Potato chip production line

Achieve consistent, high-quality potato chips with a seamlessly integrated line that optimizes every stage from pre-cleaning to flavoring, ensuring minimal waste and maximum efficiency in your production process.

Processes and Refines Potato-Based Products

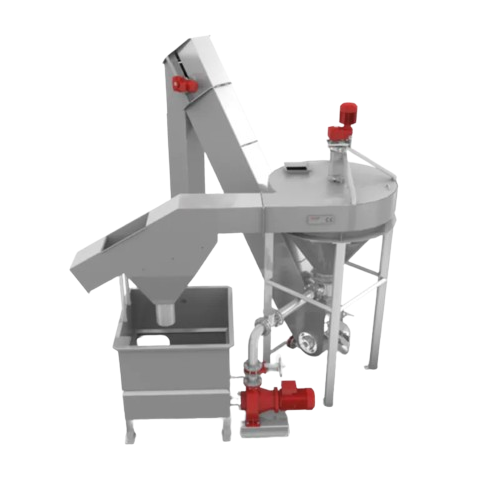

Kiremko’s Potato Chip Processing Line is tailored for snack manufacturers and food production companies aiming for seamless integration into existing facilities. This system stands out with its capacity to handle multiple potato snack varieties, including chips and fries, at up to 70 tons per hour. The equipment line encompasses cyclone destoners and drum washers for optimal pre-cleaning, abrasive peelers for precision peeling, and innovative cutting tools like the FAM Centris™ slicer for uniform chip production.

The Hi-Flow blancher and advanced frying systems improve the quality and consistency of the end products by accurately controlling blanching times and maintaining optimal frying temperatures. Kiremko’s fryers feature an insulated hood to minimize energy loss, and a controlled oil supply system ensures to prevent over-oxidation.

Automation is a key feature, with PLC-control and remote monitoring enabling streamlined operations, while the WeighGuard system ensures precise flavor dosing for consistent output. The equipment is constructed from robust materials offering excellent resistance to wear, ensuring longevity and minimal maintenance. Furthermore, the system supports CIP (Clean-In-Place) for efficient cleaning, minimizing downtime and contamination risks. With Kiremko’s customization options, processing lines can be tailored to meet specific production needs, backed by engineering support for optimal deployment.

Benefits

- Enhances production efficiency with continuous, high-speed operation.

- Minimizes energy consumption through optimized oil supply and insulation.

- Ensures consistent product quality with precise slicing and frying controls.

- Reduces labor and maintenance costs with easy-access, integrated CIP systems.

- Customizable configurations support diverse snack product lines and capacities.

- Applications

- Hash browns, Flake products, Pellet snacks, Potato chips, Formed mash, French fries

- End products

- Barbecue flavored chips, Vegetable blended snack pellets, Tater tots, Wavy potato chips, Breaded potato nuggets, Ketchup flavored chips, Curly fries, Patty hash browns, Potato-based snack pellets, Crinkle-cut fries, Waffle fries, Potato flakes for instant mashed potatoes, Formed mash potato products, Salt and vinegar chips, Sweet potato fries, Shredded hash browns, Flake potato products, Dehydrated potato flakes

- Steps before

- Pre-cleaning, Peeling, Cutting

- Steps after

- Flavouring, Packing

- Input ingredients

- potatoes, raw potatoes, natural potatoes

- Output ingredients

- potato chips, fried potato chips, flavored potato chips

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Capacity

- Up to 70 tons per hour

- Peeling accuracy

- Depth measured to within millimeters

- Cutting speed

- 10–14 m/s

- Blanching control

- Accurate time and temperature setting

- Fryer temperature control

- Consistently high temperature

- Flavouring accuracy

- Accurate dosing

- Water flow optimization

- Specific design of rinse basin

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Easy maintenance / CIP

- Energy efficiency

- Low energy consumption

- Integrated steps

- Pre-cleaning, peeling, cutting, blanching, frying, flavouring

- Working mechanism

- Consistent quality production

- Abrasion resistance

- Stainless steel components

- Corrosive resistance (e.g. acids)

- Polyurethane layer

- Cleanability

- Easy maintenance design

- Density/particle size

- Handles wide range of potato sizes

- Foaming

- Low

- Compact footprint

- No

- Discharge method

- Continuous

- Materials

- Stainless Steel

- Machine Size

- Customizable

- Construction Material

- Polyurethane Coating

- Control panel type

- PLC with HMI

- Integration possibilities

- SCADA, IoT integration

- Capacity customization

- Up to 70 tons per hour

- Material options

- Stainless steel, polyurethane layer

- System accessibility

- Easy maintenance access

- Blanching configuration

- Adjustable time and temperature settings