touch panel. Its advanced fat and oil management system includes continuous filtration and automatic level control, improving operational efficiency and reducing maintenance requirements. Additionally, the IDA 1100-40 is designed with separate heating zones and a hydraulic lifting unit for easy cleaning and maintenance, catering to the stringent demands of the food and bakery industries. Customizable options are available to suit specific product and production line needs, ensuring seamless integration within your existing setup.

Benefits

- Maximizes production with up to 8,000 donuts per hour capacity.

- Enhances product quality by minimizing fat absorption with intelligent temperature control.

- Reduces operational downtime and costs through remote monitoring and maintenance capabilities.

- Supports versatile production needs with customizable input systems and configurations.

- Simplifies cleaning and maintenance with hydraulic lifting and tool-free removable components.

- Applications

- Berliner donuts, Curd cheese dumplings, Pastries, Donuts, Bakery products

- End products

- Filled donuts, Fritters, Ball donuts, Curd balls, Cake donuts, Sugared donuts, Pretzel lye application pastries, Crullers

- Steps before

- Proofing, Dough preparation, Mixing, Shaping

- Steps after

- Cooling, Sugaring, Decorating, Packaging

- Input ingredients

- Berliner donut batter, curd cheese dumplings batter, dough for donuts, crullers batter, cake-donuts batter, frying oil or fat

- Output ingredients

- Berliner donuts, donuts, curd cheese dumplings, fried crullers, fried cake-donuts

- Market info

- Speed

- Up to 8, 000 donuts per hour

- Capacity

- Up to 4, 000 Berliner donuts per hour

- Automation

- Fully automatable

- Temperature Control

- Intelligent temperature control

- Input Systems

- Modular, includes cloth feeding table, automatic loader

- Turning Process

- Controlled by servomotors

- Remote Maintenance

- Possible via LAN or WLAN

- Fat/Oil Management

- Continuous filtration, automatic level control

- Decoration

- 10-fold filling, sugaring, powdering

- Heating Zones

- Controlled independently

- Feeding Systems Configurable

- One or more feeding systems

- Control System

- Intuitive touch glass display

- Automation level

- Fully Automatable

- Network capability

- LAN / WLAN

- Remote Monitoring

- Enabled

- Fat/Oil Management

- Continuous Filtration, Automatic Level Control

- Touch Control

- Intuitive Operation

- Batch vs. continuous operation

- Continuous

- Energy Efficiency

- Minimized Fat Absorption

- Heating Zones

- Independently Controlled

- Cleaning Method

- Heated Drain/Cleaning Cloth

- Data Access

- Remote Access Available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed/discharge method

- Cloth feeding table, automatic loader, discharge via return conveyor

- Control panel type

- Intuitive touch control

- Control panel type

- Intuitive touch control

- Integration possibilities

- Can be networked with LAN or WLAN

- Remote maintenance

- Technical support can be provided remotely

- Automation level

- Fully automatable

- Modular input systems

- Cloth feeding table, automatic loader, system trolleys

- Fat / oil management system

- Continuous fat/oil filtration, automatic level control