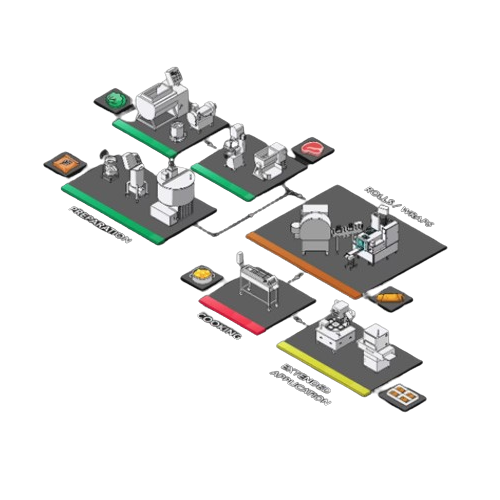

Spring roll manufacturing line

Optimize your spring roll production with an advanced manufacturing line that ensures consistent quality, from sieving and forming to frying and packing, all while preserving the integrity of diverse fillings.

Forms, Fries, and Packs Spring Rolls

The SR-27 machine and SRPF production line from ANKO redefine commercial spring roll production with a seamless integration of forming, frying, and packing processes. Designed to tackle the challenges of high-volume food manufacturing, this equipment ensures consistent dough texture and filling preservation through a unique filling mechanism that mimics handmade techniques. Capable of producing up to 1.4 spring rolls per second, the SR-27 features a water-resistant design for easy cleaning, coupled with a high-capacity 50-liter filling hopper for uninterrupted operation. The line is PLC-controlled for full automation, allowing remote monitoring and real-time adjustments, thus optimizing both energy use and labor efficiency. Its versatility accommodates a wide variety of fillings, from cabbage and bean sprouts to proteins like shrimp and pork, making it a staple in large-scale food processing and frozen food industries. Customizable texture options and adjustable wrapping tightness cater to diverse customer preferences, while built-in IoT capabilities offer unmatched control and productivity in an industrial setting. ANKO’s spring roll solutions are engineered to meet the highest standards of quality and hygiene, providing robust support to ensure your production line runs smoothly with minimal downtime.

Benefits

- Enhances production efficiency with high-speed output of 1.4 spring rolls per second.

- Maintains consistent product quality through precise control of wrapper thickness and filling integrity.

- Reduces cleaning time with water-resistant design for easy sanitation.

- Optimizes labor efficiency through full automation and remote monitoring capabilities.

- Offers flexibility in product variety with customizable wrapping tightness and diverse filling options.

- Applications

- Ready meals, Bao, Shumai, Spring rolls, Dumplings, Samosas, Mochi

- End products

- Chicken shumai, Bean sprout spring rolls, Tofu ready meals, Shrimp dumplings, Pork samosas, Red bean mochi, Mixed vegetable spring rolls, Vegetarian bao, Cabbage spring rolls

- Steps before

- Sieving, Flour separation, Flour filtering

- Steps after

- Packing, Aligning, Frying, Freezing

- Input ingredients

- flour, water, shredded cabbage, bean sprouts, mixed vegetables, spring roll batter

- Output ingredients

- spring roll wrappers, filled spring rolls, deep-fried spring rolls, packaged spring rolls

- Market info

- The Food Machinery Company Ltd. is known for manufacturing bespoke food processing equipment, like conveyors and mixers, offering engineering expertise for industrial-scale food production, backed by a reputation for quality and tailored solutions in the UK and international markets.

- Production Speed

- 1.4 seconds per spring roll

- Capacity

- High-capacity filling hopper 50 litres per cycle

- Wrapper Thickness

- Uniform size and thickness

- Temperature Control

- Precise digital controller for frying

- Automation

- User-friendly control panel, built-in IoT system

- Water Resistant Design

- Yes, for parts in contact with food

- Working mechanism

- Fully automated

- Integrated steps

- Sieving, forming, frying, packing

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled with IoT system

- Changeover time

- Minimal due to automated systems

- Cleaning method

- Manual

- Water-resistant design for easy cleaning

- Energy efficiency

- High efficiency with digital controllers

- User-friendly Control Panel

- Intuitive interface

- Production speed

- 1.4 seconds per spring roll

- Wrapper thickness

- Uniform

- Wrapper size

- Customizable

- Filling hopper capacity

- 50 litres

- Discharge method

- Conveyor system

- Control Panel Type

- User-friendly, IoT-enabled

- Spring Roll Tightness

- Adjustable

- Wrapper Texture

- Customizable